Chlorination liquid continuous neutralization method in sucralose production

A technology of sucralose and chlorinated solution, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the limitation of continuous industrial production of sucralose, which is not conducive to the amplification, stability and neutralization of sucralose Insufficient effect and other problems, to achieve the effect of stable control of production process indicators, shortened reaction time, and small fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

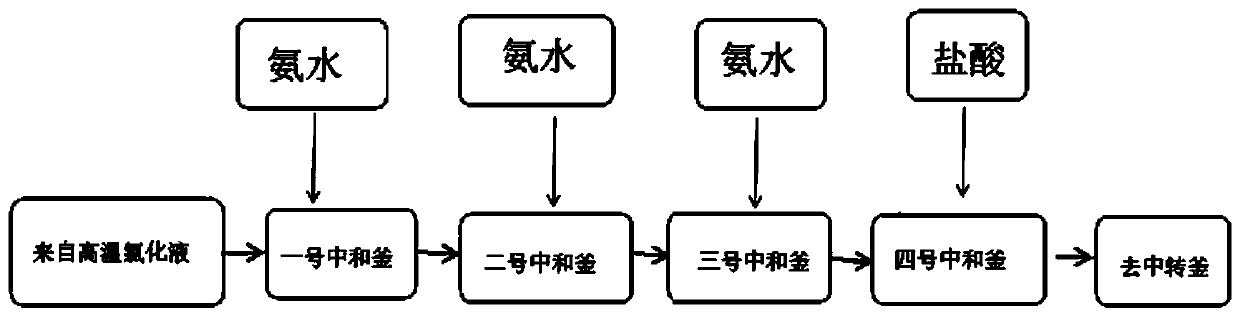

[0024] A kind of chlorinated liquid continuous neutralization method in the production of sucralose provided by the invention, such as figure 1 shown, including the following steps:

[0025] a. Start the ammonia water pump, start the chlorinated liquid pump, and start the stirring of the 1# neutralization tank. After cooling down from the chlorinated liquid, enter the 1# neutralization tank continuously at a flow rate of 5±0.5m³ / h, and continuously add it with a certain flow rate. The ammonia water is circulated and reacted in the 1# neutralization tank, and the flow of ammonia water is automatically adjusted and controlled according to the pH value. The pH value of the reaction liquid is finally controlled at 6-7, and the temperature of the whole process is 15±1°C. The raw material liquid and the reaction liquid are continuous Pump in continuous pump out.

[0026] b. The chlorinated liquid after the reaction in the 1# neutralization tank enters the 2# neutralization tank at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com