Multi-surface cleaning agent containing tea saponin modified surfactant

A technology of surfactant and tea saponin, applied in the direction of surface active detergent composition, polymer surface active compound, detergent compounding agent, etc., can solve the problems of difficult rinsing, strong foaming performance, medium and high detergency ability , to achieve the effect of easy rinsing, excellent foam performance and strong detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

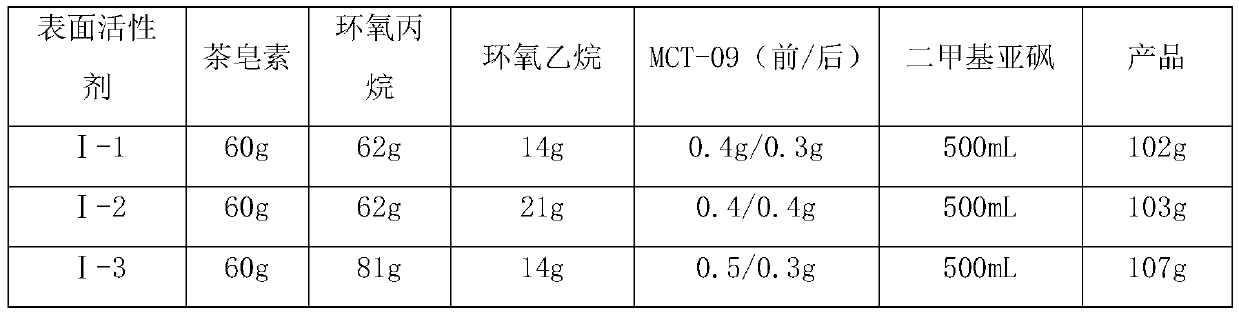

[0032] Synthesis of Tea Saponin PO / EO Block Polyether Modified Surfactant Ⅰ:

[0033] Add tea saponin and dimethyl sulfoxide to the autoclave, add the catalyst MCT-09, replace the air in the reactor with nitrogen, raise the temperature to 150 degrees Celsius, vacuumize, slowly feed propylene oxide, and control the The pressure is 3-4 standard atmospheres, and the reaction is stirred for 4 hours. When the pressure of the reactor drops to normal pressure, add MCT-09, slowly feed ethylene oxide, control the pressure in the kettle to 3-4 standard atmospheres, and continue to heat up After reaching 150 degrees Celsius, react for 4 hours. After the temperature of the kettle drops to normal pressure, cool to room temperature, vacuumize, replace the gas in the kettle with nitrogen, filter the reaction solution to remove the catalyst, concentrate the reaction solution and add it to petroleum ether to precipitate a solid. , and the solid obtained after filtering is dried to obtain a tea...

Embodiment 2

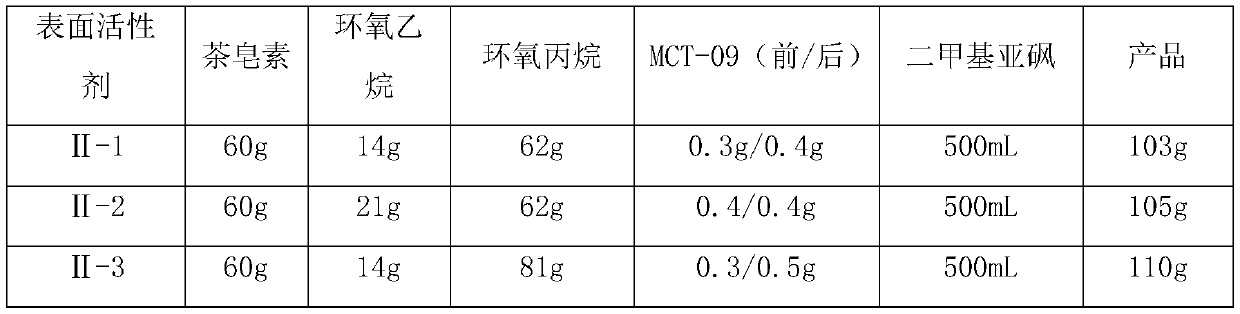

[0038] Synthesis of Tea Saponin EO / PO Block Polyether Modified Surfactant Ⅱ:

[0039] Add tea saponin and dimethyl sulfoxide to the autoclave, add the catalyst MCT-09, replace the air in the reactor with nitrogen, raise the temperature to 140 degrees Celsius, vacuumize, slowly feed ethylene oxide, and control the reactor The internal force is 3-4 standard atmospheres, and the reaction is stirred for 4 hours. When the pressure of the reactor drops to normal pressure, add MCT-09, slowly feed propylene oxide, control the pressure in the kettle to 3-4 standard atmospheres, and continue to heat up to After reacting at 140 degrees Celsius for 4 hours, after the temperature of the kettle dropped to normal pressure, cool to room temperature, vacuumize, replace the gas in the kettle with nitrogen, filter the reaction solution to remove the catalyst, concentrate the reaction solution and add it to petroleum ether to precipitate a solid. The solid obtained after filtering is dried to obt...

Embodiment 3

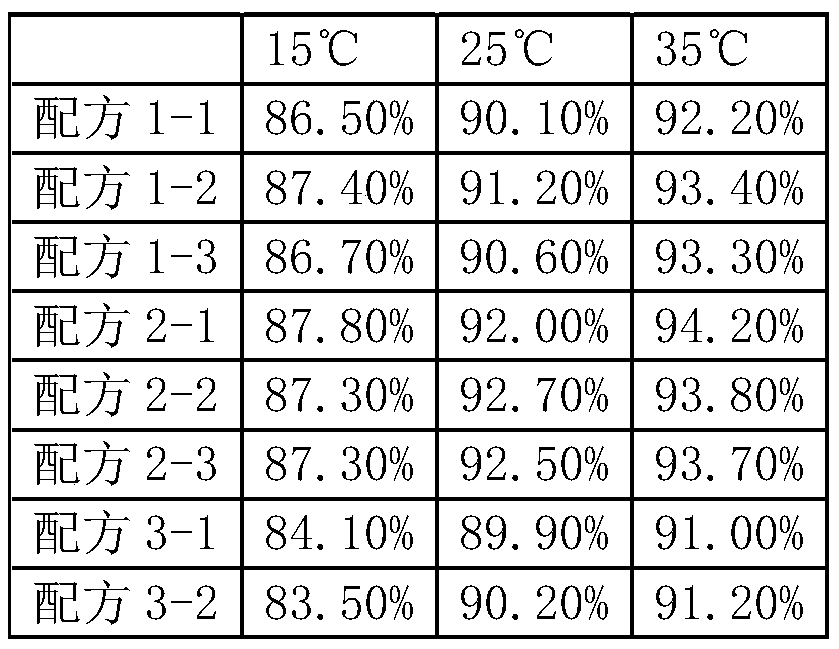

[0044] Formula 1: In parts by mass, 10 parts of tea saponin modified surfactant (Ⅰ-1), 4 parts of fatty alcohol polyoxyethylene ether butyl-capped, 2 parts of alkyl glycoside APG 08, 7 parts of sodium citrate , 5 parts of sodium gluconate, 0.2 parts of sodium bicarbonate, 12 parts of ethylene glycol monobutyl ether, 0.1 part of preservative, and 100 parts of water. The preservative is methylisothiazolinone.

[0045] In formula 2-6, in addition to replacing the tea saponin modified surfactant (I-1) in formula 1 with I-2, I-3, II-1, II-2, and II-3, other components constant.

[0046] Formula 7: Except that the tea saponin-modified surfactant (I-1) in formula 1 was replaced with tea saponin, other components remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| detergency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com