Preparation method of ethylenediamine dinitrate

A technology of ethylenediamine dinitrate and ethylenediamine, which is applied in the field of explosive production, can solve the problems of affecting product quality, complicated operation, increasing material cost, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

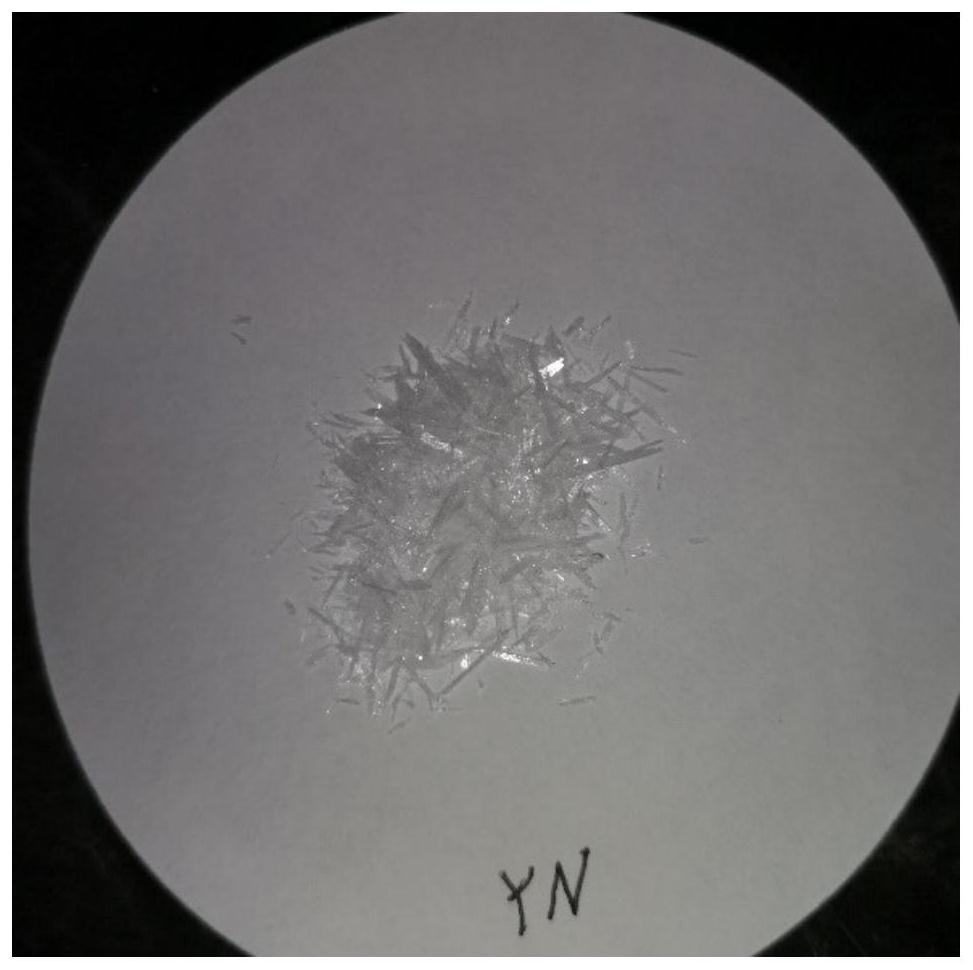

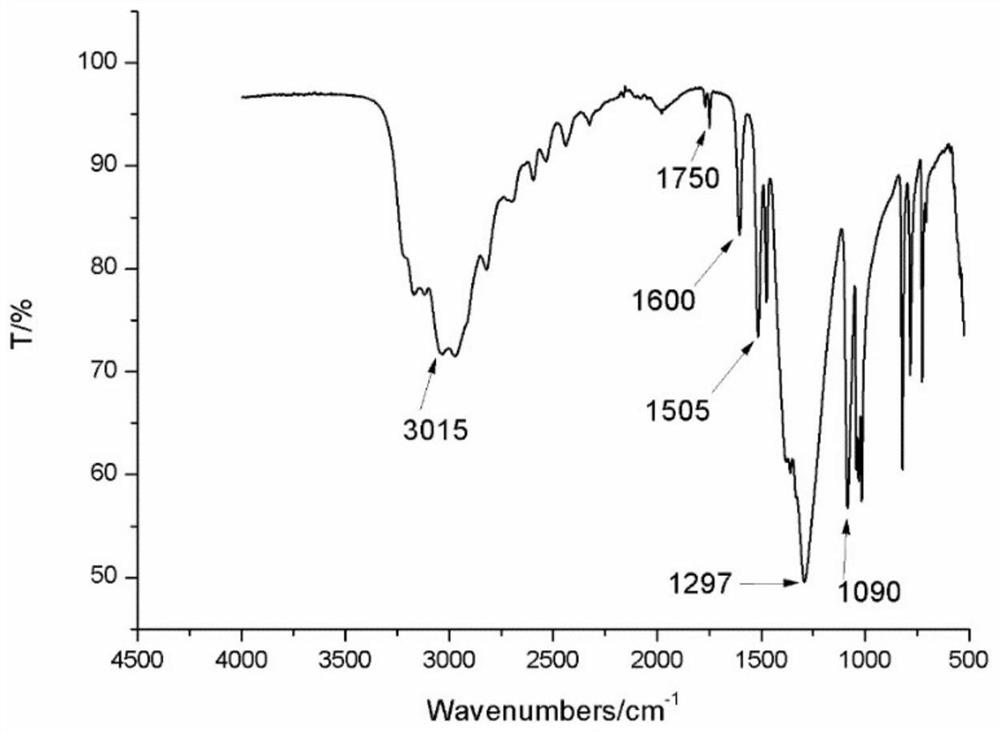

Image

Examples

Embodiment 1

[0020] Put the 250mL three-necked flask in the water tank, add 12.0g of anhydrous ethylenediamine into the three-necked flask, and then add 80mL of solvent (V 水 :V 甲醇 =1:3), stirring, the speed is set to 300r / min. Slowly raise the temperature to 45°C, and at the same time slowly add 37.6g of nitric acid with a mass fraction of 66.0~68.0% dropwise, the dropwise addition is completed within 15 minutes, and the reaction is continued for 10 minutes, and the reaction is completed. Pour all the liquid in the three-neck flask into the beaker prepared in advance, and let it stand for a while until the temperature of the liquid in the beaker is consistent with room temperature, and crystals appear. Filter, wash with anhydrous methanol, dry at 60° C. for 4 hours, and weigh to obtain 31.1 g of ethylenediamine dinitrate, with a yield of 81.1%. Collect the mother liquor filtered in the above steps, replace it with 80mL of solvent and repeat the above steps to obtain 31.6g of ethylenediam...

Embodiment 2

[0022] Put the 250mL three-necked flask in the water tank, add 12.0g of anhydrous ethylenediamine into the three-necked flask, and then add 80mL of solvent (V 水 :V 甲醇 =1:3), stirring, the speed is set to 300r / min. Slowly raise the temperature to 40°C, and at the same time slowly