A kind of tungsten carbide reinforced steel and its preparation method

A technology of tungsten carbide and steel strengthening, which is applied in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of inaccurate control of size, volume fraction shape and distribution, and affect the strengthening effect of tungsten carbide, so as to achieve low cost, Effects of removal of inclusions and improvement of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

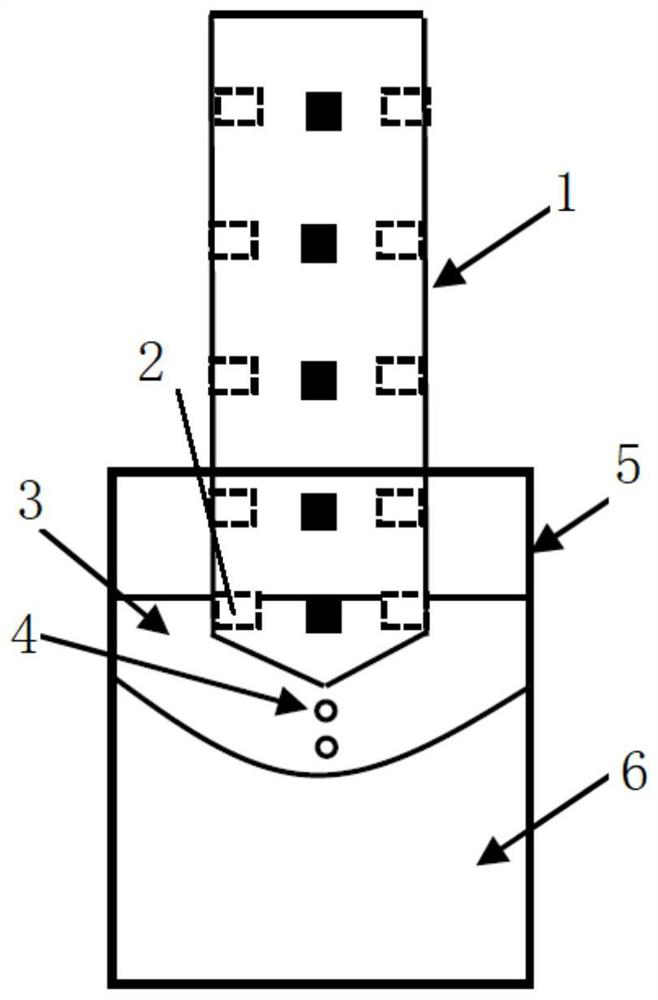

[0033] The preparation method of the tungsten carbide strengthened steel of the present invention mainly comprises three steps of coating of tungsten carbide, encapsulation of tungsten carbide and release and dispersion of tungsten carbide:

[0034] (1) Coating of tungsten carbide

[0035] Put the pure iron powder, tungsten carbide and dispersant in the ball mill to mix the materials, so that the surface of the tungsten carbide powder is coated with a layer of metallic iron.

