A kind of chlorine-free water film-forming foam fire extinguishing agent and preparation method thereof

A foam fire extinguishing agent and film-forming technology, applied in fire prevention equipment, etc., can solve the problems of storage tank corrosion, high corrosion, environmental pollution, etc., and achieve low equipment corrosion, good recombustion resistance, and good spreading performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

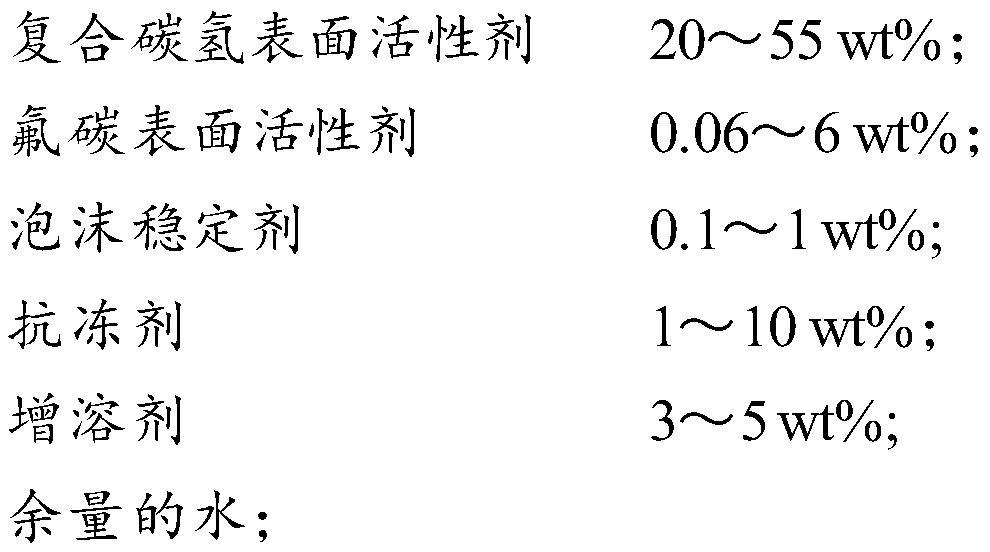

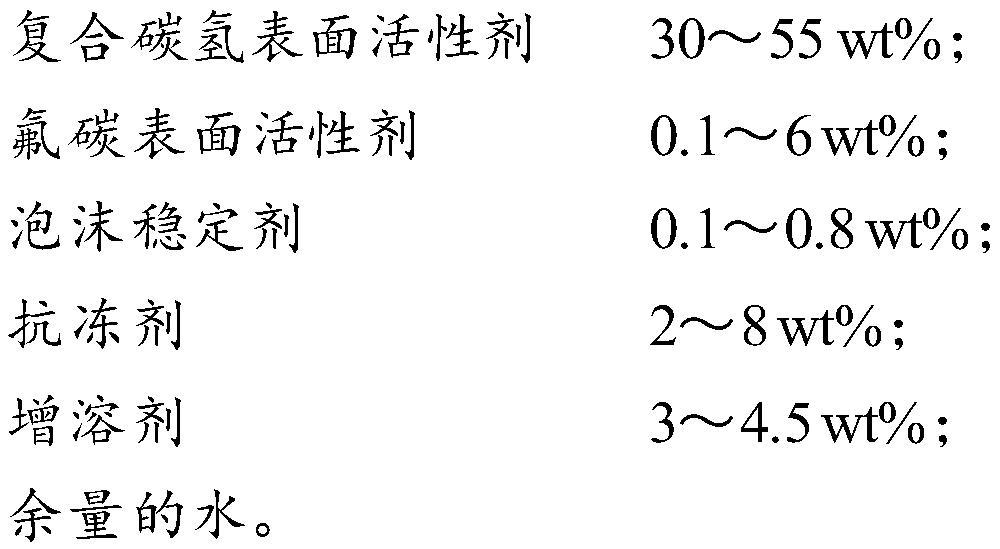

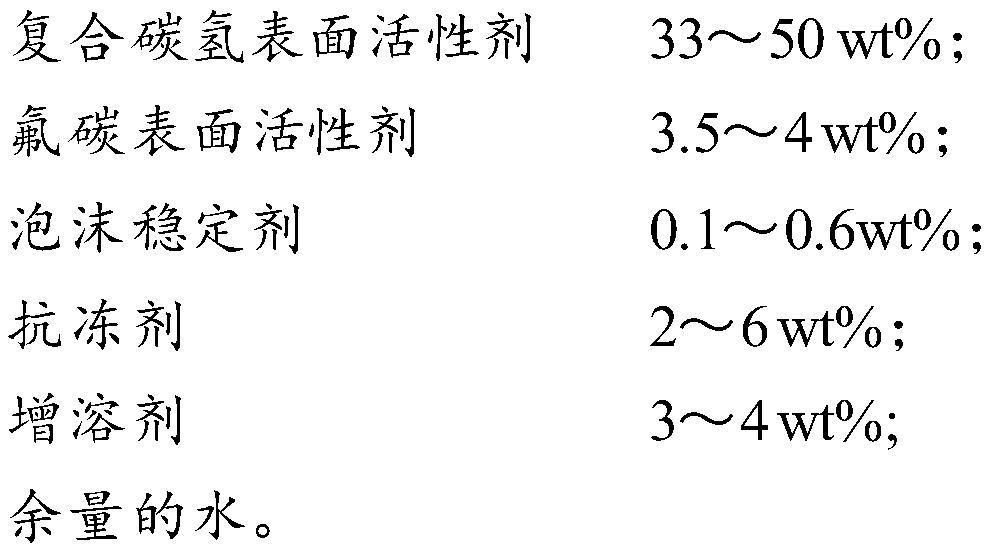

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the above-mentioned chlorine-free water film-forming foam fire extinguishing agent, comprising: after mixing the foam stabilizer with water, adding composite hydrocarbon surfactant, fluorocarbon surfactant, antifreeze and The solubilizers are mixed to obtain the chlorine-free water film-forming foam fire extinguishing agent.

[0043] Wherein, the present invention has no special limitation on the source of all raw materials. The composite hydrocarbon surfactant, fluorocarbon surfactant, foam stabilizer, antifreeze agent and solubilizer are all the same as above, and will not be repeated here.

