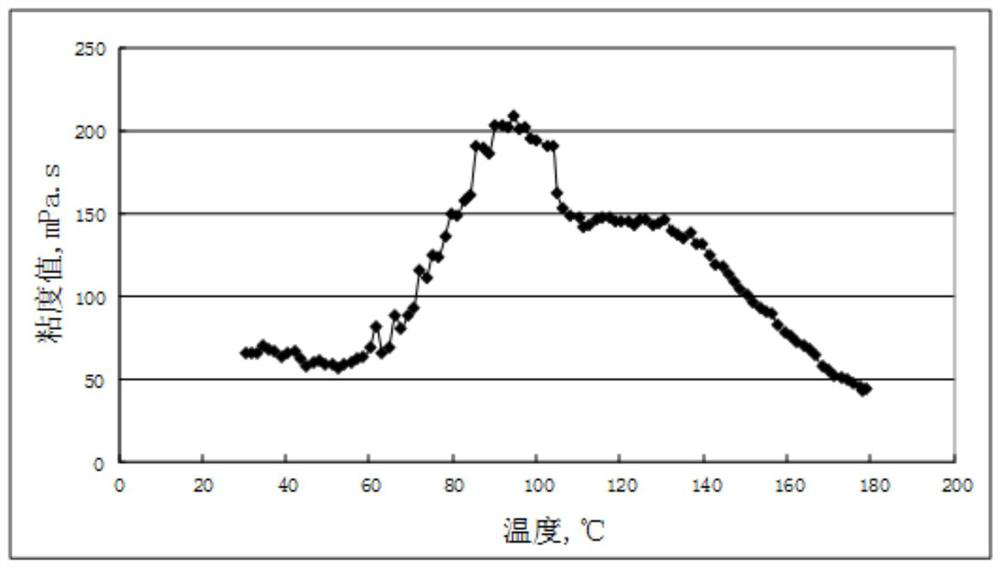

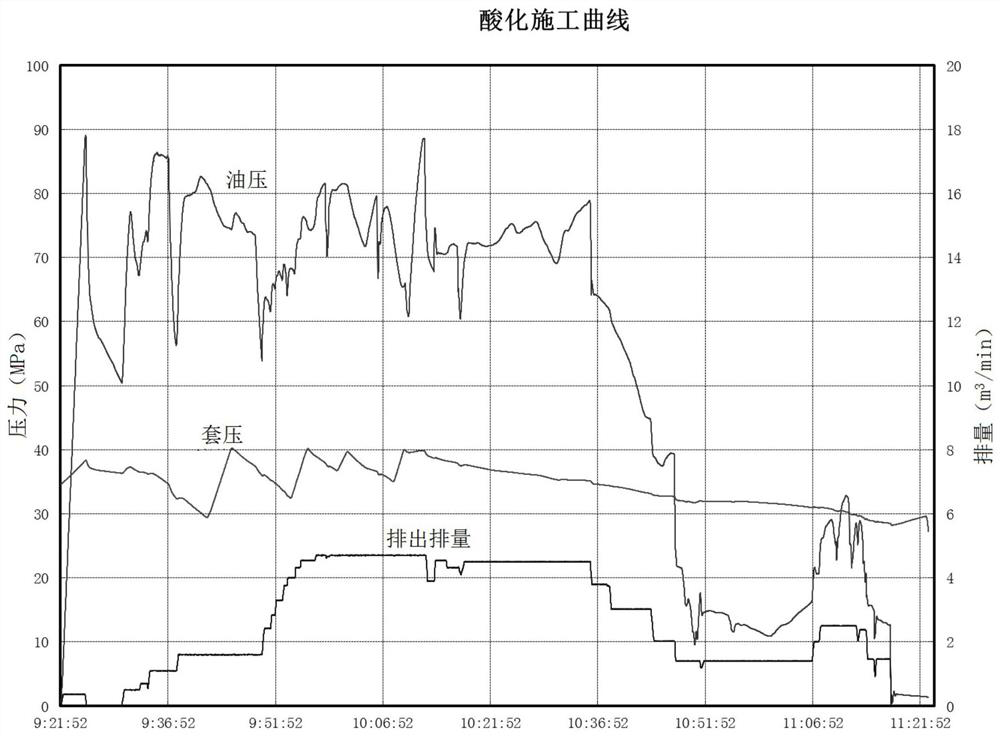

A kind of high temperature diverting acid composition and preparation method thereof

