A production method capable of reducing shrinkage of wool yarn

A production method and wool yarn technology, applied in the field of spinning, can solve the problems of uneven fabric, poor stability, uneven evenness, etc., achieve uniform yarn steaming, reduce wool fiber shrinkage, and color rate uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A production method capable of reducing shrinkage of wool yarn described in the present invention will be described in further detail below through specific examples.

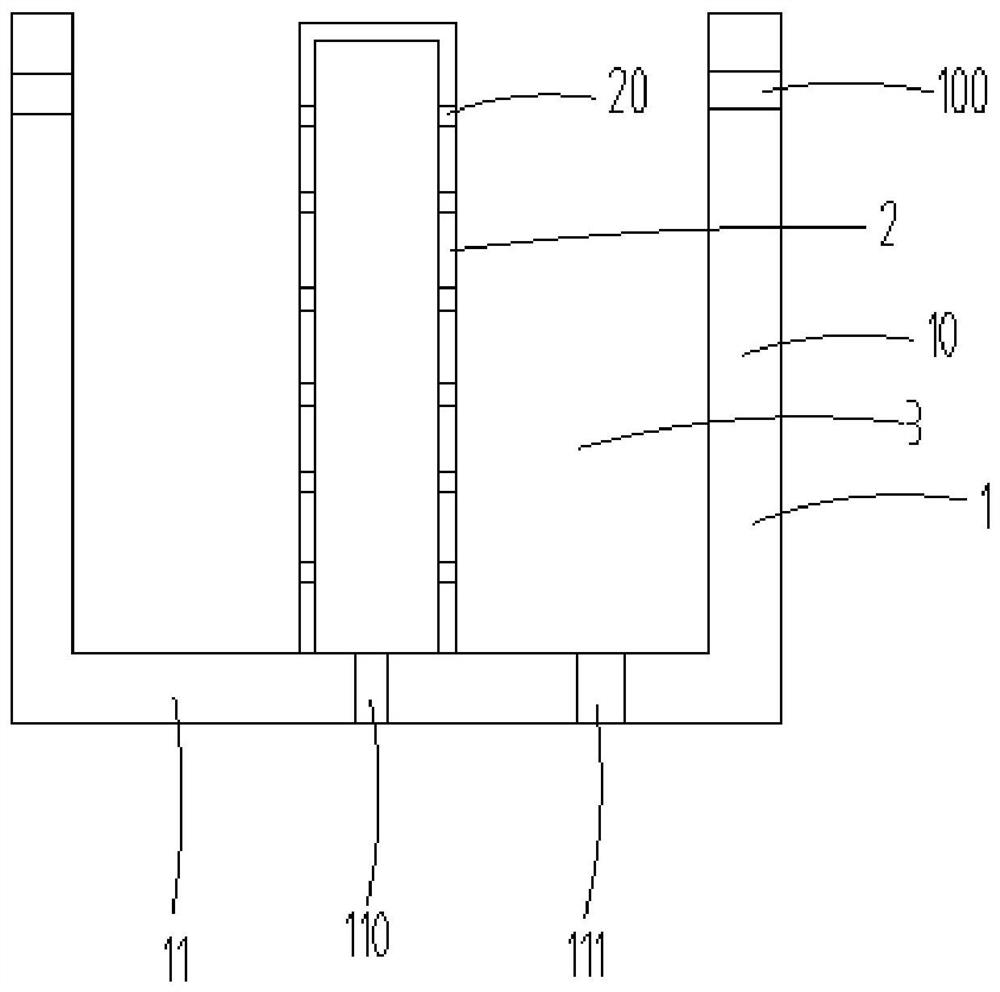

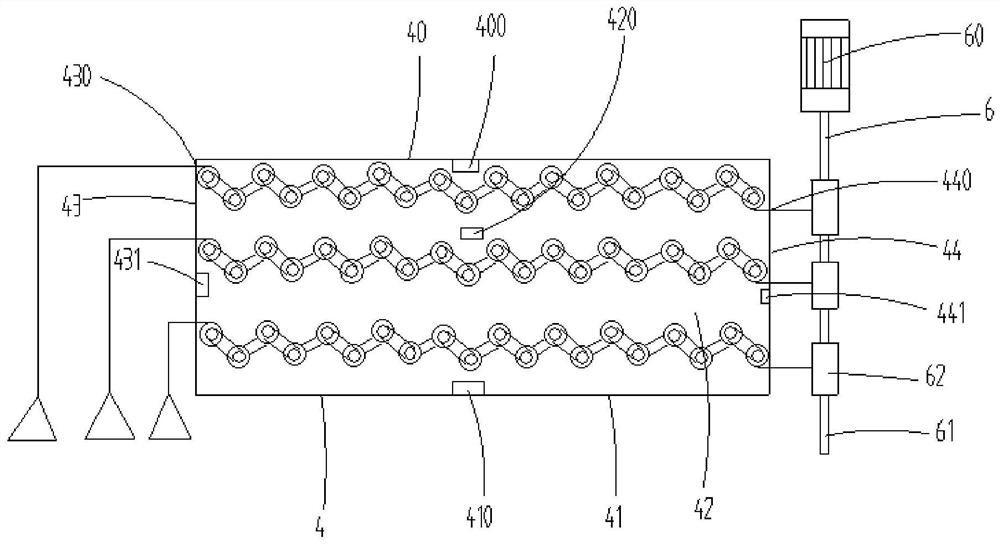

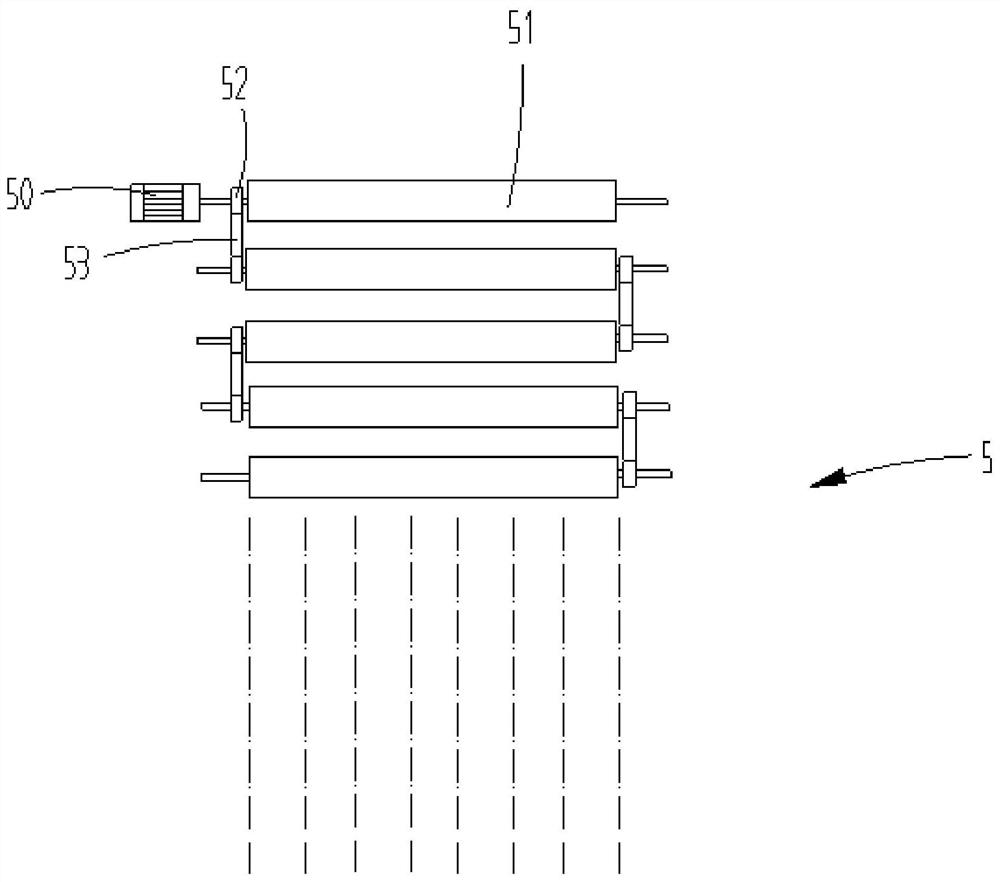

[0014] A production method capable of reducing the shrinkage of wool yarn, comprising the following steps: A, pre-loosening, pouring a raw material wool ball into a pre-loose wool ball, the gram weight of the raw material wool ball being 18-20 g / m , the gram weight of the pre-loose wool ball is 10 grams / meter; B, dyeing, the dye vat is improved into an internal and external osmotic dye vat, and then the pre-loose wool ball is put into the internal and external osmotic dye vat to carry out dyeing regularly, please refer to figure 1, the internal and external osmotic dye vats include: a cylinder body 1 and a hollow column 2 arranged in the center of the cylinder body 1, a storage space 3 for accommodating pre-loose wool balls is formed between the cylinder body 1 and the hollow column 2, the The cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com