Abrasive material for large-diameter silicon wafer and production method thereof

A technology for abrasive materials and production methods, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve the problem that the ratio of various raw materials of abrasive materials is not easy to grasp, and achieve processing stability, increased effect, particle size, etc. selective enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

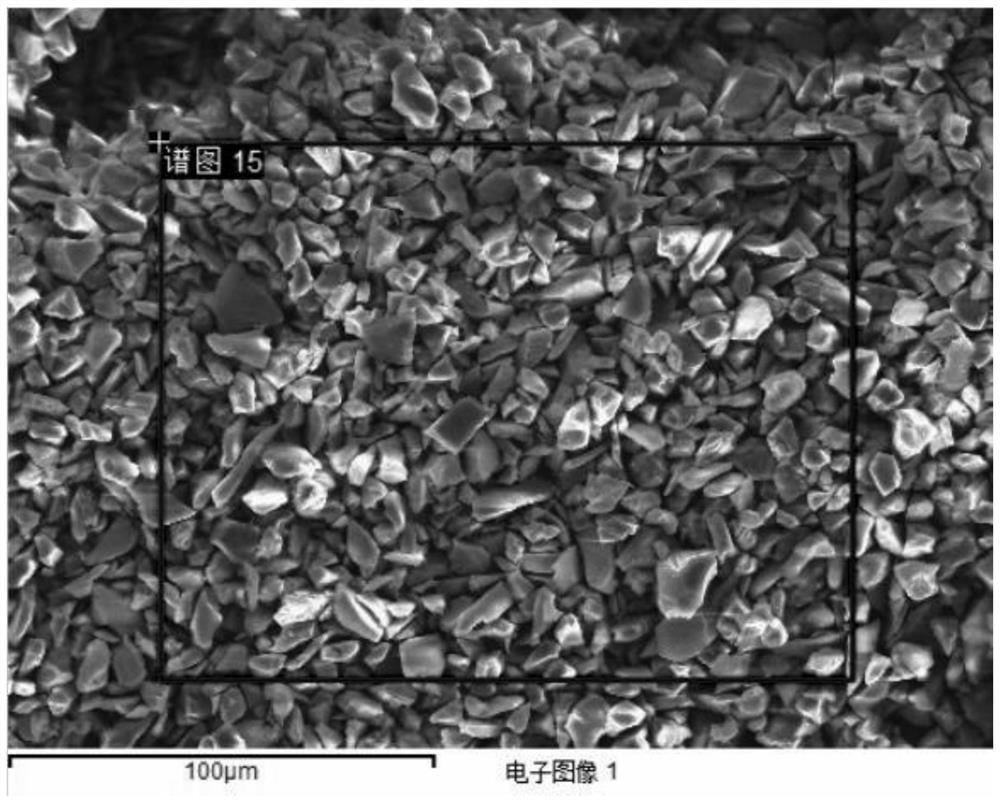

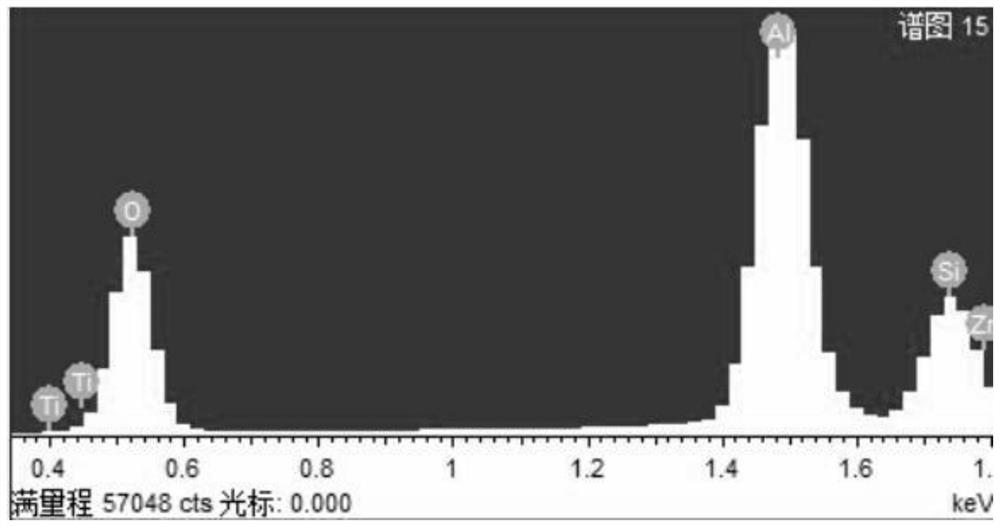

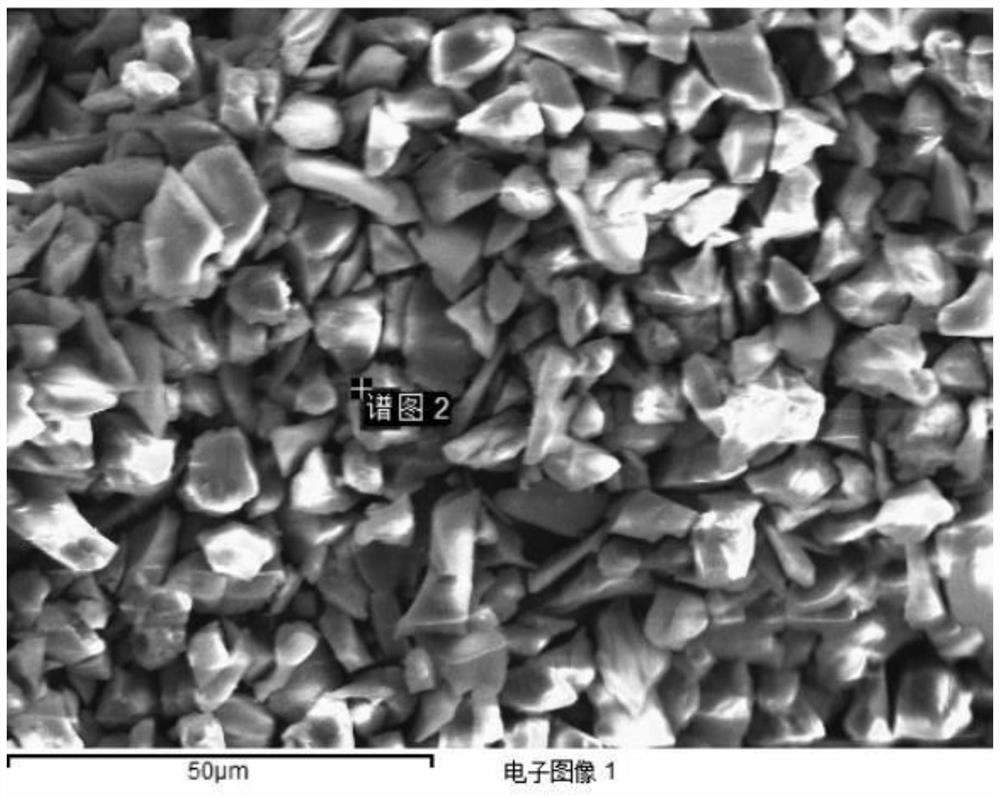

[0030] An abrasive material for large-diameter silicon wafers and a production method thereof, comprising the following raw materials in parts by mass: 45% zirconium silicate ZrSiO4, 55% alumina Al2O3, a small amount of catalyst and a small amount of binding agent, silicic acid The mass of zirconia in zirconium ranges from 25% to 35%.

[0031] First, the selected zirconium silicate and the selected alumina are introduced into the mixing bin according to the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com