High-performance thermal barrier coating for heavy duty gas turbine blade, and multi-process combination preparation method thereof

A technology of gas turbine blades and thermal barrier coatings, which is applied in the direction of metal material coating technology, coating, fusion spraying, etc., can solve the problems of affecting the service life of blades and low bonding strength, so as to improve the service life and increase the contact area , Improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

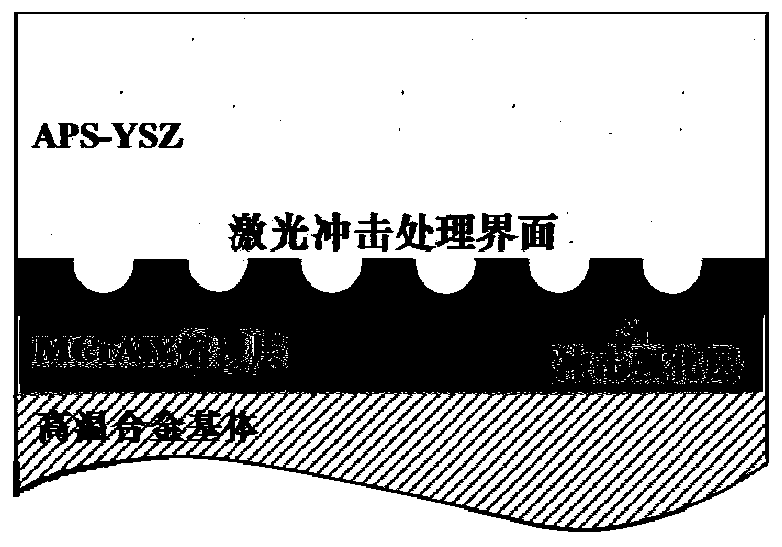

[0035] The thermal barrier coating is prepared by using the superalloy base material for gas turbine blades as the carrier. The process flow is: sample inspection→grinding and polishing→ultrasonic cleaning→laser cladding technology to prepare MCrAlY bonding layer→machining→grinding and polishing→ultrasonic Cleaning→Large area laser shock strengthening treatment→Grinding and polishing→Selective laser shock micro-modeling treatment→Sandblasting→Preparation of YSZ ceramic layer by atmospheric plasma spraying→Inspection.

[0036] The coating preparation steps are:

[0037] (1) Grinding and polishing the blade base material, followed by ultrasonic cleaning;

