Preparation method of laser film with character holography

A laser film and holographic technology, applied in chemical instruments and methods, flexible and slender components, flexible coverings, etc., can solve the problems of complex nickel plate production process, affecting production efficiency, strict quality requirements, etc., and achieve good separation capacity, improved production efficiency, and low membrane pressure temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

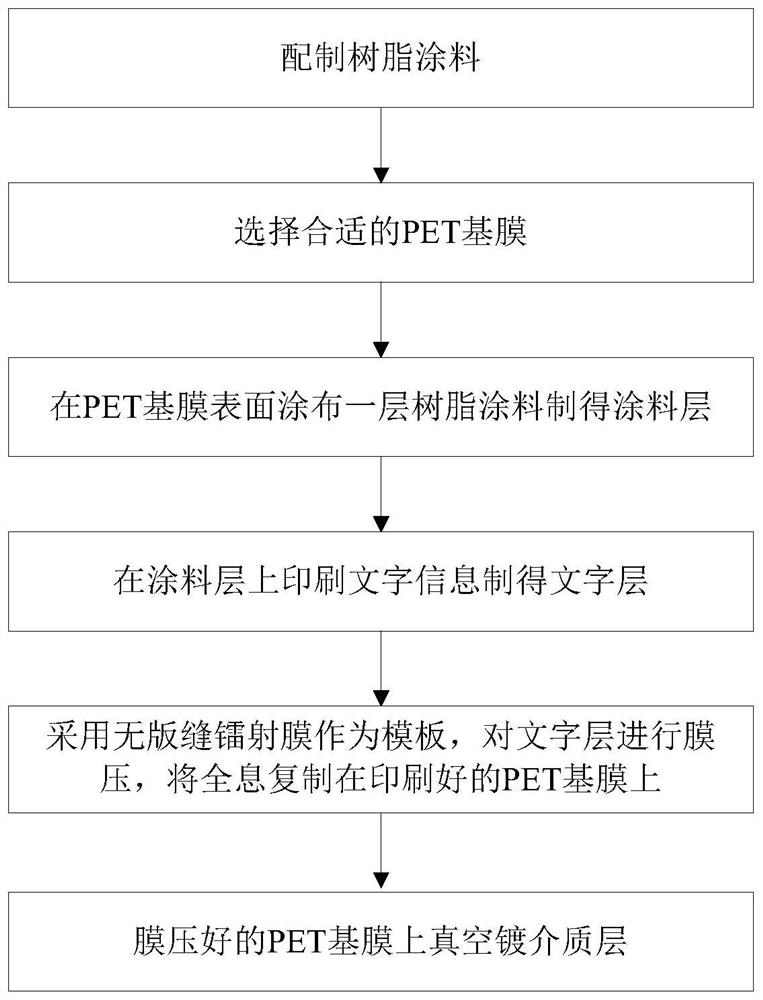

[0035] A method for preparing a laser film with text holography, the process flow chart is as follows figure 1 , including the following steps:

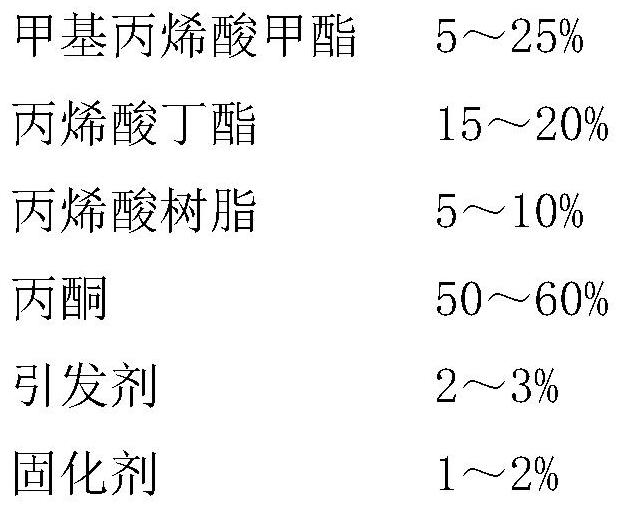

[0036] (1) Resin coating is prepared by weight percentage content, 10% of methyl methacrylate, 15% of butyl acrylate, 10% of acrylic resin, 60% of acetone, 3% of ammonium persulfate, and 2% of aziridine are added in the reactor Mix well, then slowly add ammonia water to adjust the PH value of the paint to 7;

[0037] (2) Coating one deck of prepared resin paint on the PET base film to form a paint layer;

[0038] (3) Print the corresponding text information on the paint layer to form a text layer, in which the text part is not printed, and it is in an empty state;

[0039] (4) The seamless laser film made by traditional technology is used as the template, wherein the seamless laser film is a flattened metal aluminum film, and the printed PET base film is pressed. The film pressure temperature is 100°C. The speed of the press is 70...

Embodiment 2

[0044] A method for preparing a laser film with text holography, comprising the steps of:

[0045] (1) Resin coating is prepared by weight percentage content, 20% of methyl methacrylate, 20% of butyl acrylate, 6% of acrylic resin, 50% of acetone, 2% of ammonium persulfate, and 2% of aziridine are added in the reactor Mix well, then slowly add ammonia water to adjust the pH value of the paint to 8;

[0046] (2) Coating one deck of prepared resin paint on the PET base film to form a paint layer;

[0047] (3) Print the corresponding text information on the paint layer to form a text layer, in which the text part is not printed, and it is in an empty state;

[0048] (4) The seamless laser film made by the traditional process is used as the template, wherein the seamless laser film is a flattened metal aluminum film, and the printed PET base film is pressed, and the film pressure temperature is 90°C. The speed of the press is 80m / min, and the film pressure is 15kg, and the hologr...

Embodiment 3

[0052] A method for preparing a laser film with text holography, comprising the steps of:

[0053] (1) Resin coating is prepared according to weight percent content, and methyl methacrylate 25%, butyl acrylate 16%, acrylic resin 5%, acetone 50%, ammonium persulfate 3%, aziridine 1% are added in the reactor Mix well, then slowly add ammonia water to adjust the PH value of the paint to 7;

[0054] (2) Coating one deck of prepared resin paint on the PET base film to form a paint layer;

[0055] (3) Print the corresponding text information on the paint layer to form a text layer, in which the text part is not printed, and it is in an empty state;

[0056](4) The seamless laser film made by traditional technology is used as the template, wherein the seamless laser film is a flattened metal aluminum film, and the printed PET base film is pressed. The film pressure temperature is 100°C. The speed of the press is 65m / min, and the film pressure is 20kg, and the hologram is copied on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com