Combined desulfurization and denitrification system for sintering flue gas

A technology for sintering flue gas, desulfurization and denitrification, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of less engineering application, large ozone power consumption, high process cost, etc., achieve efficient removal and broad market prospects , High desulfurization and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

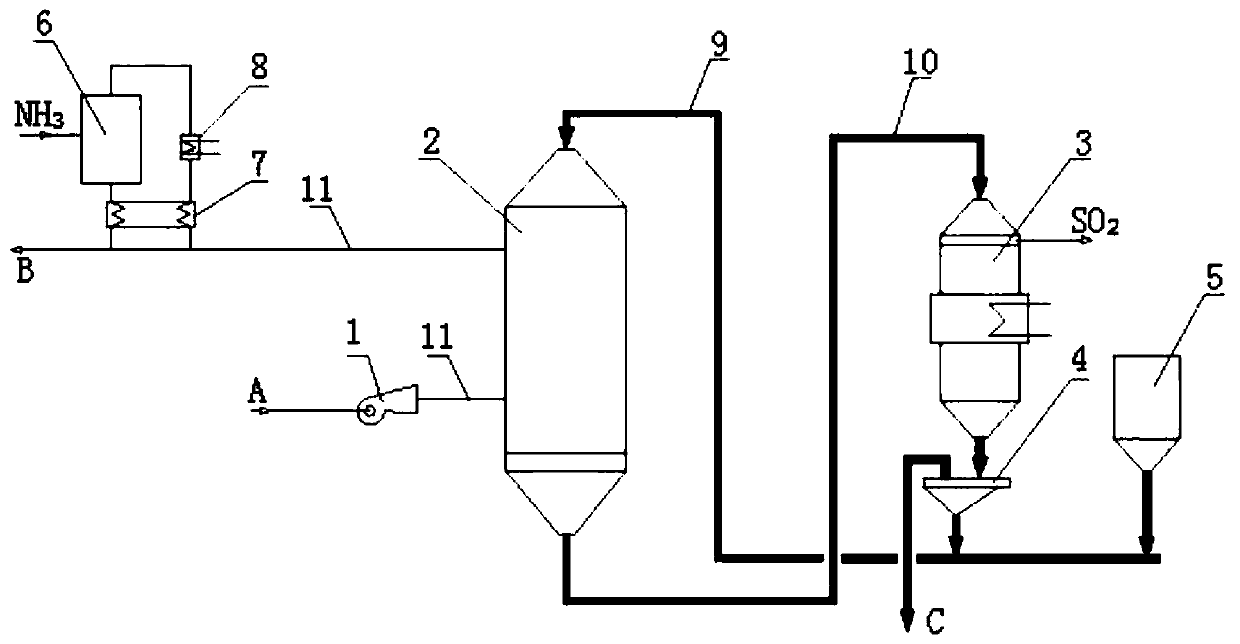

[0021] From figure 1 It can be seen that a sintering flue gas combined desulfurization and denitrification system in this embodiment includes a booster fan 1 and an active coke adsorption tower 2, and a flue gas pipeline 11 is connected between the booster fan 1 and the active coke adsorption tower 2, The input end of the activated coke adsorption tower 2 is provided with an adsorption tower feeding system 9 and an active coke silo 5, and the output end of the activated coke adsorption tower 2 is provided with a regeneration tower feeding system 10 and an active coke regeneration tower 3, and the active coke regeneration tower The bottom of 3 is provided with a screening device 4, the output end of the activated coke adsorption tower 2 is connected with the active coke regeneration tower 3 through the regeneration tower feeding system 10, and the input end of the activated coke adsorption tower 2 is connected with the active coke adsorption tower 2 through the adsorption tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com