[0044] The alkyl alcohol sulfate surfactant in the composite hydrocarbon surfactant of the present invention is the product produced with alkali neutralization after the alkanol alcohol is through sulfation; Glycoside surfactant adopts direct glycosidation method Production. The content of chloride ions in the raw mate...

Embodiment 1

[0050] Embodiment 1 (6%AFFF product)

[0051] Under normal temperature and pressure, first add 0.1kg of sodium alginate and 58.4kg of water into the reaction kettle to fully stir and pre-dissolve, then weigh long-chain alkyl alcohol sulfate (K 10 ) 25kg, short carbon chain alkyl alcohol sulfate (SOS) 5kg, alkyl glycoside (APG0814) 3kg, anionic fluorocarbon surfactant (FS-6201) 3.5kg, ethylene glycol 2kg, urea 3kg, add to the reaction kettle Thoroughly stir and mix to obtain about 100kg of chlorine-free aqueous film-forming foam fire extinguishing agent product.

Embodiment 2

[0053] Under normal temperature and pressure, first add 0.1kg of sodium alginate and 58.4kg of water into the reaction kettle to fully stir and pre-dissolve, then weigh long-chain alkyl alcohol sulfate (K 10 ) 5kg, short carbon chain alkyl alcohol sulfate (SOS) 25kg, alkyl glycoside (APG0814) 3kg, anionic fluorocarbon surfactant (FS-6201) 3.5kg, ethylene glycol 2kg, urea 3kg, add to the reaction kettle Thoroughly stir and mix to obtain about 100kg of chlorine-free aqueous film-forming foam fire extinguishing agent product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com