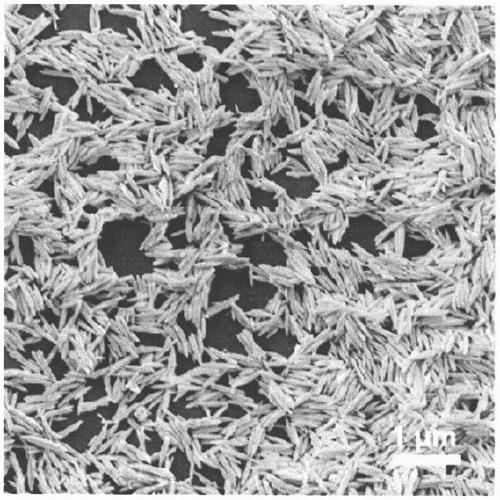

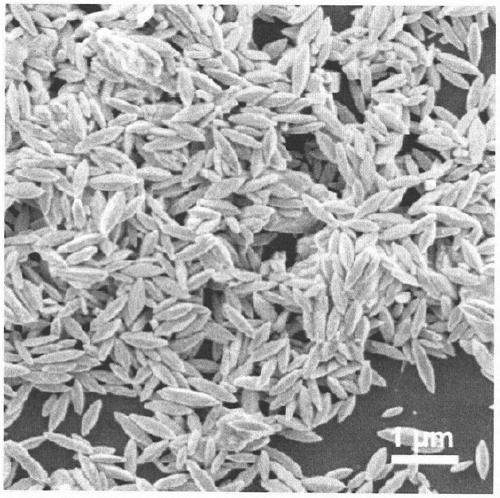

Preparation method of CsPbBr3 spindle type perovskite micro-particles with adjustable size

A technology of micron particles and perovskite, applied in chemical instruments and methods, lead compounds, inorganic chemistry, etc., can solve the problem of continuous and precise control of material shape and size, control of perovskite micron particles, and small radiation recombination efficiency coefficient and other issues, to achieve the effect of adjusting the luminous lifetime, excellent photoelectric performance, and precisely controlling the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of a size-tunable CsPbBr 3 Spindle-shaped perovskite micro-particles, the preparation method is as follows:

[0040] (1) Add 0.2g of cesium carbonate, 10ml of octadecene and 0.75ml of oleic acid into a 50ml round-bottomed flask in turn, heat up to 150°C under nitrogen protection and stir until completely dissolved, the solution is clear and transparent, and a spare solution is obtained, which is named as Solution 1;

[0041] (2) Add 0.1g of lead bromide, 10ml of octadecene, 1ml of oleylamine, and 0.2ml of 5-hexynoic acid into a 50ml round bottom flask and mix them. After mixing, stir at a constant temperature of 100°C under the protection of nitrogen until completely dissolved. At a temperature of 140°C, take 0.8ml of the spare solution 1 in step (1) and quickly inject it, stir for 5s and cool it to room temperature with an ice-water bath, put the cooled solution into a 50ml centrifuge tube, add absolute ethanol for washing, and ultrasonically Mix the solu...

Embodiment 2

[0045] Preparation of a size-tunable CsPbBr 3 Spindle-shaped perovskite micro-particles, the preparation method is as follows:

[0046] (1) Add 0.3g of cesium carbonate, 20ml of octadecene and 1.5ml of oleic acid into a 50ml round-bottomed flask in turn, heat up to 150°C under nitrogen protection and stir until completely dissolved, the solution is clear and transparent, and a spare solution is obtained, which is named as Solution 2;

[0047] (2) Add 0.2g of lead bromide, 20ml of octadecene, 3ml of oleylamine, and 0.4ml of 5-hexynoic acid into a 50ml round bottom flask and mix them. After mixing, stir at a constant temperature of 100°C under nitrogen protection until completely dissolved. At a temperature of 150°C, take 1.2ml of the spare solution 2 in step (1) and quickly inject it, stir for 5s and cool it to room temperature with an ice-water bath, put the cooled solution into a 50ml centrifuge tube, add absolute ethanol for washing, and ultrasonically Mix the solution eve...

Embodiment 3

[0051] Preparation of a size-tunable CsPbBr 3 Spindle-shaped perovskite micro-particles, the preparation method is as follows:

[0052] (1) Add 0.3g of cesium carbonate, 15ml of octadecene and 1.0ml of oleic acid into a 50ml round-bottomed flask in turn, raise the temperature to 150°C under the protection of nitrogen and stir until they are completely dissolved. The solution is clear and transparent, and a spare solution is obtained, named as Solution 3;

[0053] (2) Add 0.2g of lead bromide, 15ml of octadecene, 2ml of oleylamine, and 0.3ml of 5-hexynoic acid into a 50ml round bottom flask and mix them. After mixing, stir at a constant temperature of 110°C under nitrogen protection until completely dissolved. At a temperature of 140°C, take 1.0ml of the spare solution 3 in step (1) and quickly inject it, stir for 5s and cool it to room temperature with an ice-water bath, put the cooled solution into a 50ml centrifuge tube, add absolute ethanol for washing, and ultrasonically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com