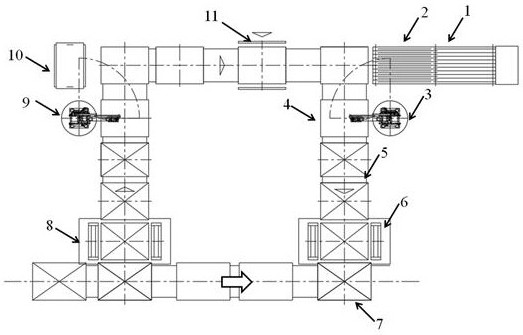

Wet green brick stacking and dry green brick unloading production line and method for single-layer drying of sintered bricks

A single-layer drying and sintering brick technology, which is applied in the direction of drying solid materials, drying chambers/containers, and dry goods handling, etc., can solve the problems of limited output of lifting platform lifting frequency, high equipment complexity, high equipment cost, etc., and achieve simple structure , a single action, the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] When the adobe is formed, the material is extruded by a double-stage vacuum extruder into a mud strip with a smooth surface and a dense interior. The extruded mud strip is cut into the brick adobe of the required size by a strip cutter and a blank cutter, and then grouped by wet billets The differential speed of the platform and the belt will open the gap between the adobes and divide them, arrange the adobe groups arranged in the slits into a square array of the size of a single-layer drying car pallet, and put the whole square array on the pallet through the manipulator according to the grabbing and turning 90 degrees On the top, the trays that arrange the wet bricks into a neat array are supported by chains or synchronous belts, and the trays carrying the bricks are sent to the single-layer drying car through the tray conveyor and automatic telescopic device, and are lifted and lowered by chains and positioned by guide rails. The drying tray lifting equipment will loa...

Embodiment 2

[0050] When the green body is formed, the material is extruded by a double-stage vacuum extruder to form a smooth surface and a dense inner clay bar. The extruded mud bar is cut into bricks of the required size by a strip cutter and a blank cutter, and then passed through a wet billet. The marshalling table and the differential speed of the belt will open the gap between the adobes and divide them, arrange the adobe groups arranged in the slits into a square array of the size of a single-layer drying car tray, and pass the frequency-converted neat adobe square array through the front and rear independently. The moving green body platform is sent into one of the layers of the drying car. According to the control system instructions, the platform loaded with the green body runs in the direction of returning after reaching the set position. Slowly shrink back, the green body is slowly put on the drying car, and the ferry car will send the drying car to the working position that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com