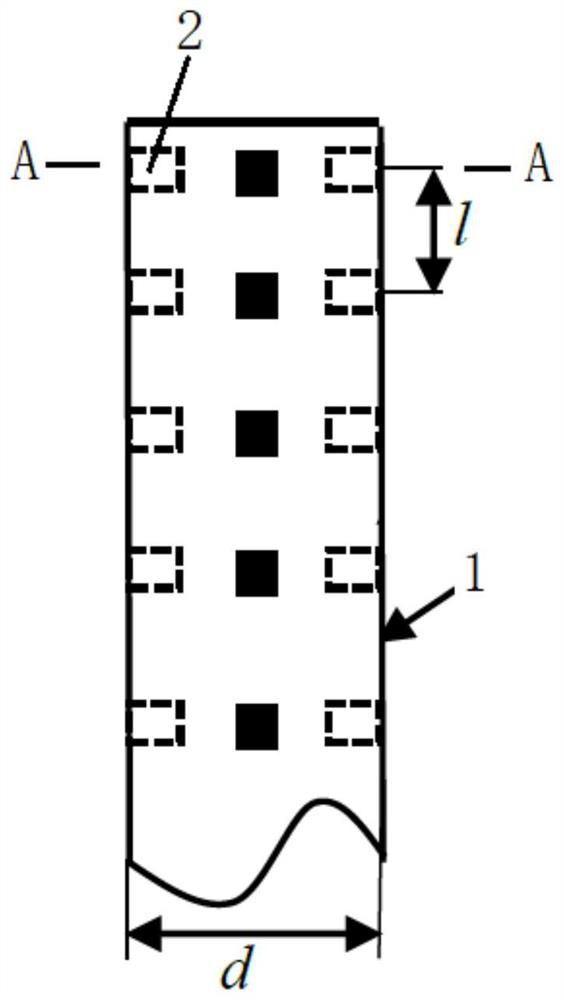

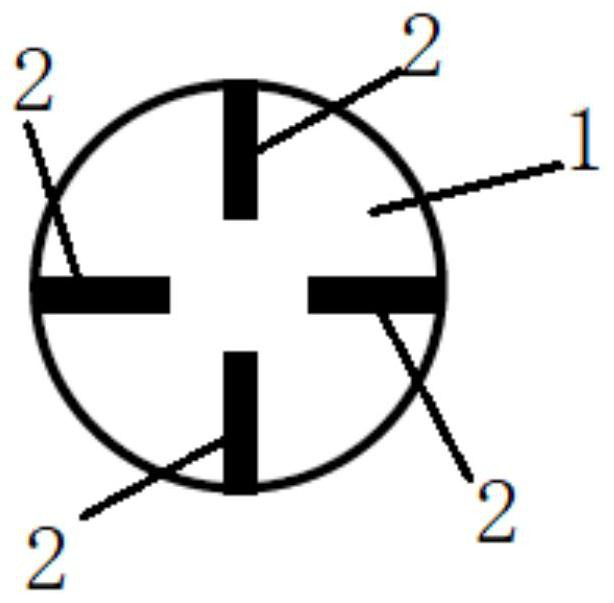

[0036](2) Packaging of tungsten carbide (see Figure 1(a) and Figure 1(b))

[0037] The steel to be strengthened is forged into a round rod electrode 1, and the surface of the round rod electrode 1 is polished; 4N diameters d are drilled on the surface of the round rod electrode 1 0 =1~5mm, depth h 0 = 1 to 2 cm circular packaging holes 2; each group of 4 packaging holes 2 is evenly distributed on the same circumference of the round rod electrode 1, and the round rod electrode 1 is evenly distributed in...

Embodiment 1

[0042] The steel to be strengthened in this embodiment is T91 steel, and the preparation method mainly includes three steps: coating of tungsten carbide, encapsulation of tungsten carbide and release and dispersion of tungsten carbide:

[0043] (1) Coating of tungsten carbide

[0044] Put the pure iron powder, tungsten carbide and dispersant in the ball mill to mix the materials, so that the surface of the tungsten carbide powder is coated with a layer of metallic iron.

[0045] (2) Packaging of tungsten carbide

[0046] Forge T91 steel to be strengthened into a round rod electrode 1 with a diameter of 60mm and a length of 2.5m, and polish the surface of the round rod electrode 1; On the same cross-section of the electrode 1), four circular packaging holes 2 are evenly distributed, and the diameter of the circular packaging hole 2 is d 0 = 2mm, depth h 0 = 1.5cm, the distance between two adjacent rows of packaging holes 2 = 2cm; the coated tungsten carbide powder is divided...

Embodiment 2

[0052] The strength to be strengthened in this embodiment is P92, and the preparation method mainly includes three steps of tungsten carbide coating, tungsten carbide packaging and tungsten carbide release and dispersion:

[0053] (1) Coating of tungsten carbide

[0054] Put the pure iron powder, tungsten carbide and dispersant in the ball mill to mix the materials, so that the surface of the tungsten carbide powder is coated with a layer of metallic iron.

[0055] (2) Packaging of tungsten carbide

[0056] Forge the P92 steel to be strengthened into a round rod electrode 1 with a diameter of 65 mm and a length of 3 m, and polish the surface of the round rod electrode 1; On the same cross-section), four circular packaging holes 2 are evenly distributed, and the diameter of the circular packaging hole 2 is d 0 = 5mm, depth h 0 = 2cm, the distance between two adjacent rows of packaging holes 2 = 5cm; the coated tungsten carbide powder is divided into 60 parts, and each part i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com