Laminated electrolytic capacitor and manufacturing method thereof

A technology of electrolytic capacitors and aluminum electrolytic capacitors, which is applied in the field of capacitors, can solve the problems of increased heat generation of capacitors, the inability to completely eliminate pinholes in electrolytic paper, and shortened lifespan, and achieve the goals of improving loss and heat generation, increasing capacity extraction rate, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

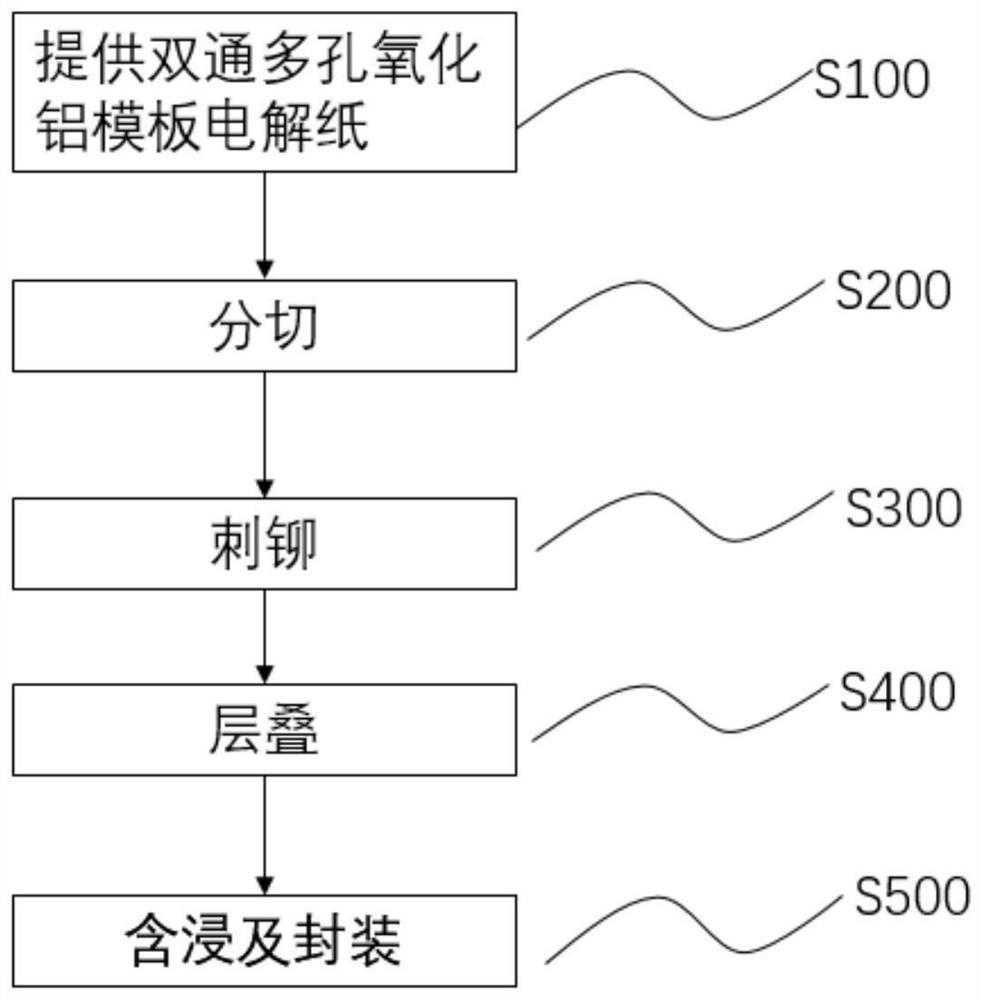

[0060] In this embodiment, the manufacturing process of laminated aluminum electrolytic capacitors, such as figure 1 shown, including:

[0061] (1) Provide double-pass porous alumina template electrolytic paper with a thickness of 40 μm and a pore size of 100 nm;

[0062] (2) Slitting: cutting the anode foil, cathode foil, and double-pass AAO template electrolytic paper into specified sizes;

[0063] (3) Riveting: piercing and riveting the anode foil and cathode foil;

[0064] (4) Lamination: Laminate sequentially according to cathode foil-double-pass porous alumina template electrolytic paper-anode foil-double-pass porous alumina template electrolytic paper-cathode foil;

[0065] (5) Impregnation and encapsulation: The laminated cores are impregnated with an electrolyte solution, and then encapsulated in an aluminum shell to obtain a laminated aluminum electrolytic capacitor.

