A kind of preparation method of natural color furniture protective paper

A technology for protecting paper and furniture, which is applied in the field of papermaking, can solve the problems of high cost and cumbersome preparation process, and achieve the effects of high smoothness, increased wet strength and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

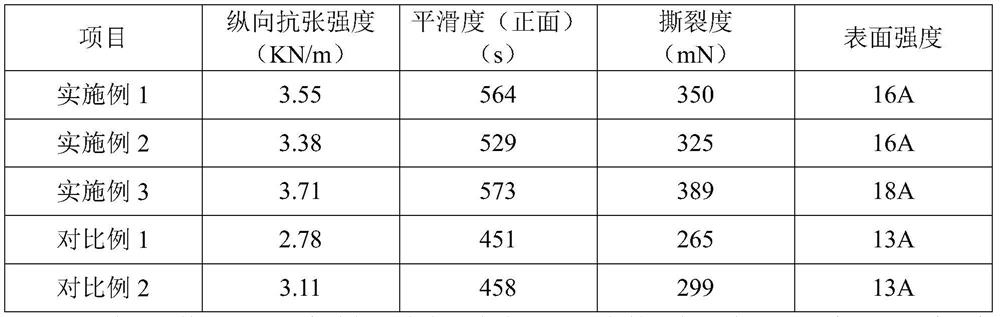

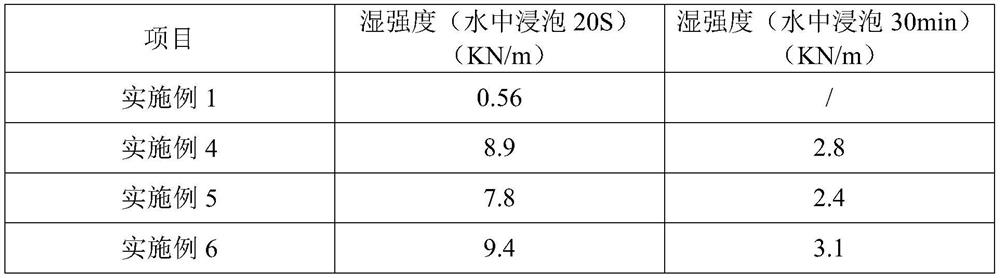

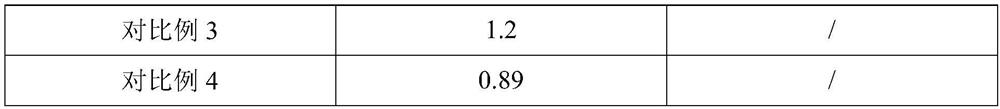

Examples

Embodiment 1

[0038] Embodiment 1: a kind of preparation method of natural color furniture protection paper, comprises following preparation method:

[0039] (1) beating: the unbleached soft wood pulp is subjected to beating treatment, the degree of pulp is 35°SR, and the wet weight is 10.0g;

[0040] (2) Addition of additives: Add degassing agent, cationic modified starch, cationic rosin gum, and aluminum sulfate to the wood pulp after beating and mix evenly. The amount of degassing agent per ton of paper is 0.7kg, and cationic modified starch The consumption per ton of paper is 7kg, the consumption per ton of paper of cationic rosin glue is 10kg, and the consumption per ton of paper of described aluminum sulfate is 17kg;

[0041] (3) Filler addition: add polyhydroxypropyl methacrylate-coated titanium dioxide particles and mix evenly, and the amount per ton of paper is 100kg;

[0042] (4) pressing and drying treatment;

[0043] (5) Calendering treatment: calendering at 100°C;

[0044] (6)...

Embodiment 2

[0048] Embodiment 2: a kind of preparation method of natural color furniture protection paper, comprises following preparation method:

[0049] (1) beating: the unbleached soft wood pulp is subjected to beating treatment, the degree of pulp is 30°SR, and the wet weight is 9.0g;

[0050] (2) Addition of additives: Add degassing agent, cationic modified starch, cationic rosin gum, and aluminum sulfate to the wood pulp after beating and mix evenly. The consumption per ton of paper is 5kg, the consumption per ton of paper of cationic rosin glue is 15kg, and the consumption per ton of paper of described aluminum sulfate is 15kg;

[0051] (3) Filler addition: add polyhydroxypropyl methacrylate-coated titanium dioxide particles and mix evenly, and the amount per ton of paper is 80kg;

[0052] (4) pressing and drying treatment;

[0053] (5) Calendering treatment: calendering at 90°C;

[0054] (6) Slitting and packaging;

[0055] The preparation steps of titanium dioxide particles ...

Embodiment 3

[0058] Embodiment 3: a kind of preparation method of natural color furniture protection paper, comprises following preparation method:

[0059] (1) beating: the unbleached soft wood pulp is subjected to beating treatment, the degree of pulp is 40°SR, and the wet weight is 11.0g;

[0060] (2) Addition of additives: Add degassing agent, cationic modified starch, cationic rosin gum, and aluminum sulfate to the wood pulp after beating and mix evenly. The consumption per ton of paper is 10kg, the consumption per ton of paper of cationic rosin glue is 25kg, and the consumption per ton of paper of described aluminum sulfate is 20kg;

[0061] (3) Filler addition: adding titanium dioxide particles coated with polyhydroxypropyl methacrylate and mixing, the amount of paper per ton is 120kg;

[0062] (4) pressing and drying treatment;

[0063] (5) Calendering treatment: calendering at 120°C;

[0064] (6) Slitting and packaging;

[0065] The preparation steps of titanium dioxide partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com