High-precision and high-stability temperature control system for chaotic semiconductor laser

A temperature control system, semiconductor technology, applied in the direction of semiconductor lasers, temperature control, control/regulation systems, etc., can solve problems that have not been mentioned, have not been specified, and reduce steady-state errors, so as to improve control accuracy and temperature regulation The effect of speed, guaranteed stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

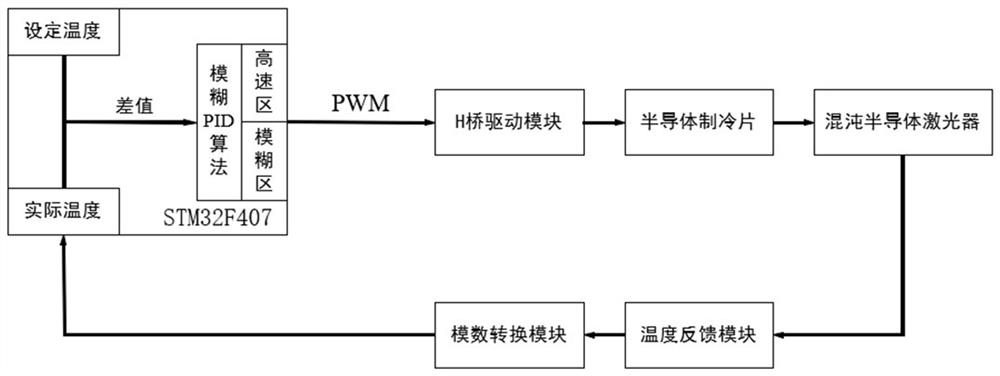

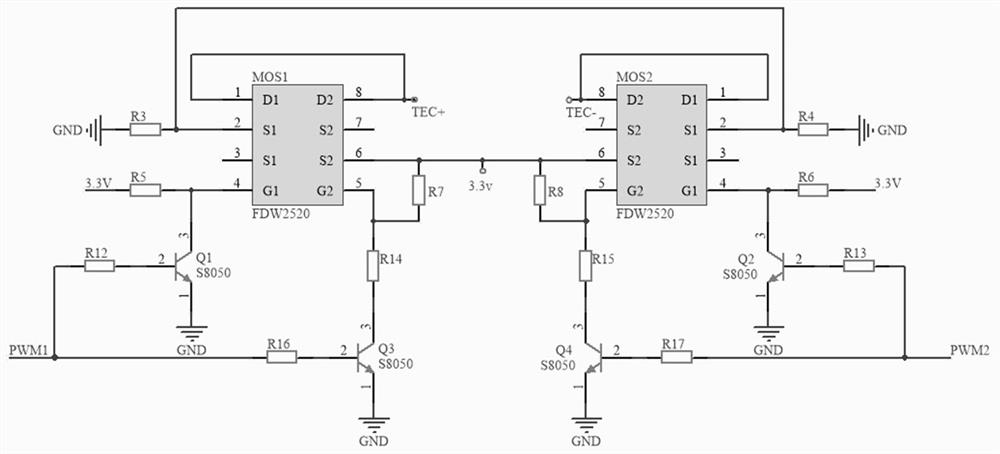

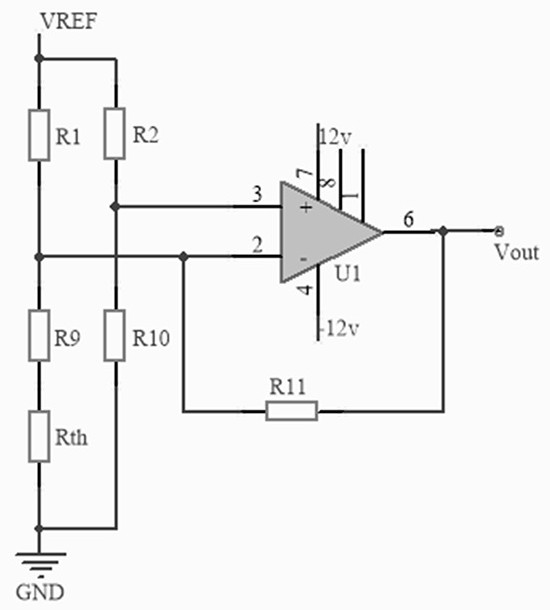

[0018] Such as Figure 1~4 As shown, the present invention discloses a high-precision and high-stable temperature control system for chaotic semiconductor lasers, including a microcontroller module, a semiconductor cooling chip, an H-bridge drive module for driving the semiconductor cooling chip, and a temperature feedback laser temperature change The feedback module and the analog-to-digital conversion module that detects the output voltage of the temperature feedback module. The microcontroller is a 32-bit microcontroller STM32F407 from STMicroelectronics. The microcontroller receives the output signal of the analog-to-digital conversion module, and the temperature fed back by the temperature feedback module Compared with the set temperature, the difference obtained is sent to the fuzzy PID algorithm, and the high-speed control area and the fuzzy control ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com