Glass preparation method and photovoltaic glass plate

A glass plate and glass technology, applied in glass manufacturing equipment, photovoltaic power generation, glass molding, etc., can solve problems such as the limitation of solar cell application scenarios, achieve excellent visible light transmittance, reduce thermal conductivity, and the preparation method is simple and controllable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention are illustrated below through specific examples.

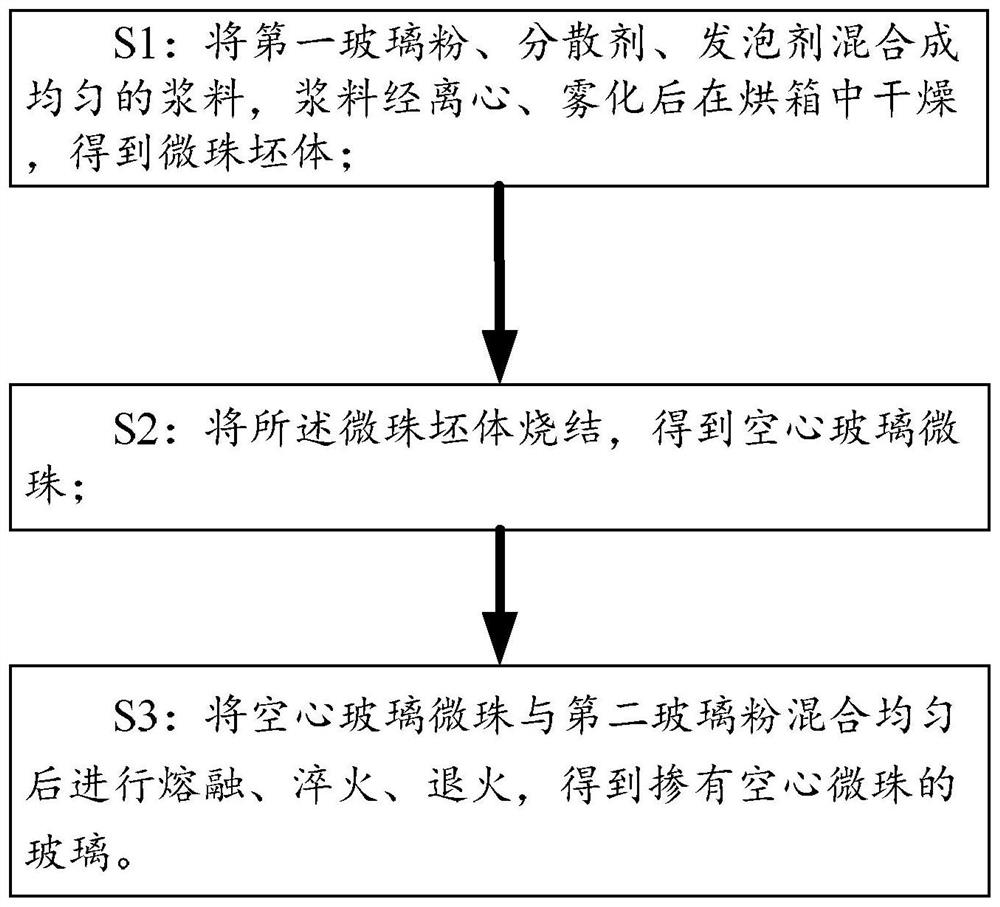

[0026] Such as figure 1 as shown, figure 1 A schematic diagram showing the method of the present invention for preparing cenosphere-doped glass. The method includes the following steps:

[0027] S1: Mix the first glass powder, dispersant, and foaming agent into a uniform slurry, and dry the slurry in an oven after centrifugation and atomization to obtain a glass bead green body;

[0028] In step S1, the first glass frit is used as the raw material of the glass matrix, which needs to have the property of high temperature resistance. Generally, the first glass frit needs to have a melting temperature of 1600° C. or higher. The first glass powder is a commercial product and is available on the market.

[0029] In step S1, there is no special requirement for the dispersant, it only needs to be able to disperse the first glass powder uniformly. As an example, the dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com