Vulcanized rubber reclaimed rubber and preparation method thereof

A technology for vulcanized rubber and reclaimed rubber, applied in the field of rubber, can solve the problems of high cost of rejuvenating agent, unsuitable for industrialization, large dosage, etc., and achieve the effects of low cost, good de-crosslinking selectivity and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Vulcanized natural rubber preparation:

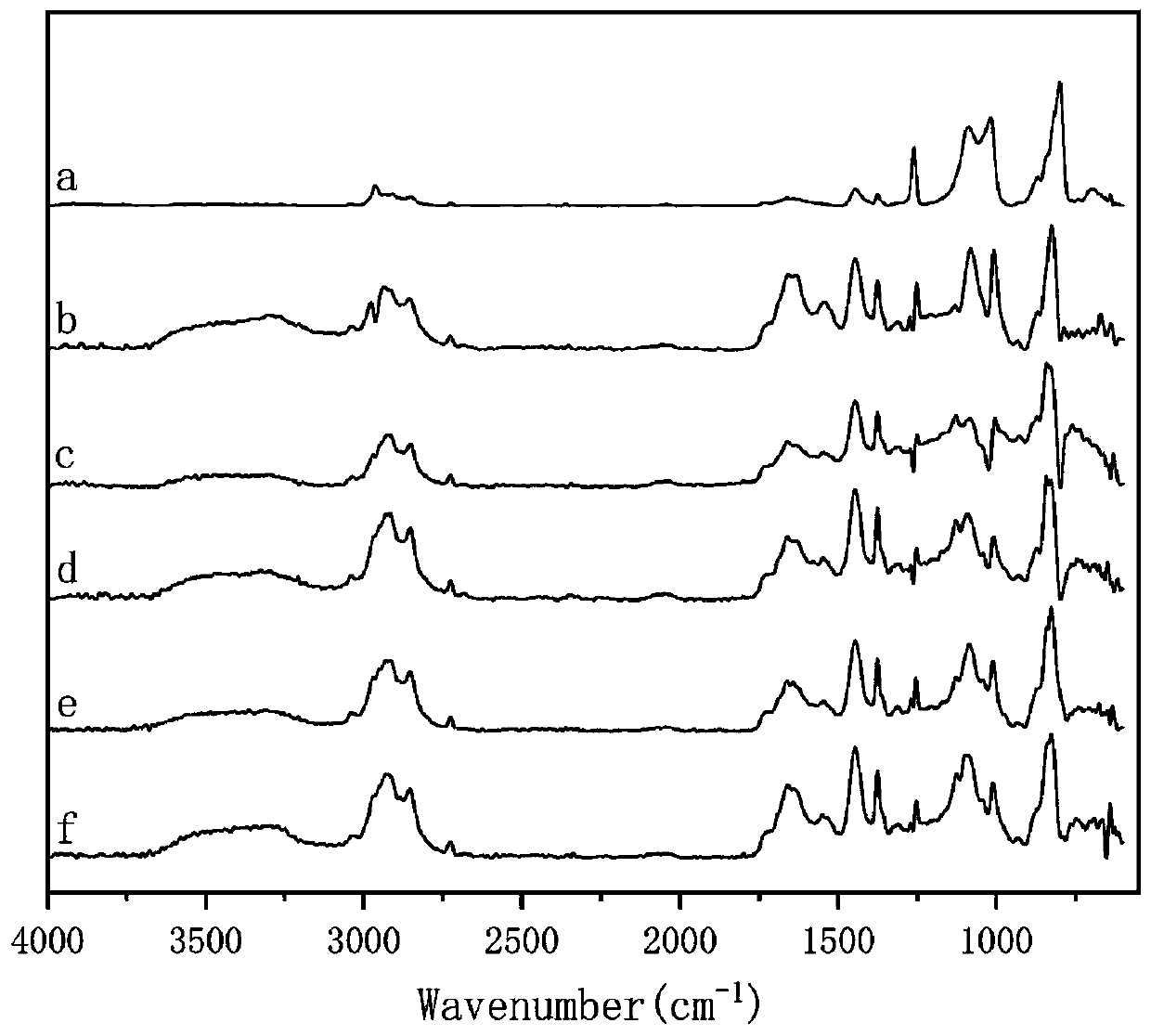

[0049] The preparation method of the vulcanized natural rubber sample that adopts in the embodiment is as follows: raw material (100 parts of natural rubber, 5 parts of zinc oxides, 2 parts of stearic acid, 0.6 part of promotor NS, 2.5 parts of sulfur) are mixed in open mill After refining, the mixed rubber sheet was vulcanized in a flat vulcanizer at 143° C. for 13 minutes to obtain the vulcanized natural rubber sample required by the embodiment.

