Ammonia gas generation metering spraying device with short response time and spraying rate control system

A technology of response time and injection device, which can be used in exhaust device, muffler device, exhaust gas treatment, etc., and can solve problems such as inaccurate metering injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

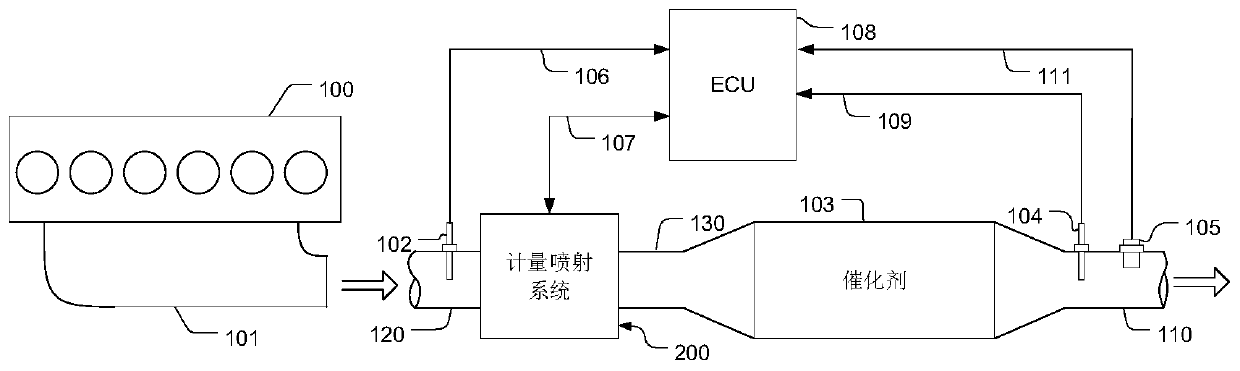

[0082] like figure 1As shown, in the engine system, exhaust gas produced by the engine 100 enters the passage 120 through the manifold 101 . Passage 120 is fluidly connected to ammonia generating metering injection device 200 , which is controlled by engine control unit (abbreviated as ECU) 108 via signal line 107 . The ammonia generating metering injection device 200 delivers and mixes the reductant into the exhaust gas. The mixed exhaust gas flows into the catalyst 103 through the passage 130, where the reducing agent reacts with NOx in the exhaust gas and reduces the NOx. On the channel 120, the third temperature sensor 102 is used to measure the temperature of the exhaust gas upstream of the catalyst 103, and the temperature sensing signal is sent to the ECU 108 through the signal line 106. A fourth temperature sensor 104 is mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com