Preparation method of graphene lubricating oil for vehicles

A graphene and lubricating oil technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve problems such as difficulty in starting, poor lubricating oil fluidity, poor low temperature fluidity, etc. The effect of flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

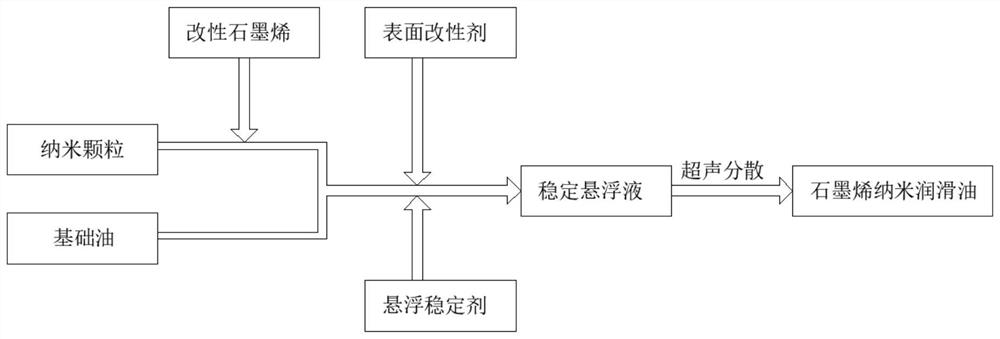

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of graphene lubricating oil for vehicles, comprising the following preparation steps:

[0022] (1) Modification of graphene: first prepare an acidic mixed solution according to the following parts by volume, mix 4 parts of sorbitan fatty acid esters, 5 parts of methacrylic acid and 10 parts of boric acid, stir and mix for 40 minutes at 50 ° C, to obtain The acidic mixed solution is then cooled to normal temperature, then added to dehydrated alcohol 5 times its weight, stirred evenly, graphene, calcium linoleate, and methyl linolenate are added to the above mixed solution, and the temperature is raised to 75°C, keep warm and stir for 2.5h, stir evenly, spin evaporate, remove ethanol to obtain sample liquid, then use high-purity deionized water to wash the sample liquid, filter, and dry to obtain modified graphene;

[0023] (2) Preparation of nano-lubricating oil: use the second-class base oil 150N without additives as the base oil liquid, add nano-Si...

Embodiment 2

[0032] A preparation method of graphene lubricating oil for vehicles, comprising the following preparation steps:

[0033] (1) Modification of graphene: first prepare an acidic mixed solution according to the following parts by volume, mix 5 parts of sorbitan fatty acid esters, 7 parts of methacrylic acid and 12 parts of boric acid, stir and mix at 56 ° C for 35 min to obtain The acidic mixed solution is then cooled to normal temperature, then added to 5.5 times of its weight in absolute ethanol, stirred evenly, graphene, calcium linoleate, and methyl linolenate are added to the above mixed solution, and the temperature is raised to 78°C, heat preservation and stirring for 2.5 hours, stir evenly, rotary steaming, remove ethanol to obtain a sample liquid, and then use high-purity deionized water to wash the sample liquid, filter, and dry to obtain modified graphene;

[0034] (2) Preparation of nano-lubricating oil: use the second-class base oil 150N without additives as the bas...

Embodiment 3

[0043] A preparation method of graphene lubricating oil for vehicles, comprising the following preparation steps:

[0044](1) Modification of graphene: first prepare an acidic mixed solution according to the following parts by volume, mix 6 parts of sorbitan fatty acid esters, 8 parts of methacrylic acid and 15 parts of boric acid, stir and mix at 60 ° C for 30 min, to obtain The acidic mixed solution is then cooled to normal temperature, then added to 6 times its weight in absolute ethanol, stirred evenly, graphene, calcium linoleate, and methyl linolenate are added to the above mixed solution, and the temperature is raised to 80°C, heat preservation and stirring for 2.5 hours, stir evenly, rotary steaming, remove ethanol to obtain a sample liquid, and then use high-purity deionized water to wash the sample liquid, filter, and dry to obtain modified graphene;

[0045] (2) Preparation of nano-lubricating oil: use the second-class base oil 150N without additives as the base oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com