Continuous hot grinding mechanical straw pulp preparation method

A technology of straw pulp and thermal grinding, which is applied in the field of papermaking, can solve problems such as increased cost, reduced pulp yield, and increased wastewater concentration, and achieves the effects of compact production process, less raw material consumption, and less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

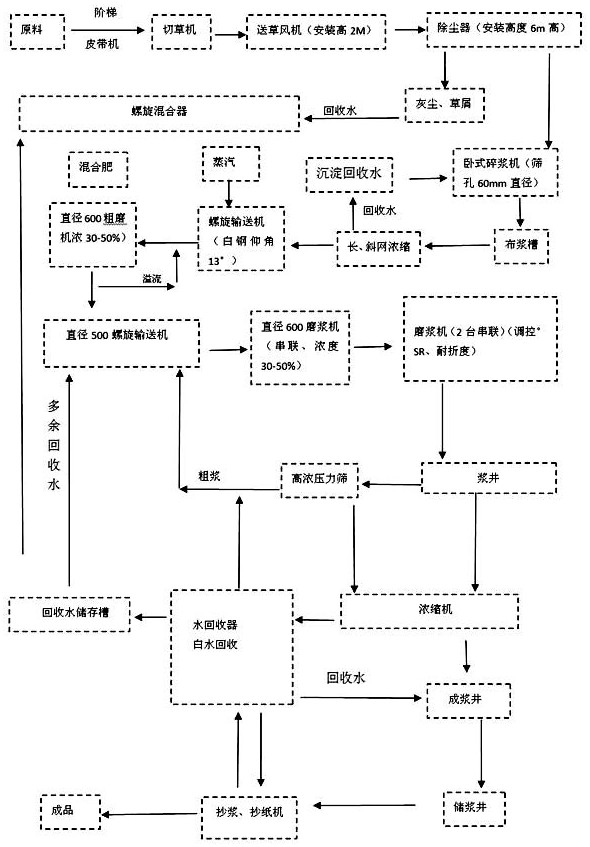

[0038] Continuous thermal grinding mechanical rice straw pulp preparation method (SMRM method):

[0039] see figure 1 , through clean production and meticulous treatment to reduce the generation of pollutants, the steps are as follows:

[0040] First, the S stage process: the main function of this stage is to wash the grass tablets with water. The straw is cut into sections, and the straw specification after cutting: 30mm-60mm (more than 70%). The raw materials are sent to the pulper for washing and concentration after dedusting, and its function is to remove dust, sand, grass blades and impurities carried by the raw materials. It is the pretreatment stage of pulping to reduce the consumption of heat and other pulping in the next stage, and to make the raw materials clean and clean. More importantly, the wastewater in this stage is easy to settle, which is beneficial to the recovery of wastewater and the recycling of sediment.

[0041] Second, the first M stage process: the...

experiment example

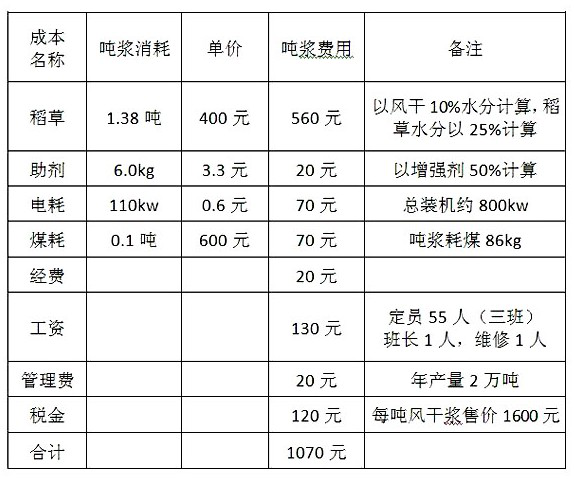

[0061] Comparison of some experimental data measured by this method:

[0062] In the practice of simulating actual production, some key technical conditions, that is, data, are the inevitable requirements and key points for SMRM (no acid and alkali) continuous heat grinding rice straw pulp technology. The main technical data and comparison of key steps are as follows:

[0063] 1. The raw materials must be washed before refining and pulping, because the waste water at this stage is easy to recycle without pollution, so that the water consumption per ton of pulp is controlled within 10 tons. The maximum does not exceed 12 tons. The water consumption at this stage is about 2 per ton of pulp.

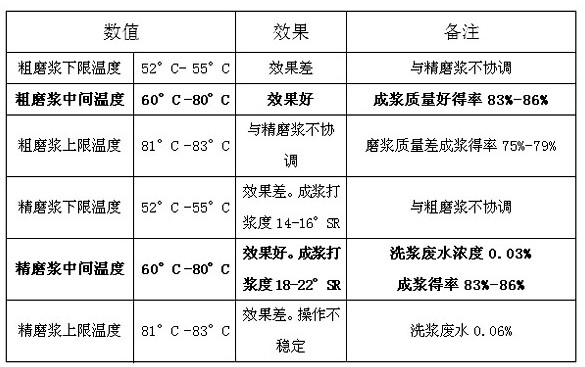

[0064] 2. Coarse refining concentration: Coarse refining is the basis of fine refining. It is a preparation for fine refining to meet the pulping requirements. It grinds the cut and washed forage into coarse fibers to facilitate heat absorption and The fibers swell. When the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com