Laser welding gas protection and dedusting device, welding method and control system

A gas shielding and laser welding technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of insufficient isolation, increased production cost of enterprises, poor welding quality of products, etc., to ensure welding quality and improve yield rate , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

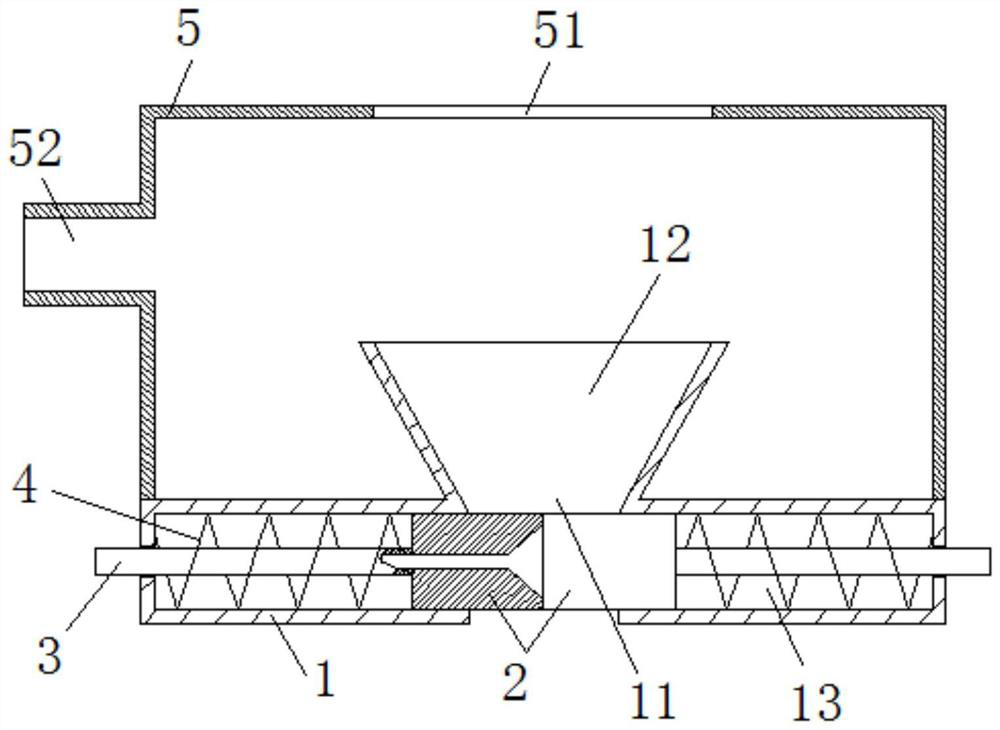

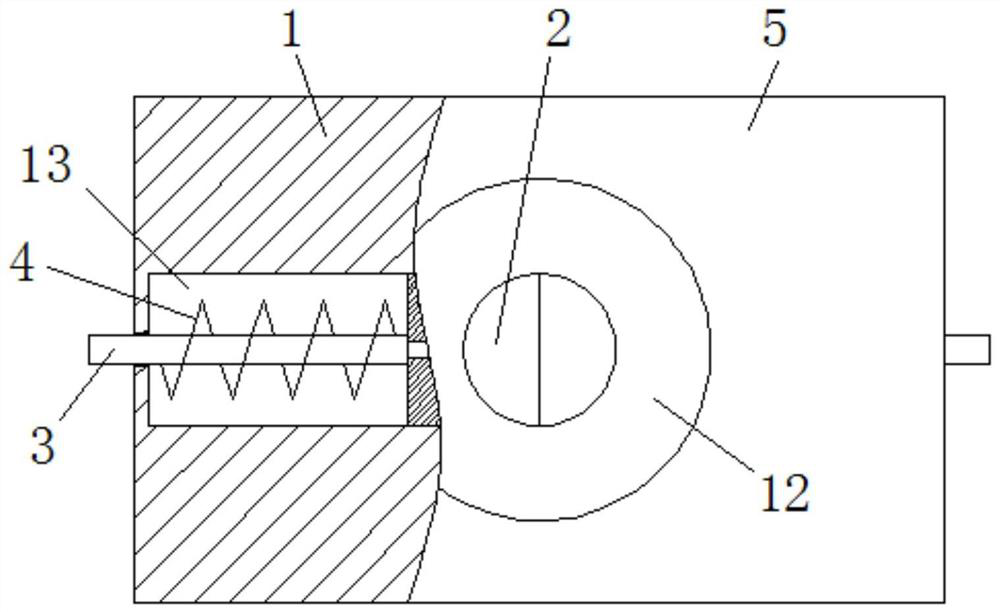

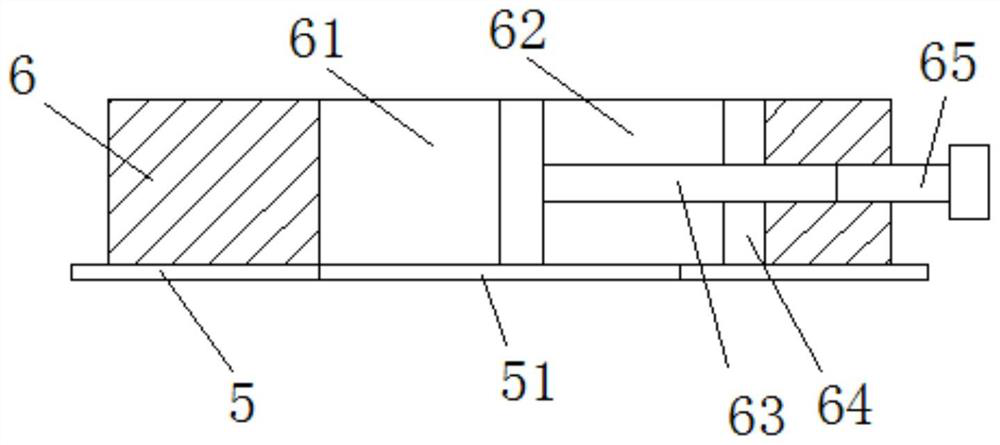

[0048] Such as figure 1 and figure 2 The shown optional embodiment of the gas protection and dust removal device for laser welding includes a base 1, a dust cover 5, two sliders 2, a gas supply pipe 3 and a first spring 4, wherein

[0049] Described base 1 comprises welding hole 11, laser beam channel 12 and chute 13, and described laser beam channel 12 is arranged on the upper end of welding hole 11, and described chute 13 is arranged symmetrically on both sides of welding hole 11, and described chute 13 setting the first spring 4;

[0050] The two sliders 2 are respectively installed in the chute 13 on both sides of the welding hole 11, and the two sliders 2 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap