Preparation method of fermented plum refined extract

A technology of fermented products and plums, which is applied in the field of preparation of fermented plum extracts, can solve the problems of poor plum extraction effect, poor sensory effect, weak and rough fragrance, etc., achieve good sensory effect, reduce the number of molds, and improve aroma The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

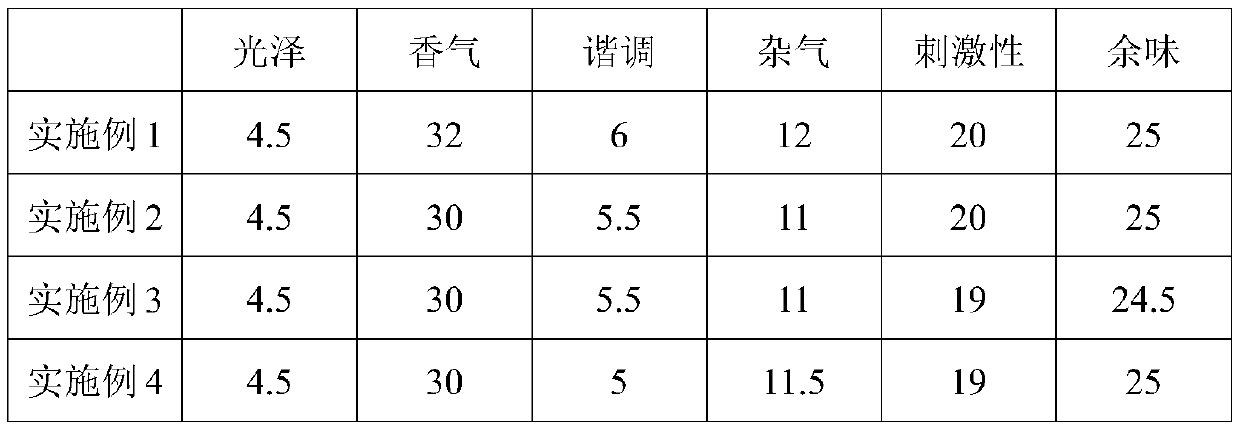

Embodiment 1

[0018] A method for preparing fermented plum essence extract, inoculating Debaria hansenii and Kluyveromyces marx into plum culture medium at a mass ratio of 1:2.5 for fermentation, the fermentation temperature is 28°C, and after 6 days, the obtained The fermented product is extracted, and the extract is added to the fermented product. The volume ratio of the fermented product and the extract is 1:4.5, extracted for 3 hours, then centrifuged at 9000rpm, and the supernatant is taken to obtain the fermented plum extract; The extract solution includes isoamyl alcohol and ethyl acetate with a volume ratio of 1:2.4.

[0019] The bacterial concentration of Debaria hansenii was 5×10 6 CFU, the bacterial concentration of Kluyveromyces marx is 5×10 6 CFU, the inoculum amount of Debaria hansenii is 1.5% of the quality of the plum culture medium.

Embodiment 2

[0021] A method for preparing fermented plum essence extract, inoculating Debaria hansenii and Kluyveromyces marx into plum culture medium at a mass ratio of 1:2 for fermentation, the fermentation temperature is 30°C, and after 5 days, the obtained The fermented product is extracted, and the extract is added to the fermented product. The volume ratio of the fermented product and the extracted liquid is 1:5, extracted for 2 hours, and then centrifuged at 12000rpm, and the supernatant is taken to obtain the fermented plum extract; The plum culture medium is the plum slurry formed after washing and crushing; the extract includes isoamyl alcohol and ethyl acetate with a volume ratio of 1:2.

[0022] The bacterial concentration of Debaria hansenii was 1×10 7 CFU, Kluyveromyces marxense concentration of 1 × 10 6 CFU, Debaria hansenii inoculum is 2% of the quality of the plum culture medium.

Embodiment 3

[0024] A method for preparing fermented plum essence extract, inoculating Debaria hansenii and Kluyveromyces marx into plum culture medium at a mass ratio of 1:3 for fermentation, the fermentation temperature is 25°C, and after 7 days, the obtained The fermented product is extracted, and the extract is added to the fermented product. The volume ratio of the fermented product and the extracted liquid is 1:4, extracted for 4 hours, and then centrifuged at 8000rpm, and the supernatant is taken to obtain the fermented plum extract; The plum culture medium is the plum slurry formed after washing and crushing; the extract includes isoamyl alcohol and ethyl acetate with a volume ratio of 1:3.

[0025] The bacterial concentration of Debaria hansenii was 1×10 6 CFU, Kluyveromyces marxense concentration of 1 × 10 7 CFU, the inoculum amount of Debaria hansenii is 1% of the quality of the plum culture medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com