Domestication and breeding method of tetrahydrofuran efficient degradation strain

A technology of tetrahydrofuran and bacteria, applied in chemical instruments and methods, methods of using microorganisms, separation methods, etc., can solve problems such as long cycle, and achieve the effect of shortening the experimental period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

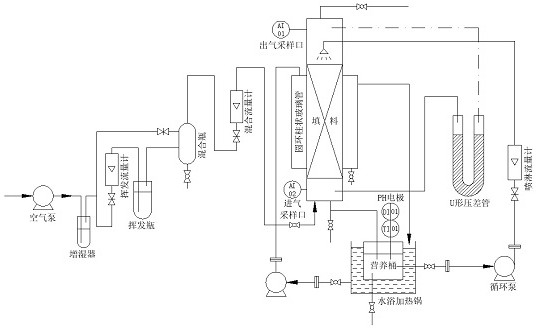

Image

Examples

Embodiment 1

[0048] Sample Collection

[0049] The wastewater and sludge in the aeration tank of a chemical company in Chongqing were collected with sterile sampling bottles, and placed in a constant temperature incubator for overnight cultivation at a temperature of 35°C.

Embodiment 2

[0051] Enrichment and primary screening of specific strains

[0052] Choose ten 100mL Erlenmeyer flasks and fill them with 30mL LB medium, and five 100mL Erlenmeyer flasks with 30mL MM medium respectively, and put them in a high-pressure steamer for 30min. After mixing the collected water samples and sludge, put them into the above-mentioned 5 Erlenmeyer flasks containing LB medium, put them in a shaker with a temperature of 37°C and a rotation speed of 180r / min as the first generation of culture for 10 hours; the first generation of LB Inoculate the culture medium with a volume fraction of 2% into another 5 LB medium, and put it into a shaker under the same conditions for second-generation culture for 5 hours; finally, add the second-generation LB medium with a volume fraction of 10% The inoculum amount was inserted into the sterilized inorganic salt medium with tetrahydrofuran as the only carbon source, placed in a shaker at a temperature of 32°C and a rotation speed of 130 ...

Embodiment 3

[0054] Enrichment culture of specific bacterial flora after screening

[0055] Select 5 Erlenmeyer flasks and fill them with 50mL LB medium respectively, and fill them with a certain amount of polyethylene foam as seeds, and then sterilize them. Wait until OD600 in embodiment 2 nm When it is about 0.8, inoculate the second-generation LB medium at a volume fraction of 2% to the LB medium containing polyethylene foam as seeds, and then put it into a shaking table with a temperature of 37°C and a rotation speed of 180r / min. During the culture period, measure OD600 every 2 hours nm , Strictly control the OD600 of the fermentation broth of the strain nm =1.2(±0.02).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com