Automobile pull-off block machining process

A processing technology and a technology for pulling off blocks, which are applied in metal processing equipment, manufacturing tools, mechanical cleaning, etc., can solve the problems of affecting the quality of pulling off blocks, easy residues of aluminum water, and difficulty in salvage and cleaning, so as to reduce scum or the possibility of slag inclusions, the effect of improving the molding quality and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

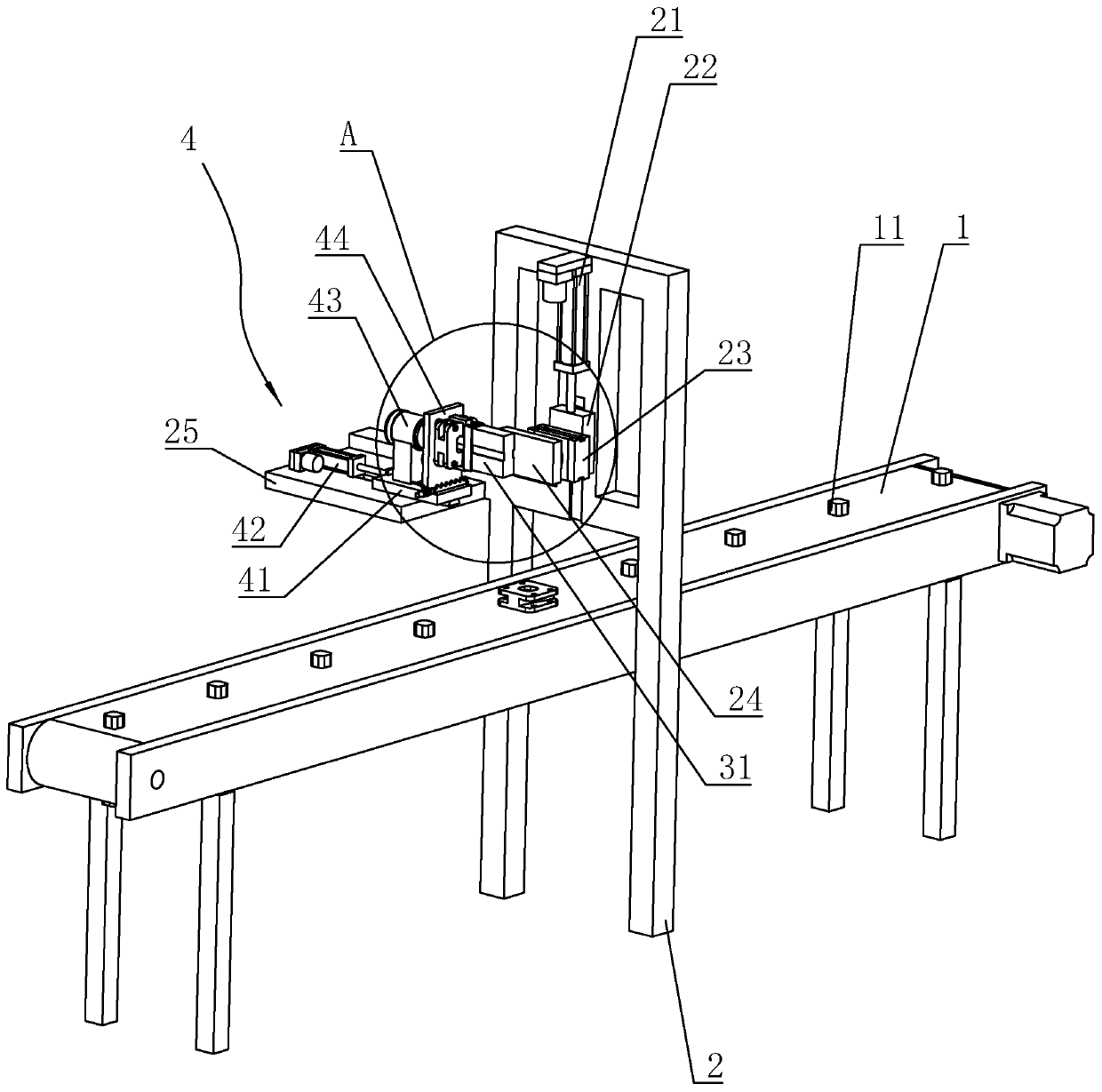

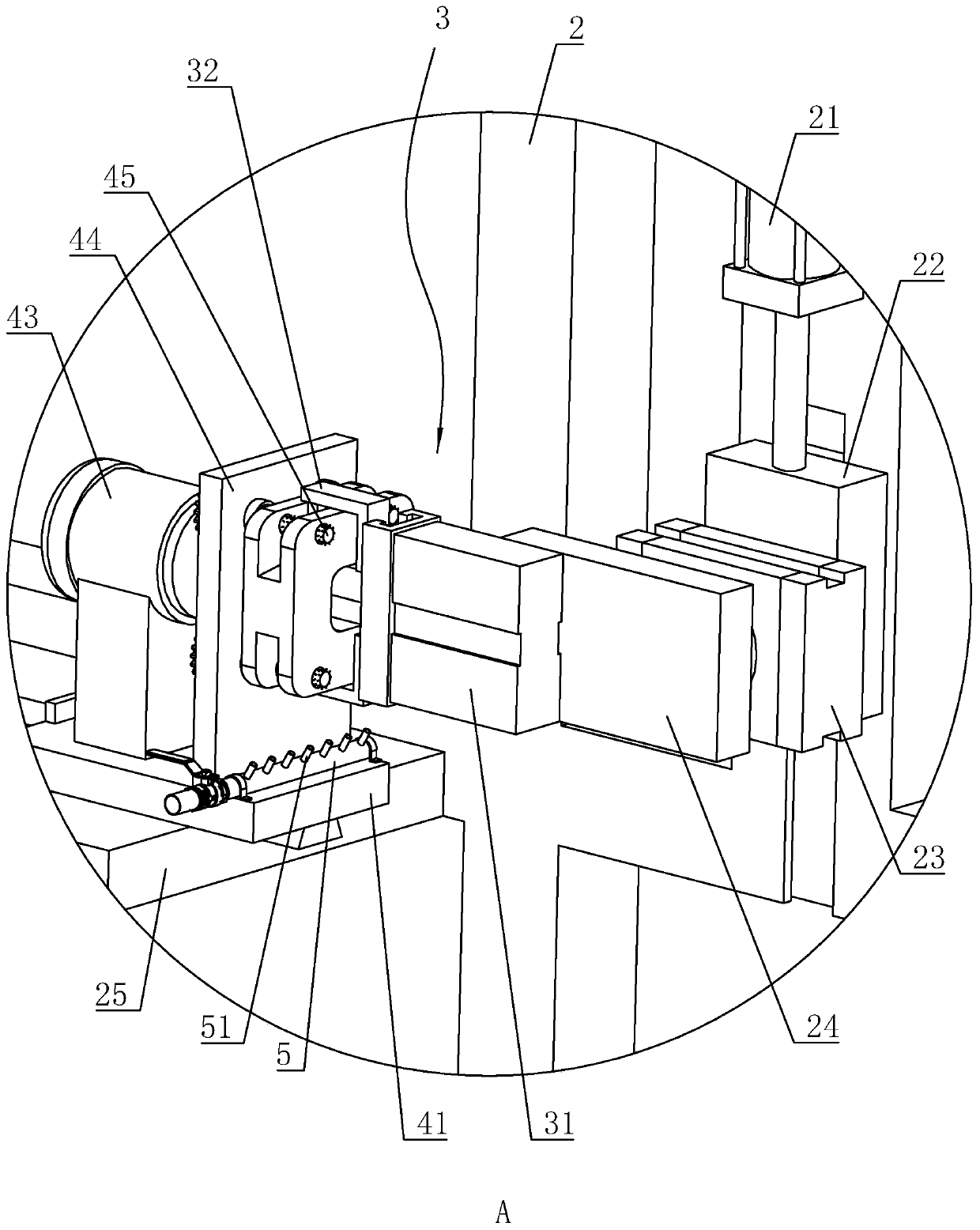

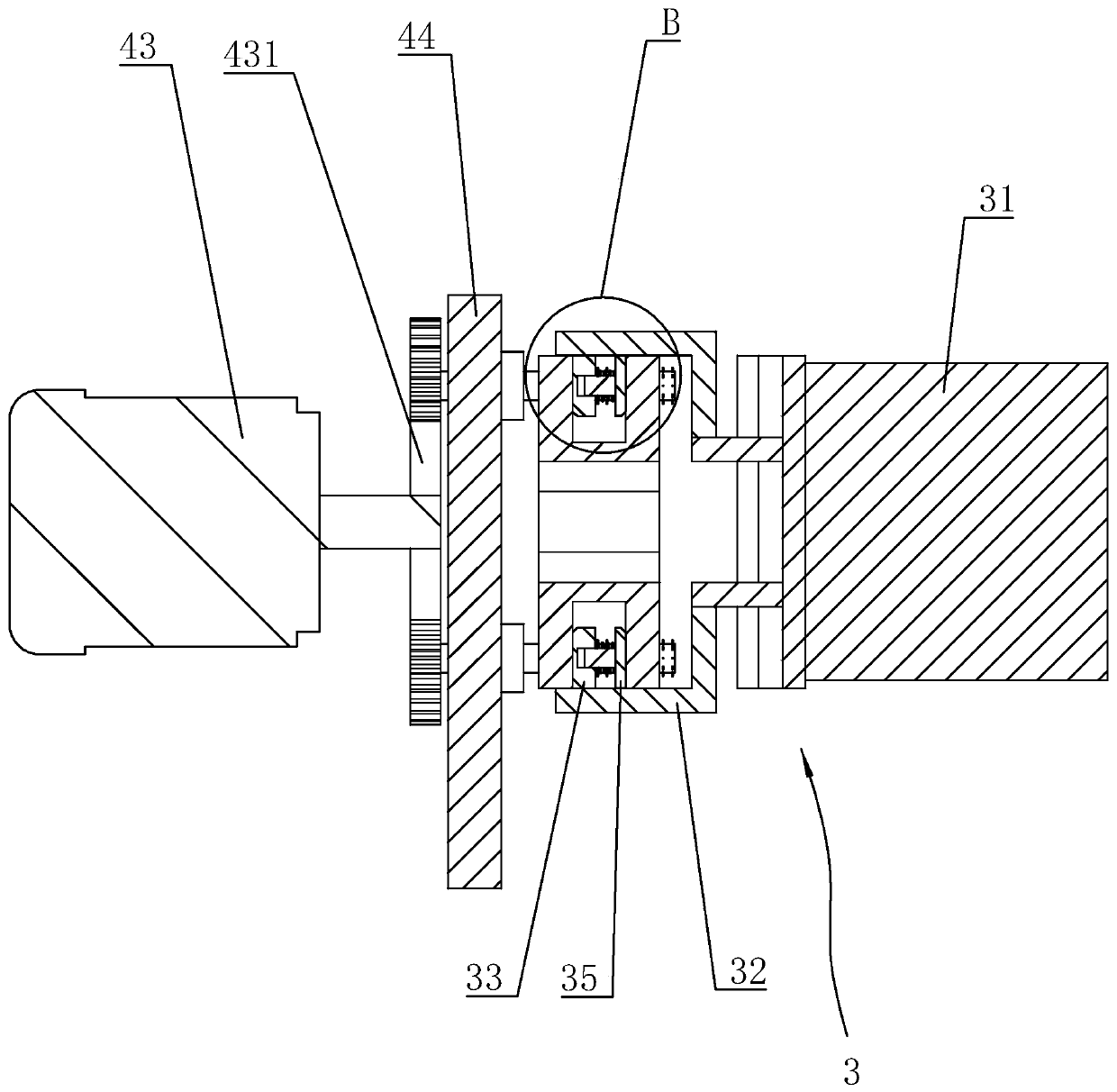

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] This invention discloses a process for processing automobile pull-off blocks, including the following steps: A1, raw material preparation, equipment debugging; using a trolley or a forklift to transport aluminum alloy blocks or waste castings, gates, risers, etc. of the same material back into the furnace Go to the melting furnace, check the smelting, sampling and other tools and keep the tools dry, the melting furnace staff wear protective clothing; check whether the switches of the die-casting machine are functioning normally and whether there is any abnormal sound in the machine, and then preheat the mold with oil.

[0039] A2. Put the aluminum alloy block and returned charge into the melting furnace, heat and stir, so that the aluminum alloy block and returned charge are fully dissolved into a liquid state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com