Processing technology of functional nano regenerated fiber

A technology of regenerated fiber and processing technology, applied in the field of textiles, can solve the problems of the influence of additives, the difficulty of endowing regenerated fiber with functionality, and the difficulty of stabilizing the processing quality, etc., to achieve excellent functional effect, good antibacterial performance and anti-ultraviolet performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in combination with specific embodiments.

[0025] In the following examples, the regenerated fiber used for preparation is viscose fabric, 87.9g / m 2 , do not need to change the chemical fiber spinning process.

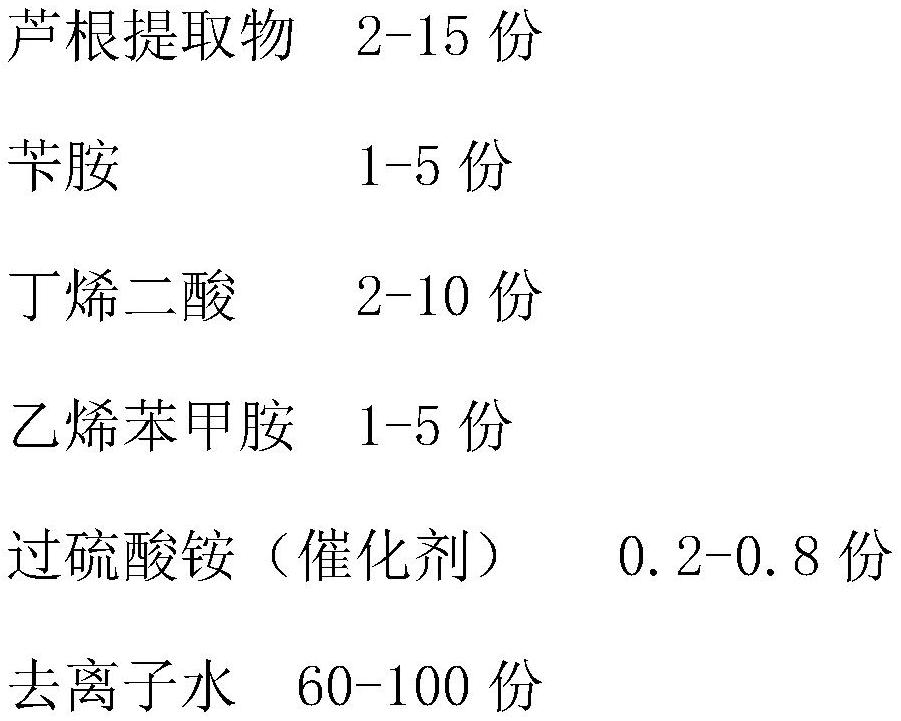

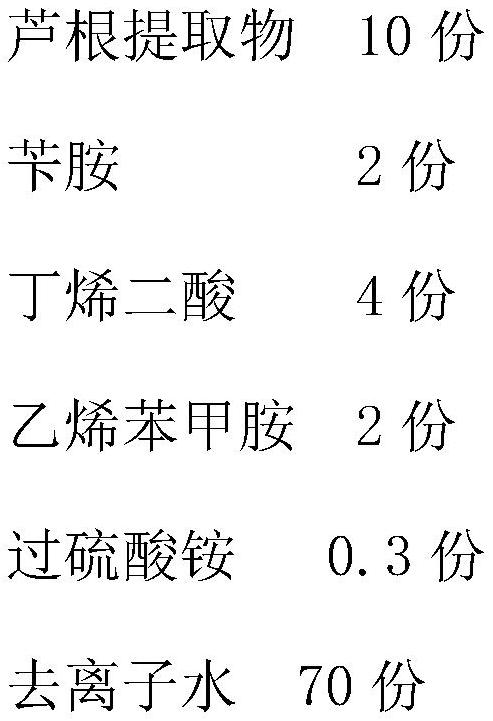

[0026] One, the added nano-functional agent component of embodiment 1-4 is as shown in table 1 (unit: weight part):

[0027] Table 1

[0028] Example 1 Example 2 Example 3 Example 4 Reed root extract (parts) 10 15 2 6 Benzylamine (parts) 2 5 1 3 Butenedioic acid (parts) 4 10 2 6 Vinylbenzylamine (parts) 2 5 1 3 Ammonium persulfate (part) 0.3 0.8 0.2 0.4 Deionized water (parts) 70 100 60 80

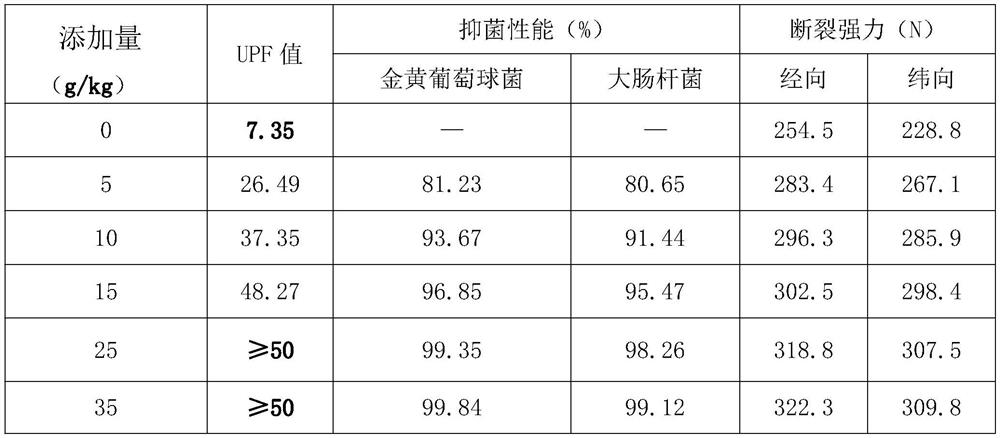

[0029] 2. Investigate the influence of different nano-functional agent additions

[0030] The amount of nano-functional agent added is 0-35g / kg (and greater than 0), and the regenerated fibers obtained by different additions of nano-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com