[0050] Vulcanized rubber reclaimed rubber preparation:

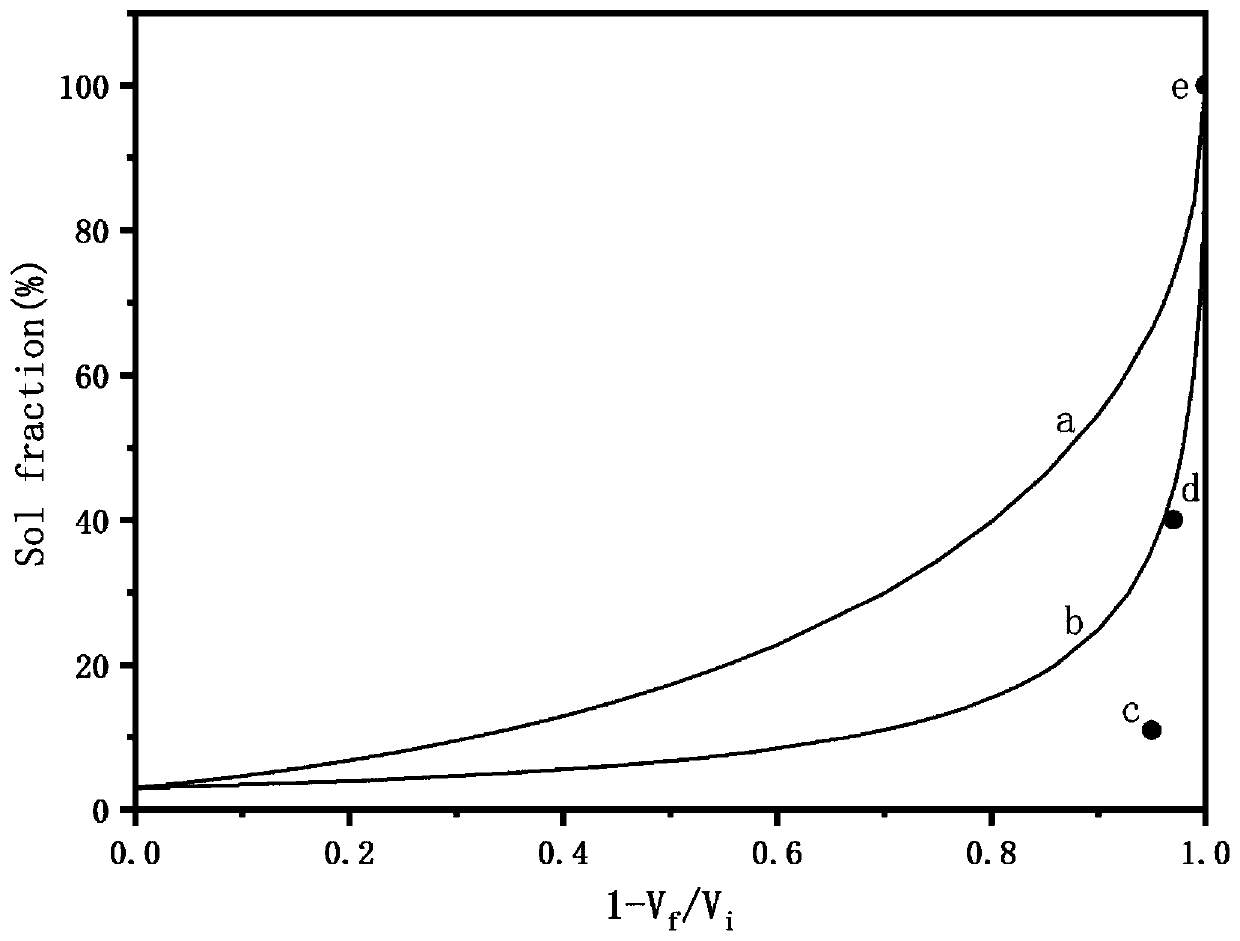

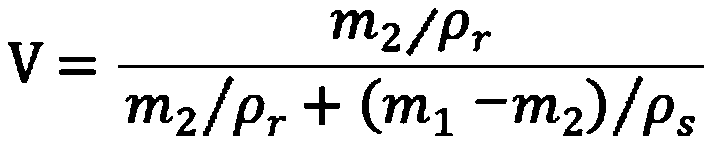

[0051] Take 1.5g of vulcanized natural rubber sample, place it in 0.15L of xylene to fully swell, add 0.045g of regenerant 3,6-dioxa-1,8-octanedithiol, control the system temperature at 120°C, and keep it warm After 8 hours, add 0.15L of methanol for flocculation, take out the flocs and dry them at 50°C for 24 hours to obtain a product with a decrosslinking degree greater than 95% and a crosslinking density less than 1*10 -5 m...

Embodiment 2

[0052] Embodiment 2: Preparation of vulcanized rubber reclaimed rubber

[0053] Using 1.5g of the vulcanized natural rubber sample prepared in Example 1, after being fully swollen in 0.15L xylene, add 0.09g regenerant 3,6-dioxa-1,8-octanedithiol, control The temperature of the system is 120°C, keep it warm for 8 hours, add 0.15L of methanol for flocculation, take out the flocs and dry them at 50°C for 24 hours, the obtained product has a decrosslinking degree of more than 97% and a crosslinking density of less than 9*10 -6 mol / cm 3 , Molecular weight greater than 90000.

Embodiment 3

[0054] Embodiment 3: Preparation of vulcanized rubber reclaimed rubber

[0055] Using 1.5g of the vulcanized natural rubber sample prepared in Example 1, after being fully swelled in 0.15L xylene, add 0.15g regenerant 3,6-dioxa-1,8-octanedithiol, control The temperature of the system is 120°C, keep it warm for 10 hours, add 0.15L of methanol for flocculation, take out the flocs and dry them at 50°C for 24 hours to obtain a product with a degree of decrosslinking of 100%, a degree of decrosslinking of 100%, and a crosslinking density of less than 3*10 -6 mol / cm 3 , molecular weight greater than 100,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com