Method for improving dielectric constant of polypropylene film

A polypropylene film, high dielectric constant technology, applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc. problems, to achieve the effect of improving interface compatibility, increasing dielectric constant, and multi-contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

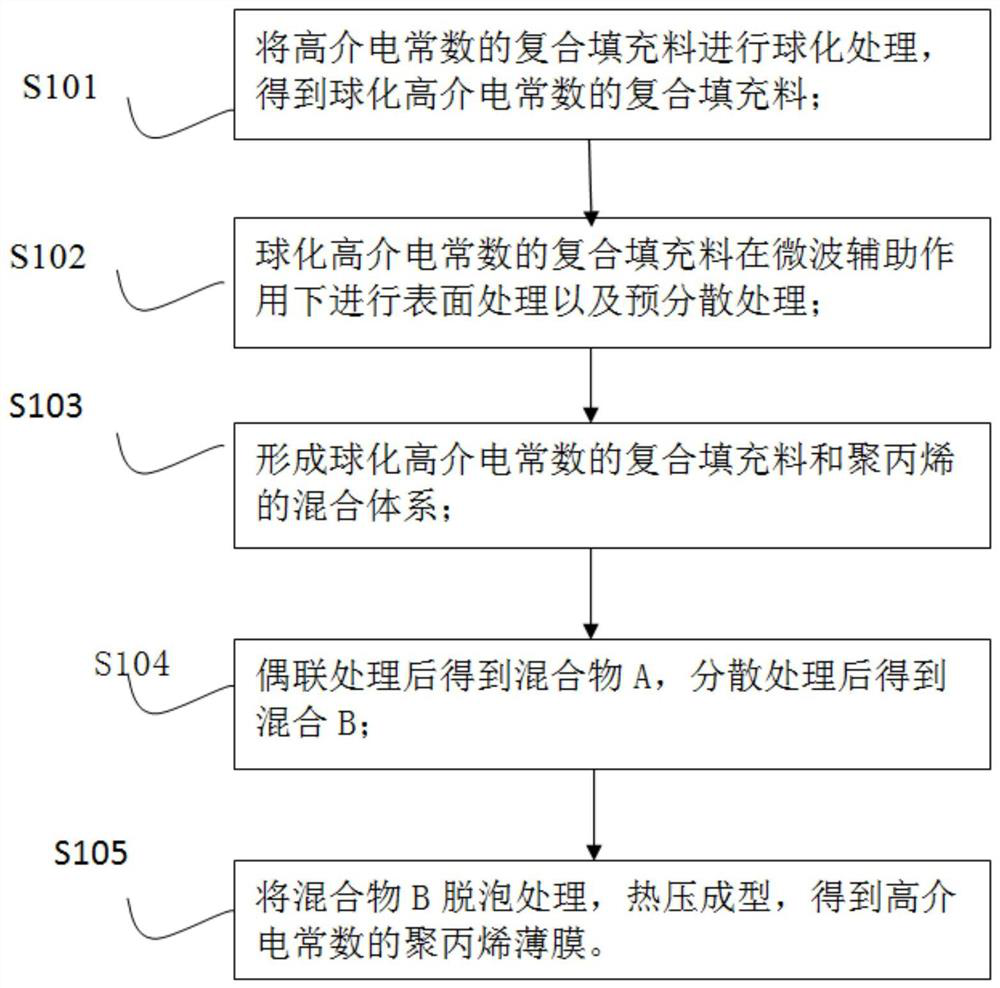

Image

Examples

Embodiment 1

[0033] In the present embodiment, a kind of method that improves the dielectric constant of polypropylene film is provided, and described method comprises the following steps:

[0034] S1 Place the high dielectric constant composite filler in a spheroidizing device that is fed into the DC arc plasma flame flow, and spheroidize under the action of surface tension to obtain an average particle size of 95-270nm and an average pore size of 350- 650nm spheroidized high dielectric constant composite filler, and the temperature in the spheroidization device is 45-200°C; the high dielectric constant composite filler includes a volume ratio of 1-4:1-2:2 -7: 1-4 ceramic particles, barium titanate, carbon nanotubes, titanium dioxide; compounding specific proportions of high dielectric constant components not only synergistically increases the dielectric constant of polypropylene films, but also ensures The mechanical properties of the polypropylene film can reduce the dielectric loss, an...

Embodiment 2

[0042] This embodiment should be understood as including all the features of the foregoing embodiments, and further optimized on the basis thereof, therefore, this embodiment provides a method for improving the dielectric constant of polypropylene film, said method comprising the following steps:

[0043] S1 Place the high dielectric constant composite filler in a spheroidizing device that is fed into the DC arc plasma flame flow, and spheroidize under the action of surface tension to obtain a spheroid with an average particle size of 95nm and an average pore size of 350nm. Composite filler with high dielectric constant;

[0044] S2 Add the spheroidized high dielectric constant composite filler to the process of preparing the polypropylene film after surface treatment and pre-dispersion treatment under the assistance of microwaves to increase the dielectric constant of the polypropylene film, and In this embodiment, the high dielectric constant composite filler includes porcel...

Embodiment 3

[0051] This embodiment should be understood as including all the features of any of the preceding embodiments, and further optimized on the basis of it, therefore, in this embodiment, a method for improving the dielectric constant of a polypropylene film is provided, and the method includes The following steps:

[0052] S1 Heat the composite filler with high dielectric constant in a spheroidizing device fed with a DC arc plasma flame, and spheroidize under the action of surface tension to obtain spheres with an average particle size of 270nm and an average pore size of 650nm A composite filler with a high dielectric constant, and the heating temperature is 200°C; the composite filler with a high dielectric constant includes porcelain particles, barium titanate, carbon nanotubes, and titanium dioxide with a volume ratio of 4:1:7:4. ;

[0053] S2 Add the spheroidized high dielectric constant composite filler to the process of preparing the polypropylene film after surface treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com