Zinc impregnation system

A technology of sherardizing and heating furnace, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the temperature control and processing time can not be uniform, waste of heat energy, temperature control temperature and heat preservation time error and other problems to achieve the effect of improving production efficiency and product quality, ensuring uniform consistency, and uniform and constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

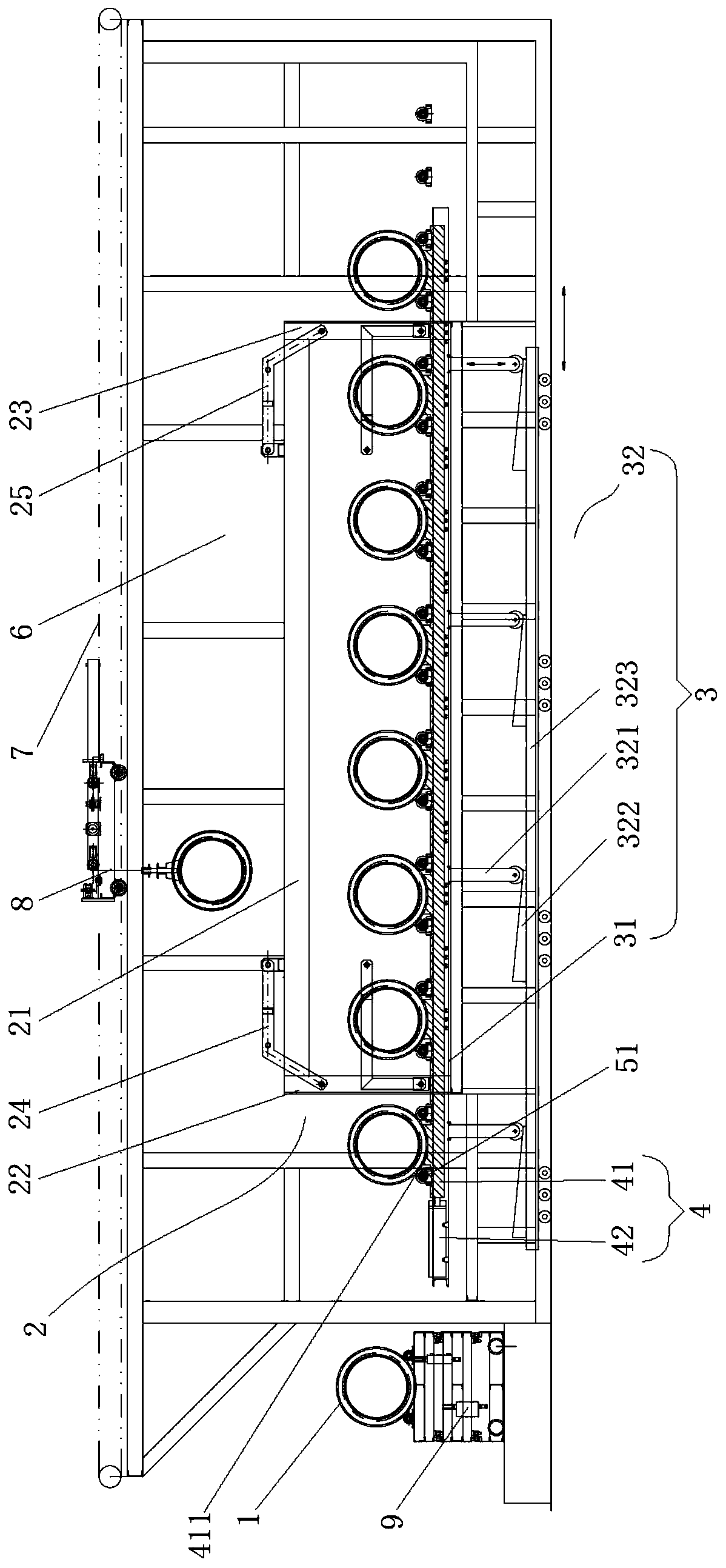

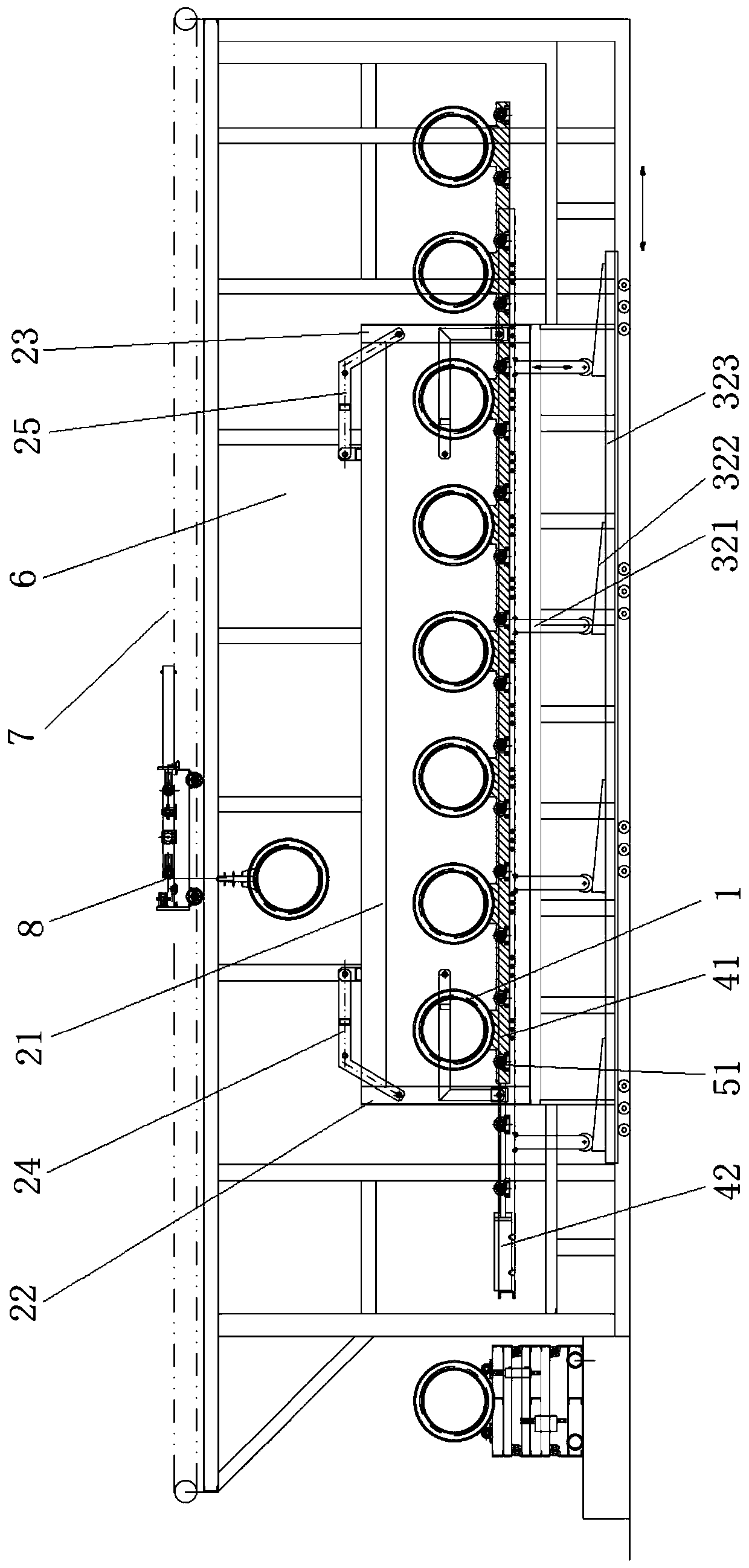

[0034] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. The following orientation terms such as "top" and "bottom" are preceded by figure 1 shown for reference.

[0035] refer to figure 1 and figure 2 , This embodiment provides a sherardizing system. The sherardizing system includes a plurality of sherardizing tanks 1, a through-type heating furnace 2, a lifting mechanism 3, a longitudinal moving mechanism 4, a plurality of sherardizing tank rotation driving mechanisms 5, a cooling zone 6, and a plurality of sherardizing tank temperature measuring devices ( not shown in the figure) and a controller (not shown in the figure).

[0036] Specifically, the zinc sherardizing tank 1 includes a cylindrical barrel with one end open and an end wall connected to the open end of the cylindrical barrel, a through hole is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com