A kind of heavy metal contaminated soil remediation material and its preparation method and use method

A technology for remediation materials and polluted soil, applied in the field of remediation materials for heavy metal contaminated soils and their preparation, can solve the problems of poor separation effect between remediation materials and soil, increase soil pollution, increase organic matter, etc. Simple, strong adsorption and fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of heavy metal polluted soil remediation material, its preparation method comprises the following steps:

[0049] (1) crushing and ball milling the ilmenite tailings to obtain 100% ilmenite powder of -325 mesh;

[0050] (2) crushing and ball milling the carbon black to obtain 100% carbon black powder of -325 mesh;

[0051] (3) 70 parts of ilmenite powder in the step (1) are mixed with 30 parts of the carbon black powder in the step (2) to obtain a compound, and adding 20 parts of mass concentration to the compound is 30% silica sol and 10 parts of γ-mercaptopropyltrimethoxysilane modification solution with a mass concentration of 15%, stir evenly, and obtain a columnar repair material precursor with an average diameter of φ1mm by extrusion;

[0052] (4) Heat the repair material precursor in step (3) to 75°C at a heating rate of 3°C / min in a vacuum drying oven, keep it warm for 1.5h, and then raise the temperature to 105°C at a rate of 7°C / min , heat preservatio...

Embodiment 2

[0054] A kind of heavy metal polluted soil remediation material, its preparation method comprises the following steps:

[0055] (1) crushing and ball milling the ilmenite tailings to obtain 100% ilmenite powder of -325 mesh;

[0056] (2) crushing and ball milling the carbon black to obtain 100% carbon black powder of -325 mesh;

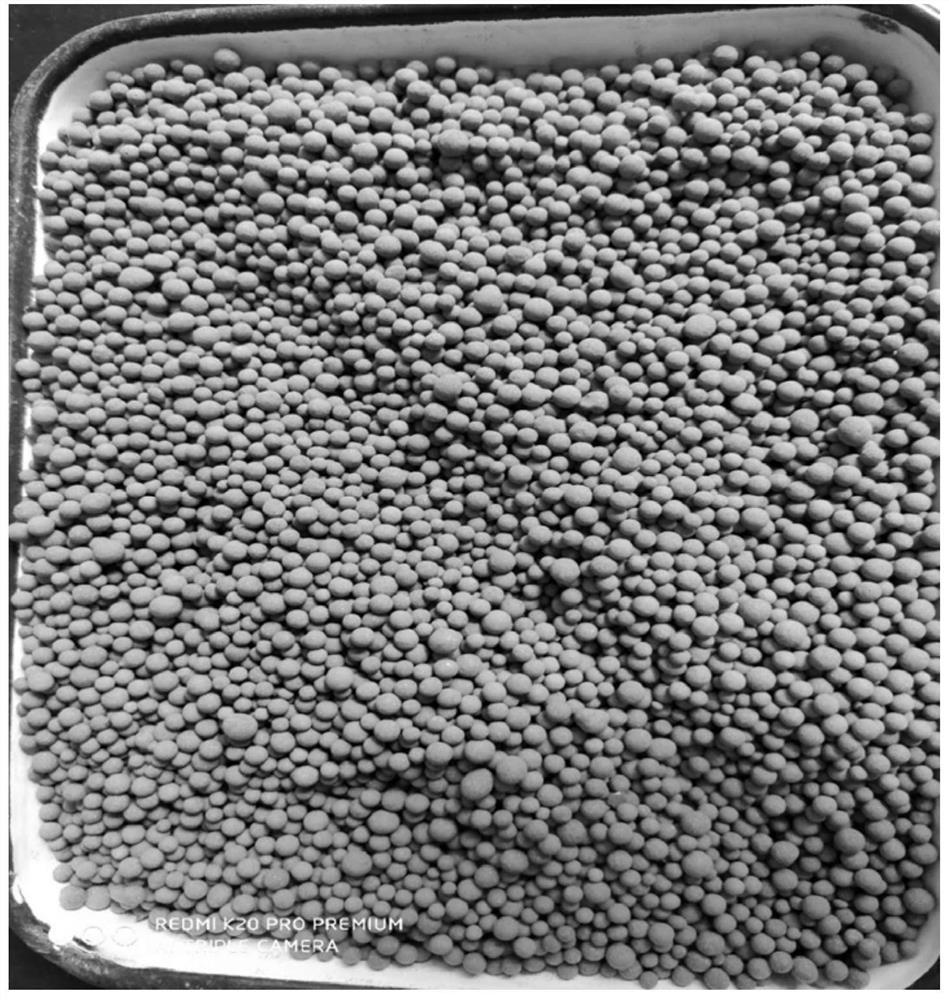

[0057] (3) 60 parts of ilmenite powder in the step (1) are mixed with 30 parts of the carbon black powder in the step (2) to obtain a mixture, and adding 10 parts of mass concentration to the mixture is 40% silica sol and 8 parts of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane modified liquids with a mass concentration of 20%, stir evenly, and obtain an average particle diameter of φ3mm by disc granulation. Spherical repair material precursor;

[0058] (4) Heat the repair material precursor in step (3) to 70°C at a heating rate of 3°C / min in a vacuum drying oven, keep it warm for 1.5 hours, and then raise the temperature to 105°C at a rate of...

Embodiment 3

[0060] A kind of heavy metal polluted soil remediation material, its preparation method comprises the following steps:

[0061] (1) crushing and ball milling the ilmenite tailings to obtain 100% ilmenite powder of -325 mesh;

[0062] (2) crushing and ball milling the carbon black to obtain 100% carbon black powder of -325 mesh;

[0063] (3) 80 parts of ilmenite powder in the step (1) are mixed with 50 parts of the carbon black powder in the step (2) to obtain a mixture, and adding 10 parts of mass concentration to the mixture is 35% silica sol and 5 parts of γ-aminopropyltriethoxysilane modification solution with a mass concentration of 25%, stir evenly, and obtain a φ2mm spherical repair material precursor by disc granulation;

[0064] (4) Heat the repair material precursor in step (3) to 80°C at a heating rate of 2°C / min in a vacuum drying oven, keep it warm for 1 hour, and then raise the temperature to 110°C at a rate of 10°C / min. Insulated for 1h, cooled and prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com