Solar cell conductive paste, frit and solar cell

A technology of solar cells and conductive pastes, applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve problems such as poor wettability, long ball milling time, large particle size, etc., and achieve normal EL detection , High battery efficiency and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

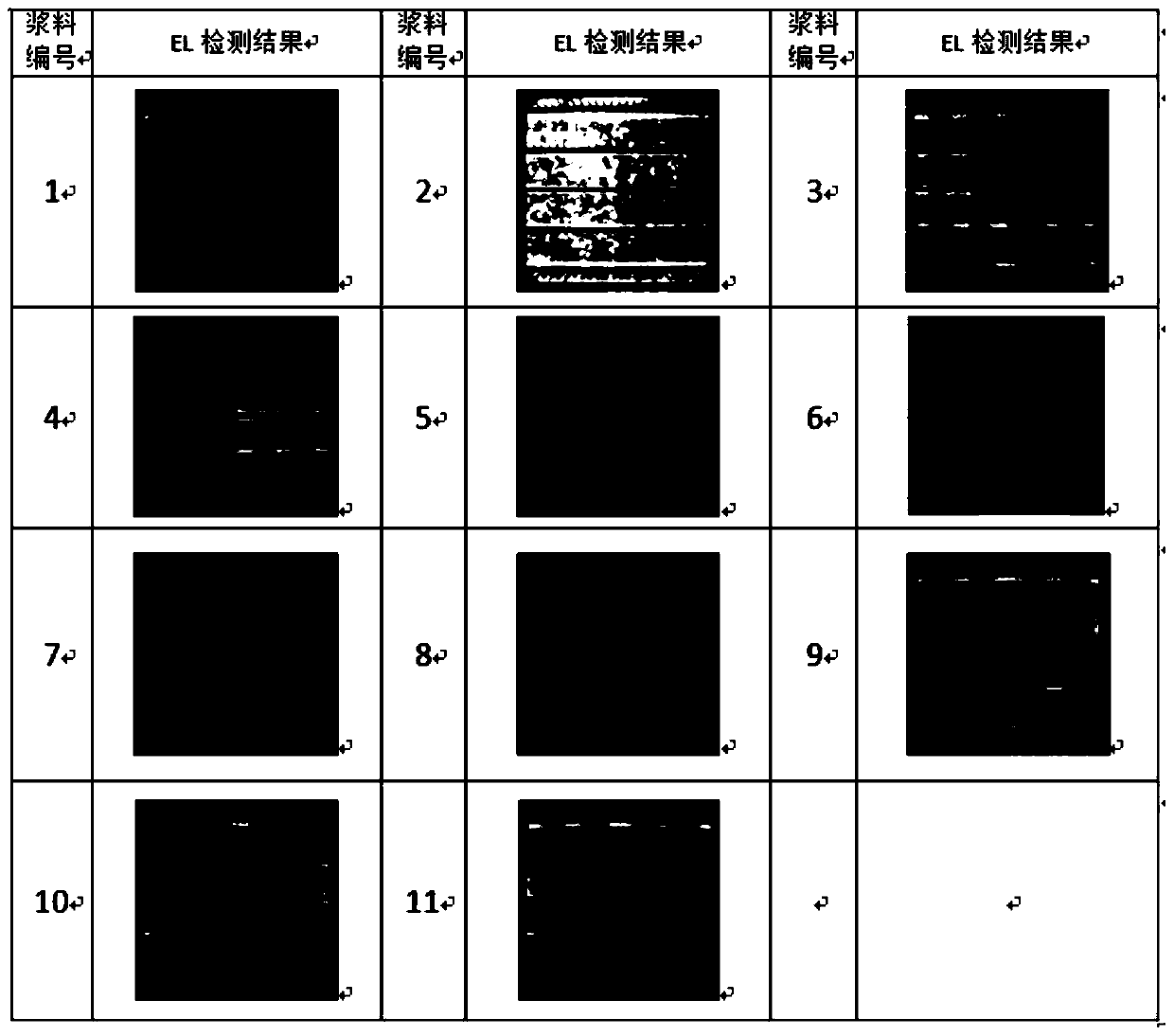

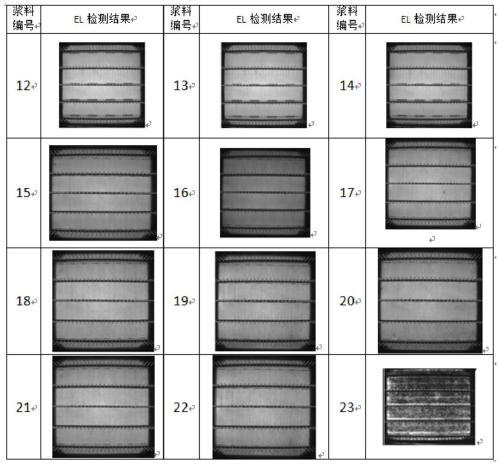

Examples

Embodiment 1

[0051] 【Sample making】

[0052] (1) Making tellurium-based glass:

[0053] Prepare TeO 2 、 Bi 2 o 3 、WO 3 , ZnO, Al 2 o 3 , LiO 2 According to the ratio shown in Table 1, these glass raw materials were weighed and prepared, and finally small sample glasses A-1 to A-7 were made. Among them, A-1 to A-3 and A-8 are only comparative examples, and A-4 to A-7 are tellurium-based glasses containing no lead, zinc and silicon in this example, and lithium bismuth tellurium as an essential component.

[0054] Table 1 Glass-forming situation (wt%) of sample glass of different formulations

[0055] TeO 2

Bi 2 o 3

WO 3

ZnO SiO 2

Al 2 o 3

Li 2 o

Glass formation A-1 50 26 7 4 3 0.2 9.8 Phase A-2 70 10 9 2 1.5 0.2 7.3 Phase A-3 60 25 9 / 1.5 0.2 4.3 partial phase separation A-4 65 18.8 9 / / 0.2 7 good A-5 55 20 15.8 / / 0.2 9 good A-6 50 35.8 9 / / 0.2 5 ...

Embodiment 2

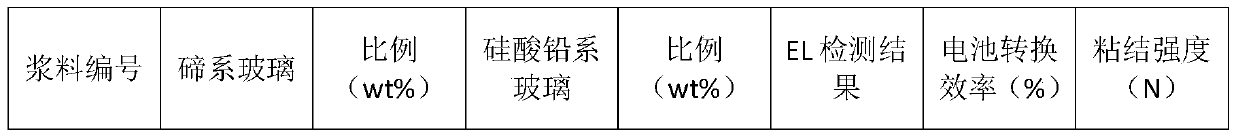

[0075] 【Sample evaluation】

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com