Embodiment 2

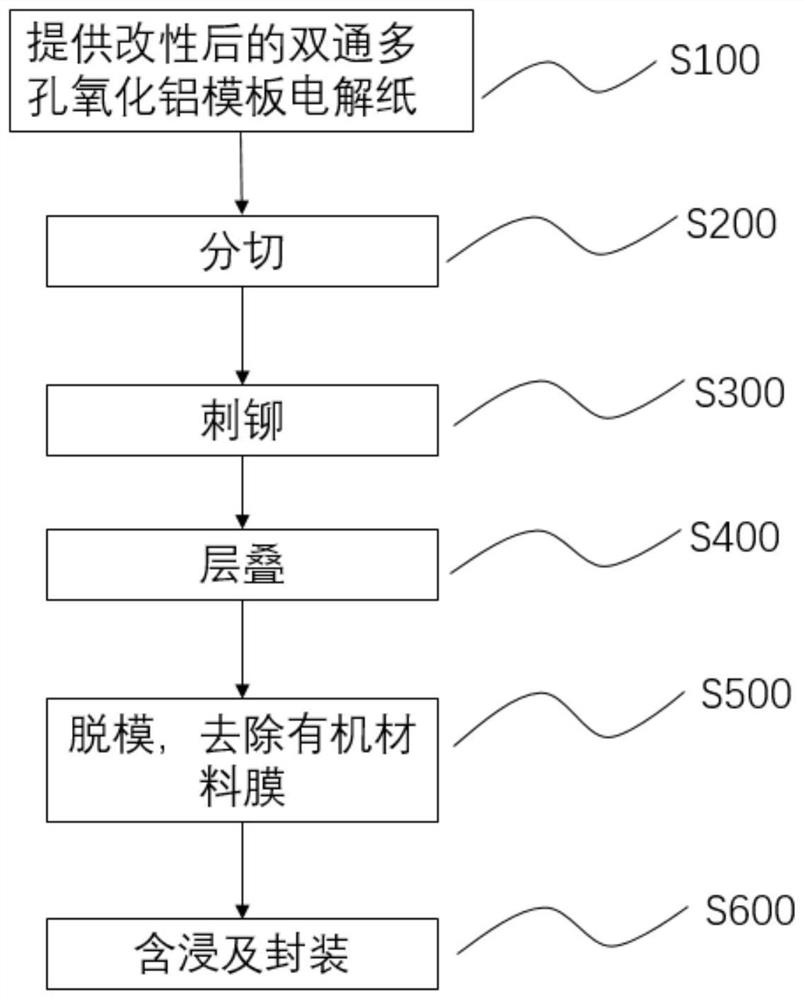

[0067] In this embodiment, the manufacturing process of laminated aluminum electrolytic capacitors, such as figure 2 shown, including:

[0068] (1) Dissolve methyl methacrylate in acetone to prepare a solution with a mass fraction of 0.5%; immerse a double-pass AAO template with a thickness of 40 μm and a pore size of 100 nm in the acetone solution of methyl methacrylate above, at 40 ° C Immersed for 3 minutes, and then treated at 150°C for 20 minutes to obtain a modified double-pass AAO template electrolytic paper;

[0069] (2) Slitting: cutting the anode foil, cathode foil and the modified double-pass AAO template electrolytic paper into specified sizes;

[0070] (3) Riveting: piercing and riveting the anode foil and cathode foil;

[0071] (4) Lamination: Laminate sequentially according to cathode foil-modified double-pass AAO template electrolytic paper-anode foil-modified double-pass AAO template electrolytic paper-cathode foil;

[0072] (5) Demolding: Wrap the laminat...

Embodiment 3

[0075] In this embodiment, the manufacturing process of laminated aluminum electrolytic capacitors, such as figure 2 shown, including:

[0076] (1) Ethyl methacrylate was dissolved in ethanol to prepare a solution with a mass fraction of 1%; the double-pass AAO template with a thickness of 20 μm and a pore size of 60 nm was immersed in the ethanol solution of ethyl methacrylate above, at 20 ° C Immersed for 2 minutes, and then treated at 120°C for 30 minutes to obtain a modified double-pass AAO template electrolytic paper;

[0077] (2) Slitting: cutting the anode foil, cathode foil and the modified double-pass AAO template electrolytic paper into specified sizes;

[0078] (3) Riveting: piercing and riveting the anode foil and cathode foil;

[0079] (4) Lamination: Laminate sequentially according to cathode foil-modified double-pass AAO template electrolytic paper-anode foil-modified double-pass AAO template electrolytic paper-cathode foil;

[0080] (5) Demolding: Wrap the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com