Method for chemical crosslinked modified carbon nanotube fibers

A carbon nanotube fiber and chemical cross-linking technology, which is applied in the fields of fiber treatment, natural fiber, and fiber chemical characteristics, can solve the problems of poor comprehensive performance of carbon nanotube fibers, easy creep of carbon nanotube fibers, and poor dispersion of carbon nanotubes. Equal problem, to achieve the effect of reducing the generation of micro-nano cracks in carbon nanotube fibers, excellent mechanical stability, and improving Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

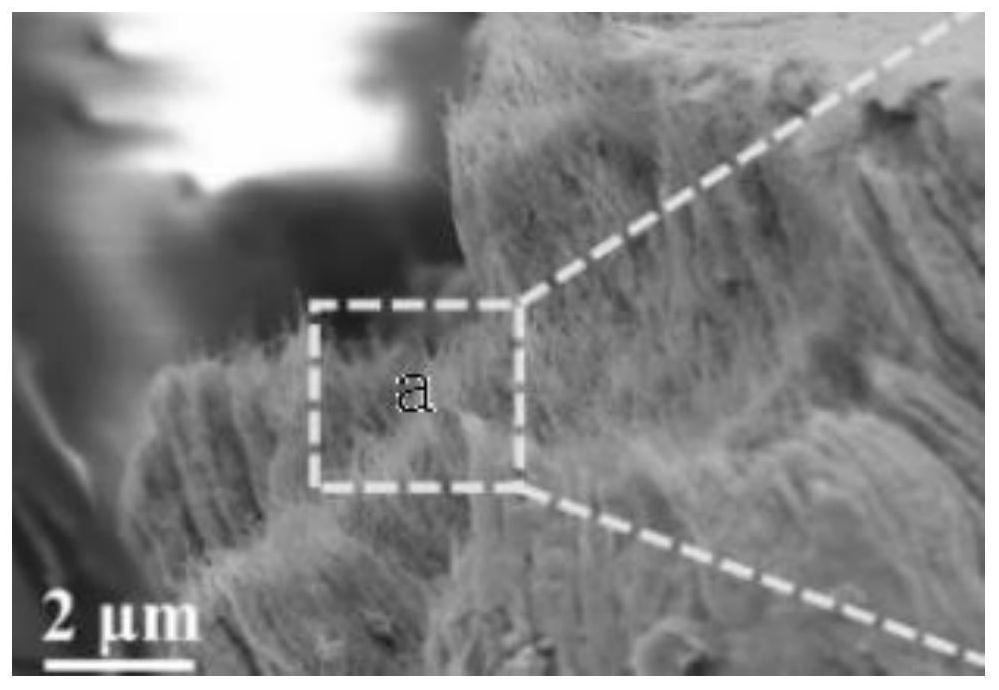

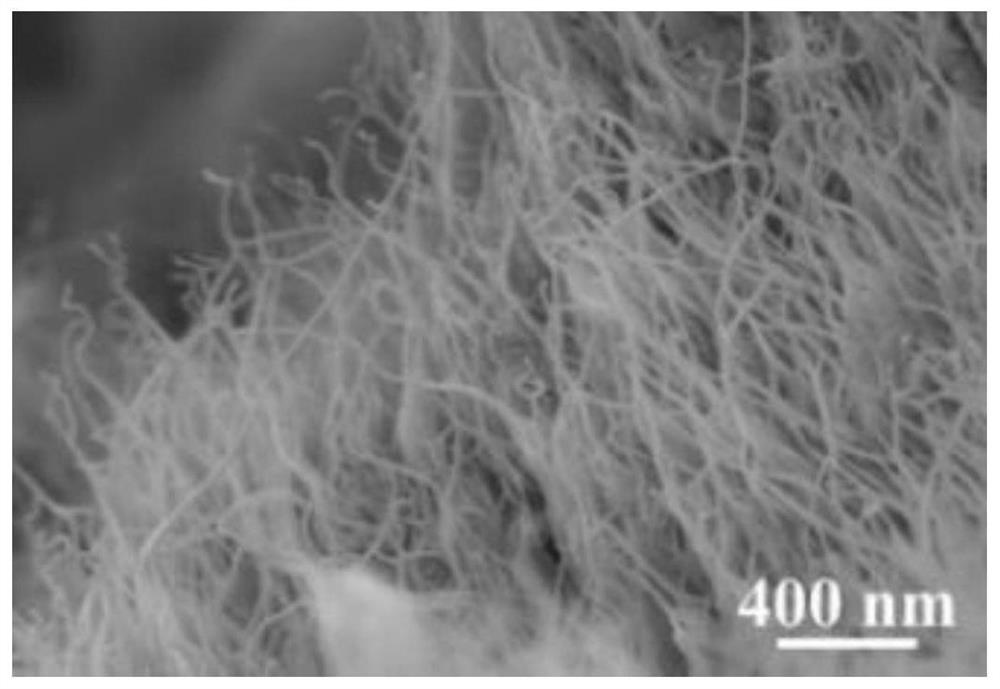

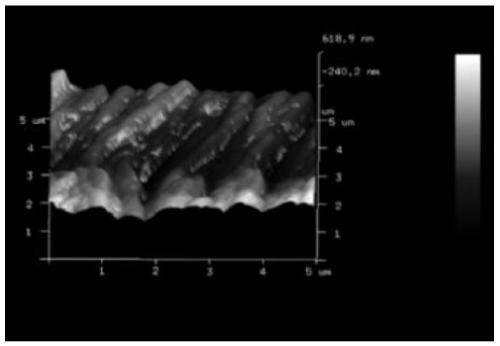

Image

Examples

specific Embodiment approach 1

[0045] Embodiment 1: A method of chemically cross-linking modified carbon nanotube fibers according to the present embodiment is carried out in the following steps:

[0046] 1. Preparation of spinning stock solution: dissolve hyaluronic acid in deionized water to obtain a hyaluronic acid solution with a concentration of 5 mg / mL, then add carbon nanotubes to the hyaluronic acid solution and perform ultrasonic dispersion treatment to obtain a spinning solution. Silk stock solution; the mass ratio of carbon nanotubes to hyaluronic acid is 8:5; the parameters of the ultrasonic dispersion treatment are: ultrasonic power is 180W, ultrasonic time is 20min;

[0047] 2. Preparation of hyaluronic acid / carbon nanotube fibers: use wet spinning technology to inject the spinning solution obtained in step 1 into the rotating coagulation solution at a speed of 50mL / h through the syringe needle, and the rotation speed is 20r / min , to obtain hyaluronic acid / carbon nanotube fibers; the diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com