A technology of diverting acid and composition, applied in the field of high-temperature diverting acid composition and preparation thereof, can solve the problems of no temperature resistance test data, complex formation composition, difficult control of secondary precipitation, etc., to improve the acidification effect , Improve the effect of iron stabilization and reduce the effect of construction pump pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

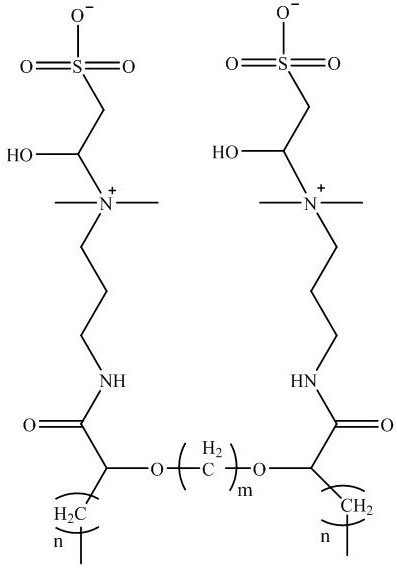

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides a high temperature steering acid composition with a total volume of 100m 3 , specifically including the following composition: 61.5m of industrial hydrochloric acid with a concentration of 31.6% 3 , corrosion inhibitor 1000kg, iron ion stabilizer 1000kg, corrosion inhibitor 500kg, iron ion stabilizer auxiliary 500kg, high temperature stabilizer 75kg, retarder 5m 3 , steering agent 3m 3 , and the rest is water.

[0090] Wherein, the corrosion inhibitor includes aldosterone amine condensate, alkynol, synergist, alcohol solvent and first dispersant, and the mass ratio is 30:12:5:15:1. Among them, the aldosterone amine condensate contains three or more N and O atoms in total and contains π bonds.

[0091] The aldosterone amine condensate was obtained by reacting aldehydes, ketones and amines with a molar ratio of 0.8:1.2:1.2 at 85 °C for 240 min.

[0092] Aldehydes include formaldehyde, trioxymethylene, and benzaldehyde in a mass ratio of 1:2:1....

Embodiment 2

[0111] This embodiment provides a high temperature steering acid composition with a total volume of 100m 3 , specifically including the following composition: 61.5m of industrial hydrochloric acid with a concentration of 31.6% 3 , corrosion inhibitor 1000kg, iron ion stabilizer 1500kg, corrosion inhibitor 500kg, iron ion stabilizer auxiliary 1000kg, high temperature stabilizer 75kg, retarder 5m 3 , steering agent 4m 3 , and the rest is water.

[0112] Wherein, the corrosion inhibitor includes aldosterone amine condensate, alkynol, synergist, alcohol solvent and first dispersant, and the mass ratio is 40:20:20:25:5. Among them, the aldosterone amine condensate contains three or more N and O atoms in total and contains π bonds.

[0113] The aldosterone amine condensate was obtained by reacting aldehydes, ketones and amines with a molar ratio of 0.8:1.6:1.5 at 90 °C for 260 min.

[0114] Aldehydes include formaldehyde, trioxymethylene, and benzaldehyde in a mass ratio of 1:5:...

Embodiment 3

[0134] This embodiment provides a high temperature steering acid composition with a total volume of 100m 3 , specifically including the following composition: 61.5m of industrial hydrochloric acid with a concentration of 31.6% 3 , corrosion inhibitor 2000kg, iron ion stabilizer 1500kg, corrosion inhibitor 1000kg, iron ion stabilizer auxiliary 1500kg, high temperature stabilizer 100kg, retarder 6m 3 , steering agent 6m 3 , and the rest is water.

[0135] The corrosion inhibitor includes aldosterone amine condensate, alkynol, synergist, alcohol solvent and first dispersant, and the mass ratio is 60:12:5:15:10. Among them, the aldosterone amine condensate contains three or more N, O atoms in total and contains π bonds.

[0136] The aldosterone amine condensate was obtained by reacting aldehydes, ketones and amines with a molar ratio of 1:1.4:1.5 at 90 °C for 260 min.

[0137] Aldehydes include formaldehyde, trioxymethylene, and benzaldehyde in a mass ratio of 1:3:3.

[0138]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com