Spherical nanometer friction generator unit and net cage based on generator unit

A nano-friction and generator technology, applied in friction generators, engine components, ocean energy power generation, etc., can solve the problems of low wave energy utilization efficiency, difficult installation and maintenance, and low power generation, and achieve wave energy utilization High efficiency, low maintenance difficulty, and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

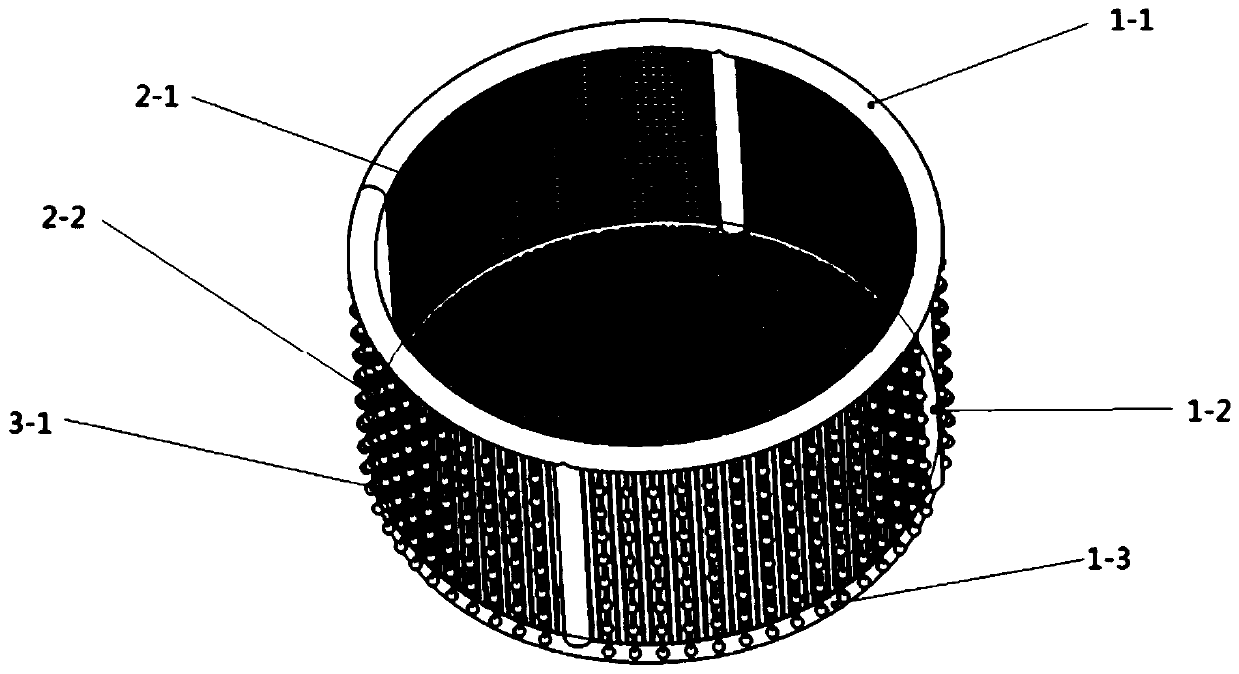

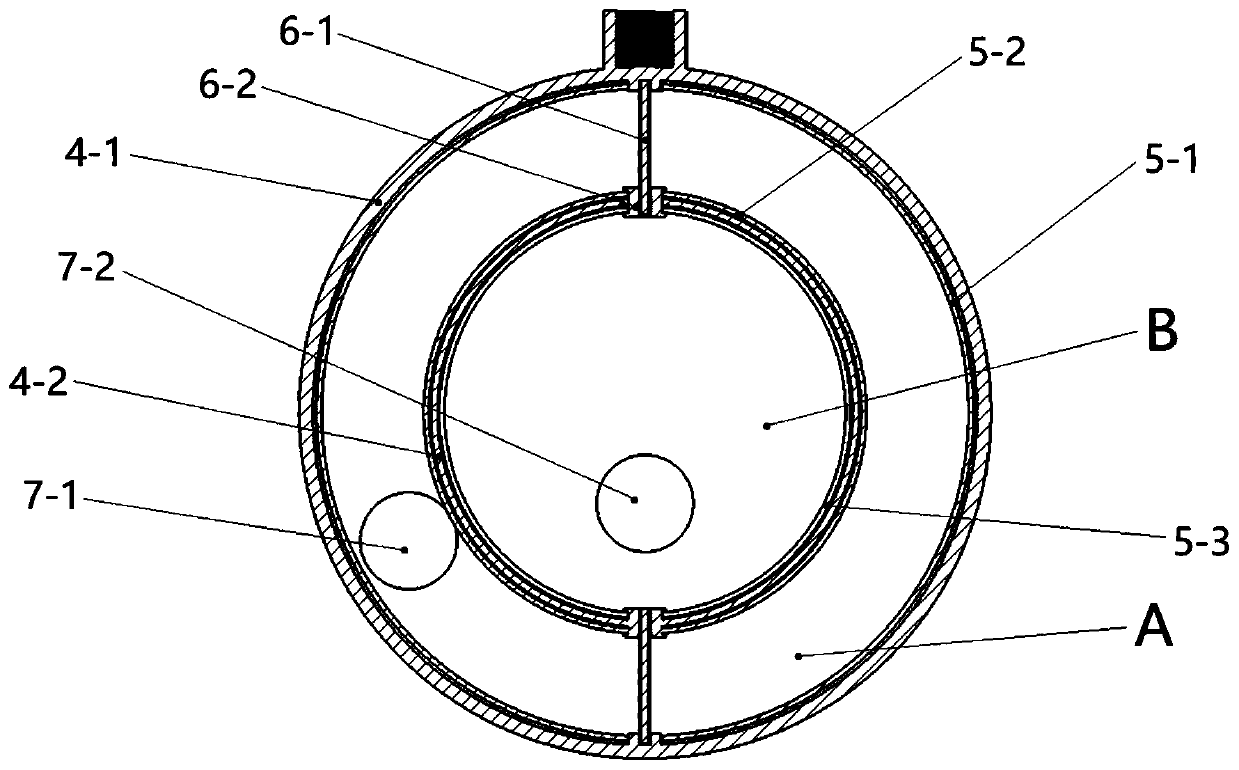

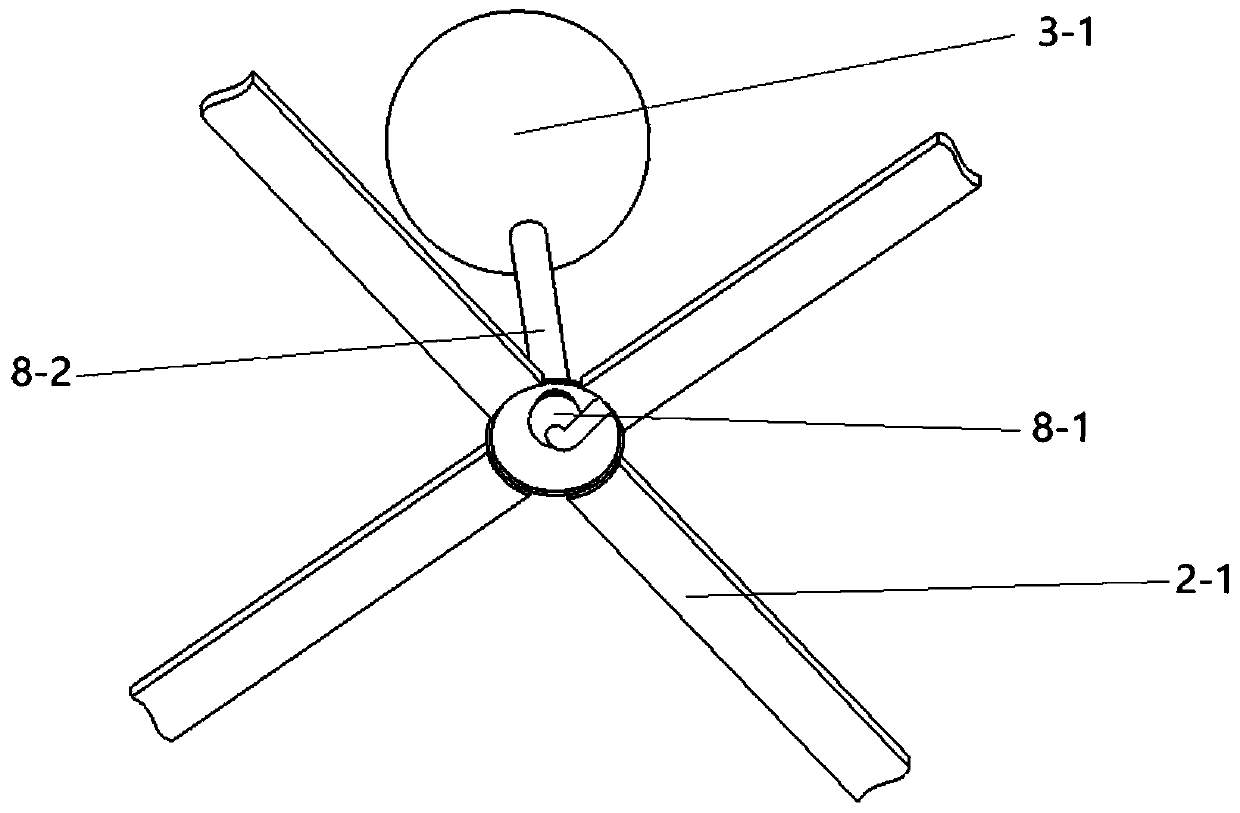

[0024] The invention provides a spherical nano-friction generator unit, combined with the netting of the breeding net cage, provides a self-powered net cage based on the spherical nano-friction generator unit. A net cage based on a spherical nanometer friction generator unit mainly includes three parts: a cylindrical cage frame, double-layer netting and a spherical nanometer friction generator unit. The cage frame is formed by welding the upper and lower annular pipes and four vertical rods arranged symmetrically in a ring in the middle; the double-layer net is composed of four arc-shaped double-layer nets on the side wall and the bottom of the net; The spherical nano-friction generator unit is a fully enclosed spherical structure with a built-in silicone ball, and is connected to the net through a rope combined with a hinge. The invention utilizes a multi-point spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com