High-field in-situ polarization device and method utilizing parahydrogen to induce polarization

A high-field, in-situ technology, applied in the field of magnetic resonance spectroscopy, can solve problems such as inability to meet application requirements, loss of polarization signals, and impact on the quality of the spectrum, and achieve easy production and maintenance, uniform and stable magnetic field, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

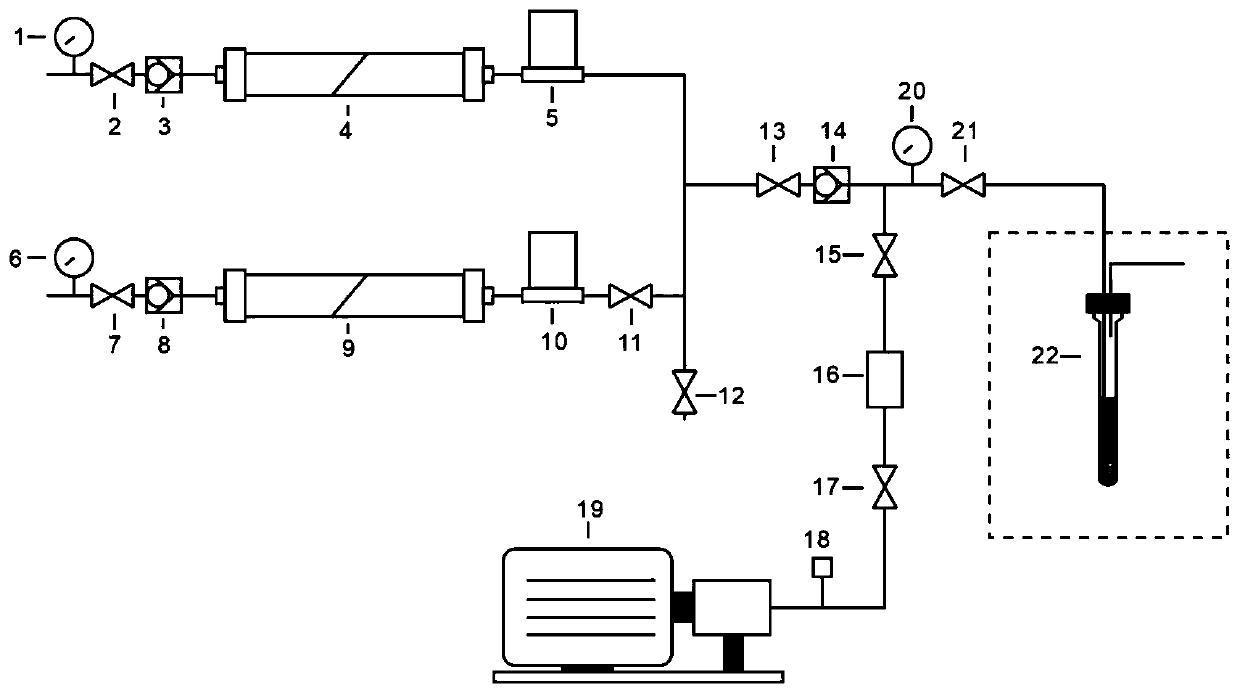

[0039] A high-field in-situ polarization device using parahydrogen-induced polarization, including a vacuum pump 19, including a parahydrogen inlet channel, a reaction gas inlet channel and a reaction sampling tube 22,

[0040]The outlet end of the reaction gas inlet channel is connected to one end of the third through valve 11, and the other end of the third through valve 11 is respectively connected to the outlet end of the parahydrogen inlet channel, one end of the fourth through valve 12 and one end of the fifth through valve 13, The other end of the fifth through valve 13 is connected to the inlet end of the third one-way valve 14, and the outlet end of the third one-way valve 14 is respectively connected to one end of the eighth through valve 21 and one end of the sixth through valve 15, and the eighth through valve 21 The other end is connected to the reaction sampling pipe 22, the other end of the sixth through valve 15 is connected to the vacuum pump 19 through the vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com