Fiber reinforced PVC flexible tube

A fiber-reinforced hose technology, applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of easy fracture of bamboo charcoal fiber materials, PVC hose fracture, and reduce the toughness of PVC hose, so as to achieve good strength and improve pressure resistance The effect of strength and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

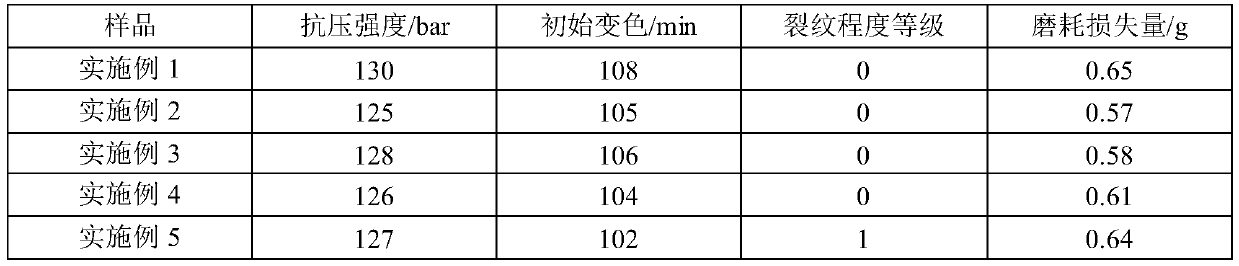

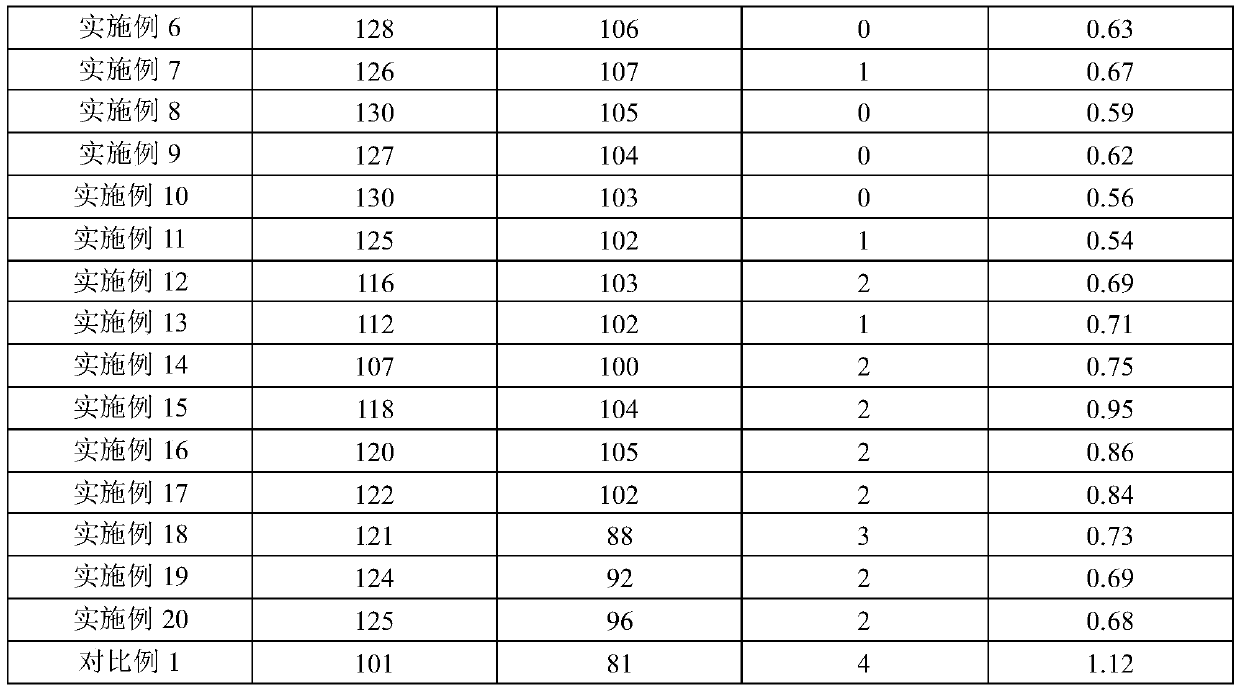

Examples

Embodiment 1

[0032] Embodiment 1 is a fiber-reinforced PVC hose disclosed by the present invention, which sequentially includes a PVC inner layer, a fiber mesh layer and a PVC outer layer from the inside to the outside. The fiber mesh layer is made of compound fibers, and the compound fibers are polystyrene Ethylene / ramie fiber / ABS resin fiber, the mass ratio of polystyrene, ramie fiber and ABS resin is 3:2:12.5;

[0033]The preparation method of polystyrene / ramie fiber / ABS resin fiber is: 1) ramie fiber is pulverized into fiber length and is 3mm, and the fine debris of fiber diameter is 15um standby; 2) polystyrene is dissolved in acetone solution, and then Add the ramie fiber fines into the polystyrene solution, and stir evenly to obtain a blend; 3) heat the ABS resin to a molten state, and then mix 3% of the total weight of the ABS resin with the mica powder in step 2) Add the blend into the ABS resin melt and stir evenly; 4) Extrude the uniformly stirred mixture in step 3) into strips,...

Embodiment 2

[0043] Embodiment 2 is a fiber-reinforced PVC hose disclosed by the present invention. The difference from Embodiment 1 is that the PVC inner layer and the PVC outer layer include the following components in parts by weight: 75 parts of PVC resin, wear-resistant filler 5 parts, 5 parts of anti-aging masterbatch, 4 parts of phthalate and 1 part of polyethylene wax.

Embodiment 3

[0044] Embodiment 3 is a fiber-reinforced PVC hose disclosed by the present invention. The difference from Embodiment 1 is that the PVC inner layer and the PVC outer layer include the following components in parts by weight: 95 parts of PVC resin, wear-resistant filler 15 parts, anti-aging masterbatch 10 parts, phthalate ester 8 parts and polyethylene wax 3 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com