add 37.6g of nitric acid with a mass fraction of 66.0~68.0% dropwise, the dropwise addition is completed within 10 minutes, and the reaction is continued for 10 minutes, and the reaction is completed. Pour all the liquid in the three-neck flask into the prepared beaker and let it stand until it is consistent with room temperature and crystals appear. Filter, wash with anhydrous methanol, dry at 60° C. for 4 hours, and weigh to obtain 30.8 g of ethylenediamine dinitrate, with a yield of 80.4%. The mother liquor filtered in the above steps was collected and replaced with 80 mL of solvent to repeat the above steps to obtain 31.0 g of ethylenediamine dinitrate with a yield of 80.8%.

Embodiment 3

[0024] Put the 250mL three-necked flask in the water tank, add 12.0g of anhydrous ethylenediamine into the three-necked flask, and then add 80mL of solvent (V 水 :V 甲醇 =1:3), stirring, the speed is set to 300r / min. Slowly raise the temperature to 40°C, and at the same time slowly add 37.6g of nitric acid with a mass fraction of 66.0~68.0% dropwise, the dropwise addition is completed within 10 minutes, and the reaction is continued for 10 minutes, and the reaction is completed. Pour all the liquid in the three-neck flask into the prepared beaker and let it stand until it is consistent with room temperature and crystals appear. Filter, wash with anhydrous methanol, dry at 60° C. for 8 hours, and weigh to obtain 30.6 g of ethylenediamine dinitrate, with a yield of 79.8%. The mother liquor filtered in the above steps was collected and replaced with 80 mL of solvent to repeat the above steps to obtain 30.9 g of ethylenediamine dinitrate with a yield of 80.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com