Steel pipe annular welding device with welding seam detection function

A welding seam detection and ring welding technology, applied in the field of steel pipe welding, can solve the problems of difficult to meet the steel pipe welding, difficult work, complicated operation, etc., and achieve the effect of realizing internal and external synchronous detection, improving rotation stability, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

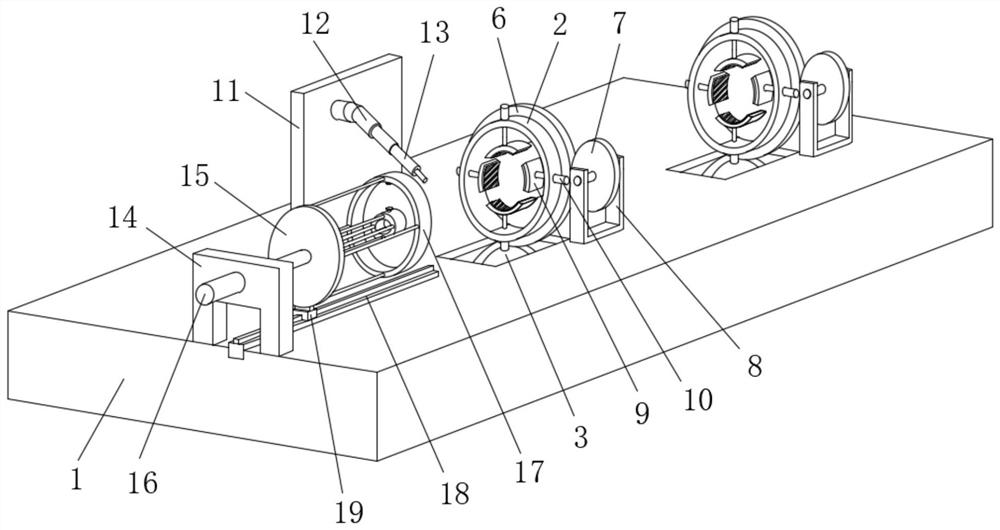

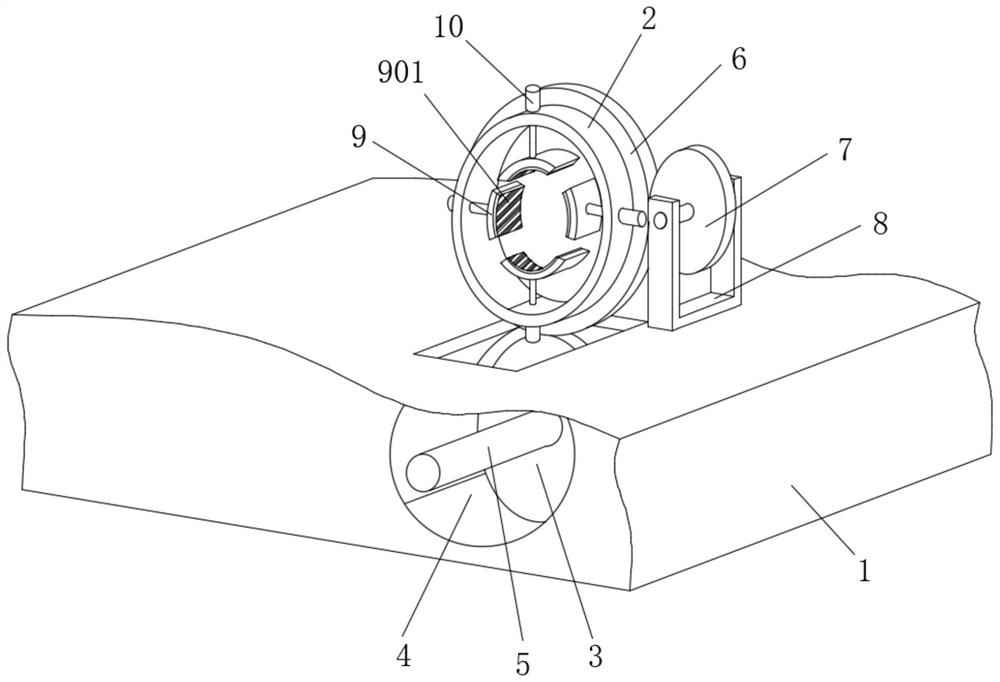

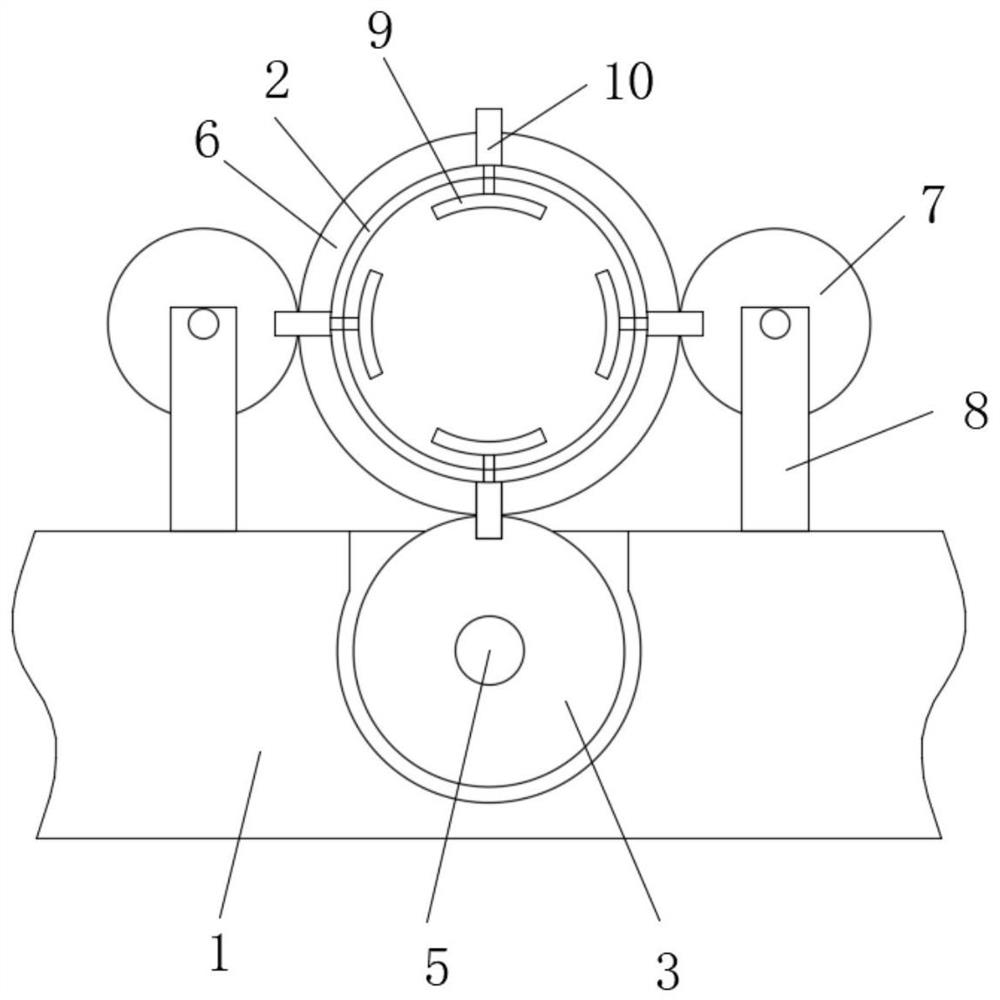

[0035] see Figure 1-3 and Figure 5, a circular welding device for steel pipes with a weld seam detection function, including a console 1 and a pair of limit mechanisms installed on the front and rear ends of the console 1, the limit mechanisms realize the clamping and positioning of steel pipes, the interior of the console 1 There is a pair of arc-shaped cavities 4 corresponding to the position of the limit mechanism, the tops of the pair of arc-shaped cavities 4 penetrate to the upper end of the console 1, and the drive gears 3 are installed in the pair of arc-shaped cavities 4 for rotation. The two drive gears 3 are rotationally connected by the rotating shaft 5, and one end of the console 1 is fixedly installed with a rotating motor that drives the rotating shaft 5, and those skilled in the art select a suitable type of motor for installation, and the rotating motor drives the rotating shaft 5 to rotate , so that the two driven gears 6 are driven to rotate by the two dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com