Permanent magnet motor rotor

A permanent magnet motor and rotor technology, applied in asynchronous induction motors, magnetic circuit rotating parts, magnetic circuits, etc., can solve the problems of complicated structure, decreased magnetic performance of permanent magnets, increased weight, etc., to achieve lightweight design, The effect of reducing the risk of demagnetization and improving the efficiency of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

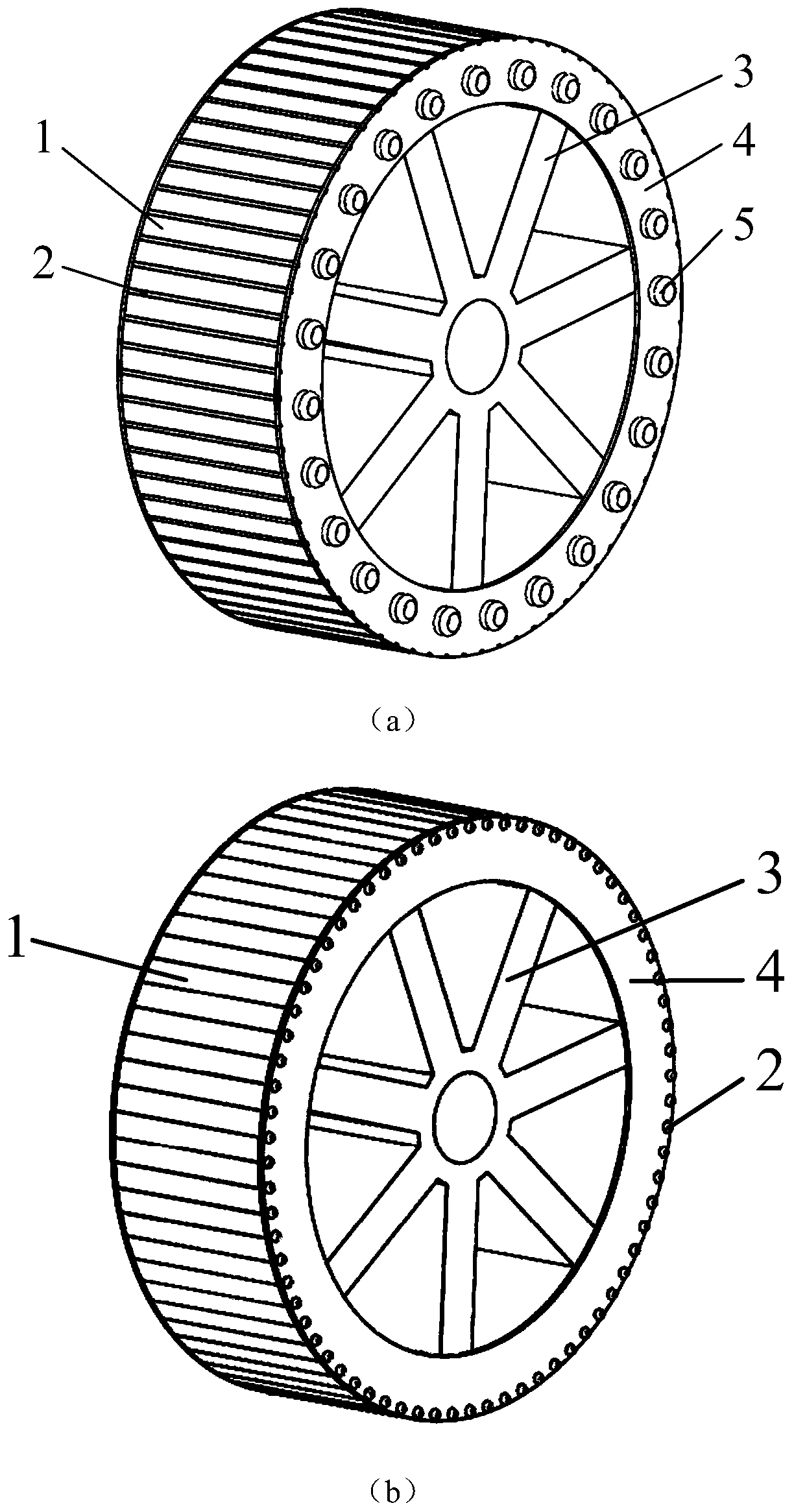

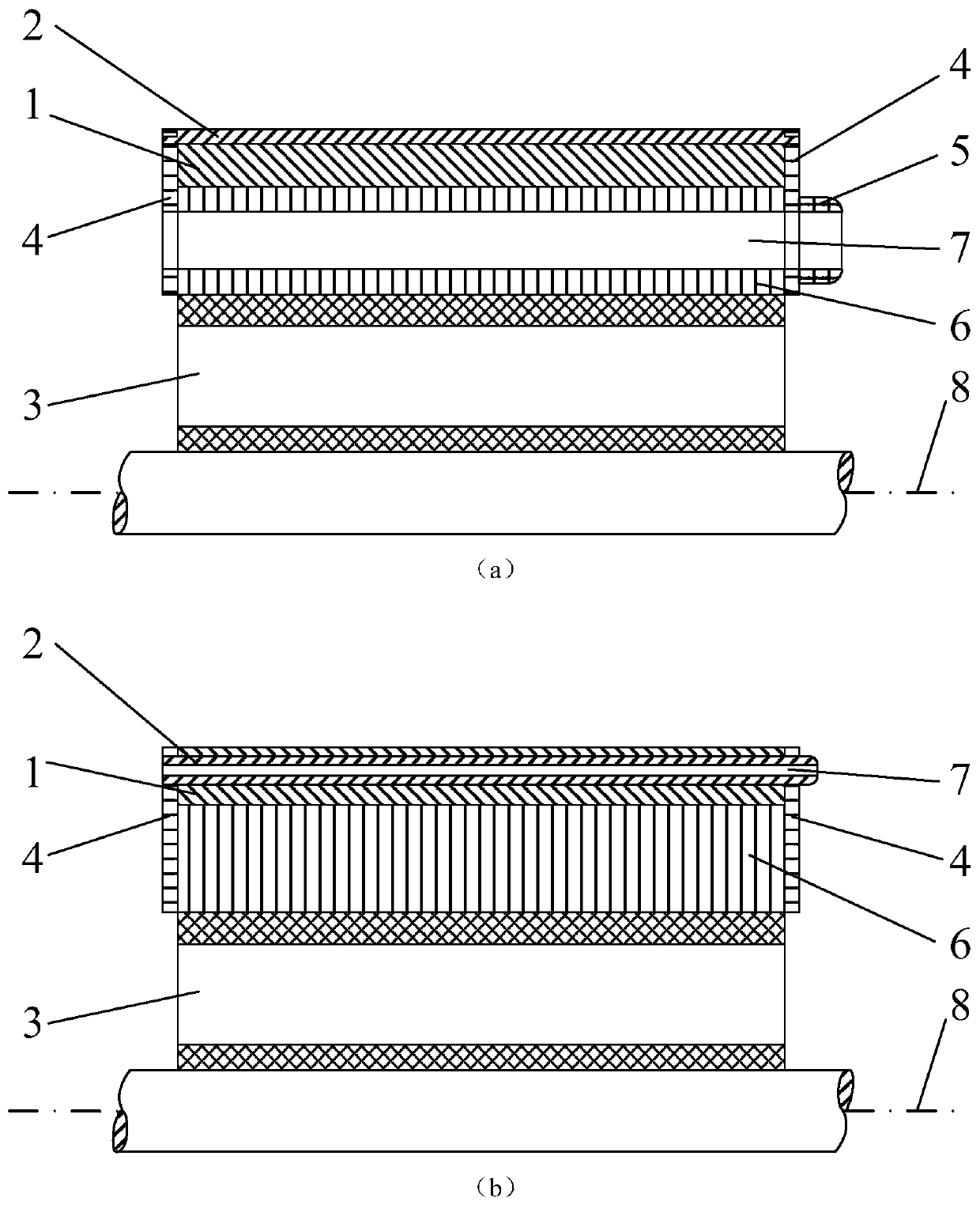

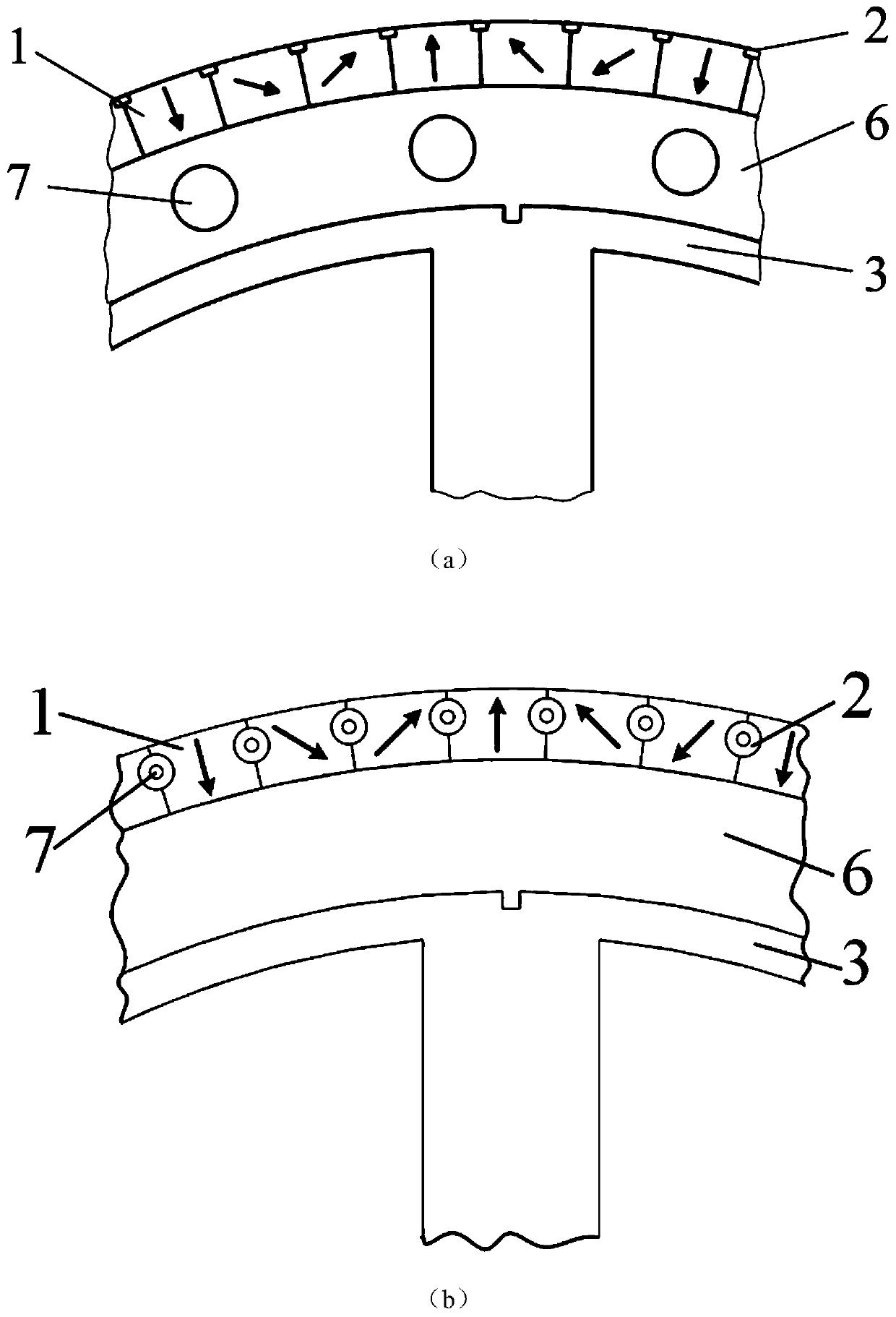

[0028] The invention provides a lightweight and low-loss permanent magnet motor rotor, which includes a permanent magnet, a rotor yoke, a rotor bracket, a damping winding and an air nozzle; the damping winding is a squirrel-cage damping winding, which is installed on the surface of the rotor The permanent magnet is installed on the rotor yoke, the rotor is provided with an axial air channel along the axial direction, the two ends of the rotor yoke are provided with end plates, and the end plate at one end is provided with an air nozzle.

[0029] Further, the permanent magnets are surface-mounted on the rotor yoke. If the permanent magnets are placed in a Halbach array, the rotor yoke is eliminated, and the permanent magnets are directly installed on the rotor bracket.

[0030] Further, the squirrel-cage damping winding is composed of a damping bar a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com