Technological method for producing 3-hydroxybutanone by utilizing wheat B starch

A technology of hydroxybutanone and process methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, separation/purification of carbonyl compounds, etc., to achieve the effect of reducing raw material costs, realizing high added value utilization, and high added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation of sugar solution: add water to the separated and washed starch to adjust the slurry concentration, adjust the concentration of starch slurry to 10-15Bé, add an appropriate amount of amylase according to the total amount of starch to carry out double-enzyme sugar production (add the amount of enzyme preparation according to the amount recommended by the manufacturer), After the saccharification is completed, centrifuge and collect the supernatant part for 3-hydroxybutanone fermentation.

[0041] Seed medium: glucose 50g / L, yeast extract 10g / L, corn steep liquor 10g / L, sodium chloride 5g / L, prepared with drinking water, pH 7.0.

[0042] 3-Hydroxybutanone Fermentation

[0043] Get the starch sugar solution, adjust it to an appropriate glucose concentration (120-160g / L), and prepare a 3-hydroxybutanone fermentation medium. Control experiments were formulated with oral glucose. After the culture medium is sterilized, strains are added for fermentation.

[004...

Embodiment 1

[0046] The influence of embodiment 1 culture medium on the fermentation of 3-hydroxybutanone

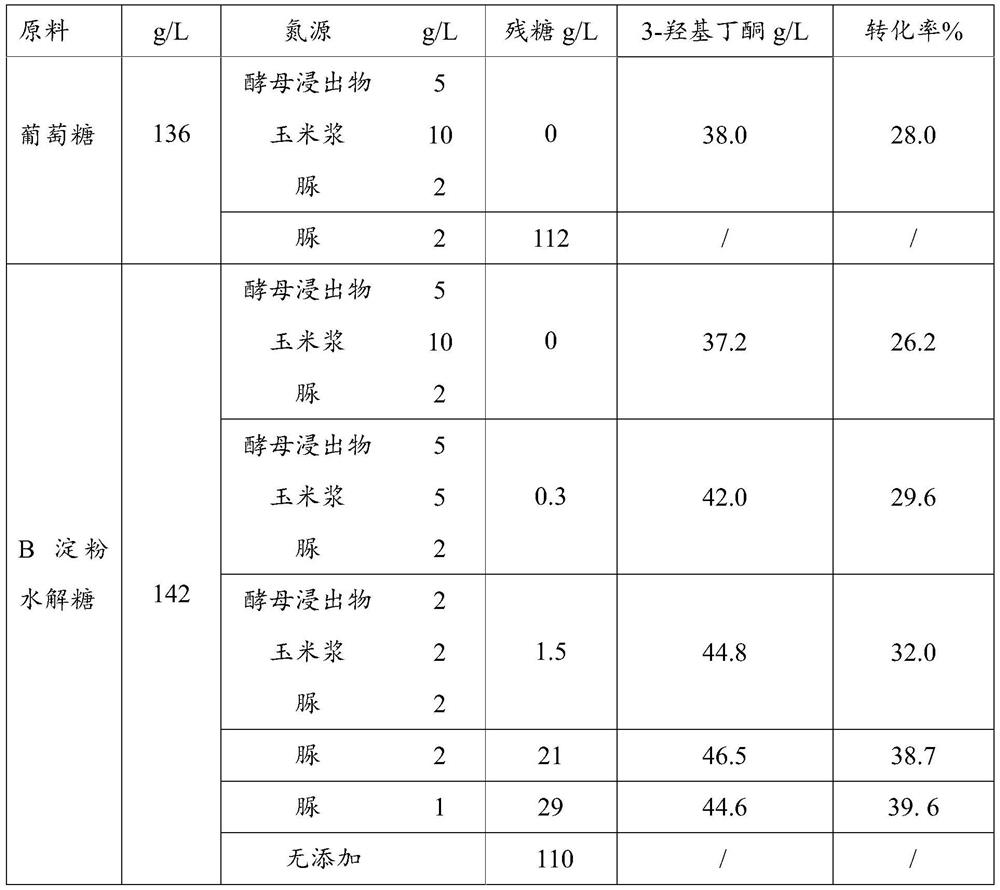

[0047] The experiment used glucose as a control to carry out the 3-hydroxybutanone fermentation experiment to investigate the effect of nitrogen source addition on the fermentation of wheat B starch syrup 3-hydroxybutanone. The results are shown in the following table:

[0048]

[0049] The experimental results showed that the fermentation of 3-hydroxybutanone with B starch syrup as raw material did not require the addition of yeast extract and corn steep liquor, and the yield and conversion rate of 3-hydroxybutanone were significantly higher than those of glucose.

Embodiment 2B

[0050] Embodiment 2 takes B starch syrup as raw material 50L fermentation

[0051] Fresh wheat B starch slurry is used to prepare starch sugar by conventional double-enzyme sugar production process. After saccharification, centrifuge to remove solid residue. The residue can be washed with an equal volume of water, centrifuged, combined with centrifuged supernatant, adjust the appropriate glucose concentration, and add to fermentation In jars, sterilized. Another 2g / L urea was added (sterilized separately, added before inoculation). Inoculate according to the inoculum amount of 5%, and the initial sugar concentration after inoculation is 138g / L, and the appropriate temperature and relative dissolved oxygen concentration are controlled during the fermentation process. Cultivate for 58 hours, measure the glucose concentration and drop below 0.1g / L, and end the fermentation. A total of 35 L of fermentation broth was collected, and the content of 3-hydroxybutanone was determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com