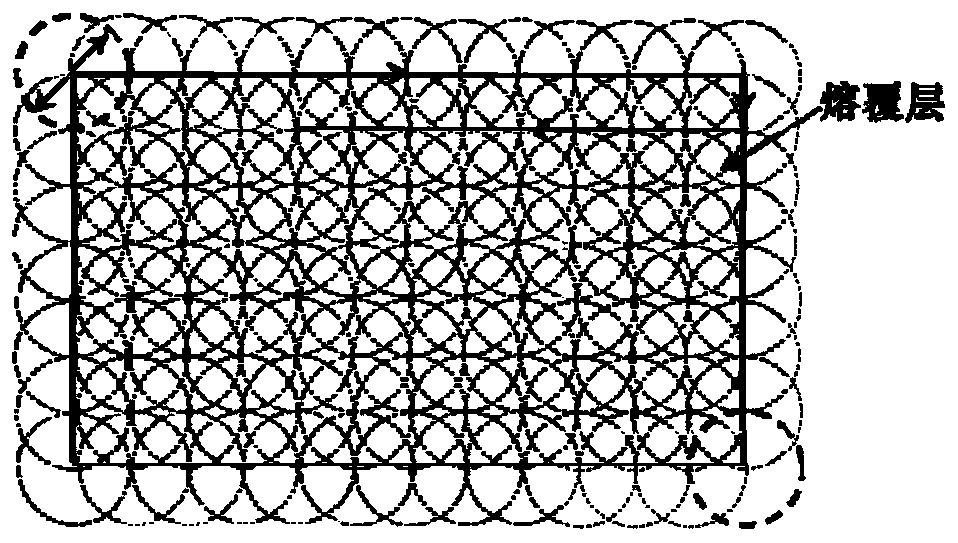

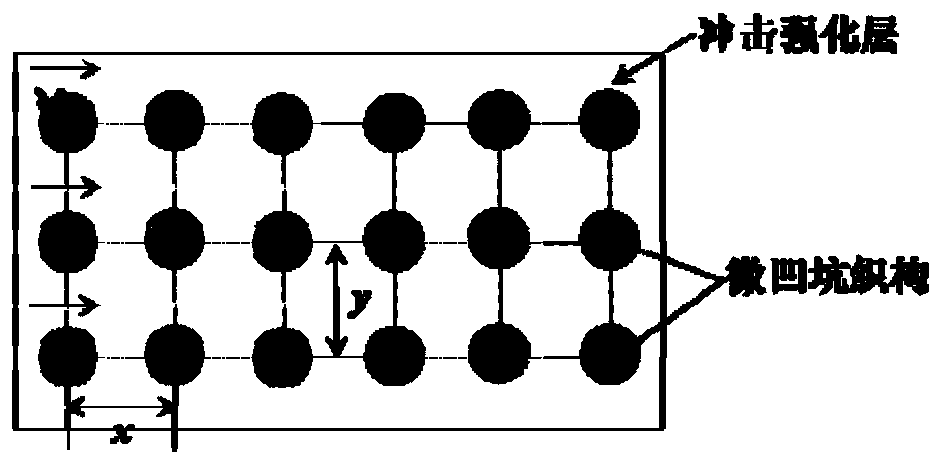

[0038] (2) The MCrAlY (M=Ni) bonding layer is prepared by laser cladding technology. The coating powder is about 200 meshes. The laser cladding process parameters are selected as laser power 1.8Kw, scanning speed 600mm / min, and powder feeding rate 1.2 r / min, the spot diameter is 3mm, the overlap rate is 50%, and the thickness of th...

Embodiment 2

[0047] The preparation of TBCs was carried out according to the steps described in Example 1, the difference is:

[0048] The coating preparation steps are:

[0049] (1) Grinding and polishing the base material, followed by ultrasonic cleaning;

[0050] (2) The MCrAlY (M=Ni) bonding layer is prepared by laser cladding technology. The coating powder is about 200 meshes. The laser cladding process parameters are selected as laser power 2.0Kw, scanning speed 800 mm / min, and powder feeding rate 1.5r / min, the spot diameter is 3mm, the overlap rate is 50%, and the thickness of the cladding layer is 1000μm;

[0051] (3) Machine processing to remove the oxide scale on the surface of the cladding layer, and the cladding layer is polished, polished and ultrasonically cleaned to obtain the best surface condition to be impacted;

[0052] (4) Using nano lasers to perform large-area laser shock strengthening treatment on the surface of the MCrAlY cladding layer, choose aluminum foil as the absorpti...

Embodiment 3

[0059] The thermal barrier coating is prepared by using the superalloy base material for gas turbine blades as the carrier. The process flow is: sample inspection→grinding and polishing→ultrasonic cleaning→laser cladding technology to prepare MCrAlY bonding layer→machining→grinding and polishing→ultrasonic Cleaning→Large area laser shock strengthening treatment→Grinding and polishing→Selective laser shock micro-modeling treatment→Sandblasting→Preparation of YSZ ceramic layer by atmospheric plasma spraying→Inspection.

[0060] The coating preparation steps are:

[0061] (1) Grinding and polishing the blade base material, followed by ultrasonic cleaning;

[0062] (2) Using laser cladding technology to prepare MCrAlY (M=Ni) bonding layer, the coating powder is about 300 meshes, and the laser cladding process parameters are selected as laser power 2.2Kw, scanning speed 800mm / min, and powder feeding rate 1.4r / min, the spot diameter is 4mm, the overlap rate is 30%, and the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com