A High Insulation and High Stability Modified Transformer Oil

A technology of transformer oil and high stability, applied in the field of transformer oil, can solve the problems of poor stability of transformer oil and inability of transformer oil to be uniform, and achieve the effects of increasing compatibility, fewer types of raw materials, and good photocatalytic activity performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

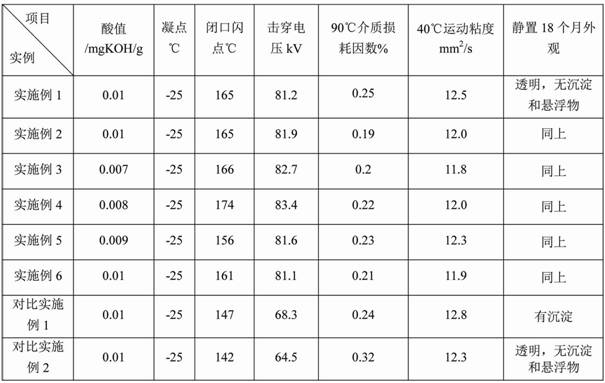

Examples

Embodiment 1

[0019] A high insulation and high stability modified transformer oil, comprising base oil and modified nano-titanium oxide of 0.1% by weight of the base oil, the preparation method of the modified nano-titanium dioxide comprises the following steps:

[0020] (1) Put titanium dioxide nanoparticles into a ball mill, add dodecyltrimethoxysilane, the mass ratio of dodecyltrimethoxysilane to titanium dioxide nanoparticles is 0.1:1, heat to 50°C, mix and ball mill for 1h ;

[0021] (2) Add oleic acid to the mixture obtained in step (1), the ratio of oleic acid to titanium dioxide nanoparticles is 40mL: 1g, then continue to heat up to 85°C, first stir mechanically, the speed of mechanical stirring is 1500r / min, time for 50 minutes, then ultrasonically oscillate, the power of ultrasonic oscillation is 800W, and the time is 25min, and finally washed with ethanol, filtered and dried to obtain modified nano-titanium dioxide.

[0022] The titanium dioxide nanoparticles are gold-red phase...

Embodiment 2

[0028] A high-insulation and high-stability modified transformer oil, comprising base oil and modified nano-titanium oxide of 0.2% by weight of the base oil, the preparation method of the modified nano-titanium dioxide comprises the following steps:

[0029] (1) Put titanium dioxide nanoparticles into a ball mill, add dodecyltrimethoxysilane, the mass ratio of dodecyltrimethoxysilane to titanium dioxide nanoparticles is 0.05:1, heat to 40°C, mix and ball mill for 3h ;

[0030] (2) Add oleic acid to the mixture obtained in step (1), the ratio of oleic acid to titanium dioxide nanoparticles is 50mL: 1g, then continue to heat up to 80°C, first stir mechanically, the speed of mechanical stirring is 1700r / min, time for 40 minutes, then ultrasonically oscillate, the power of ultrasonic oscillation is 1000W, and the time is 20min, and finally washed with ethanol, filtered and dried to obtain modified nano-titanium dioxide.

[0031] The titanium dioxide nanoparticles are gold-red pha...

Embodiment 3

[0037] A modified transformer oil with high insulation and high stability, comprising base oil and modified nano-titanium oxide of 0.5% by weight of the base oil, the preparation method of the modified nano-titanium dioxide comprises the following steps:

[0038] (1) Put titanium dioxide nanoparticles into a ball mill, add dodecyltrimethoxysilane, the mass ratio of dodecyltrimethoxysilane to titanium dioxide nanoparticles is 0.12:1, heat to 45°C, mix and ball mill for 2 hours ;

[0039] (2) Add oleic acid to the mixture obtained in step (1), the ratio of oleic acid to titanium dioxide nanoparticles is 50mL: 1g, then continue to heat up to 80°C, first mechanically stir, the mechanical stirring speed is 1600r / min, time for 40 minutes, then ultrasonically oscillate, the power of ultrasonic oscillation is 1000W, and the time is 20min, and finally washed with ethanol, filtered and dried to obtain modified nano-titanium dioxide.

[0040] The titanium dioxide nanoparticles are gold-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com