Cold-resistant data transmission cable

A data transmission cable, cold-resistant technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve problems such as pull-off, sheath cracking, flattening, etc., achieve round structure, reduce maintenance costs, and excellent low-temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

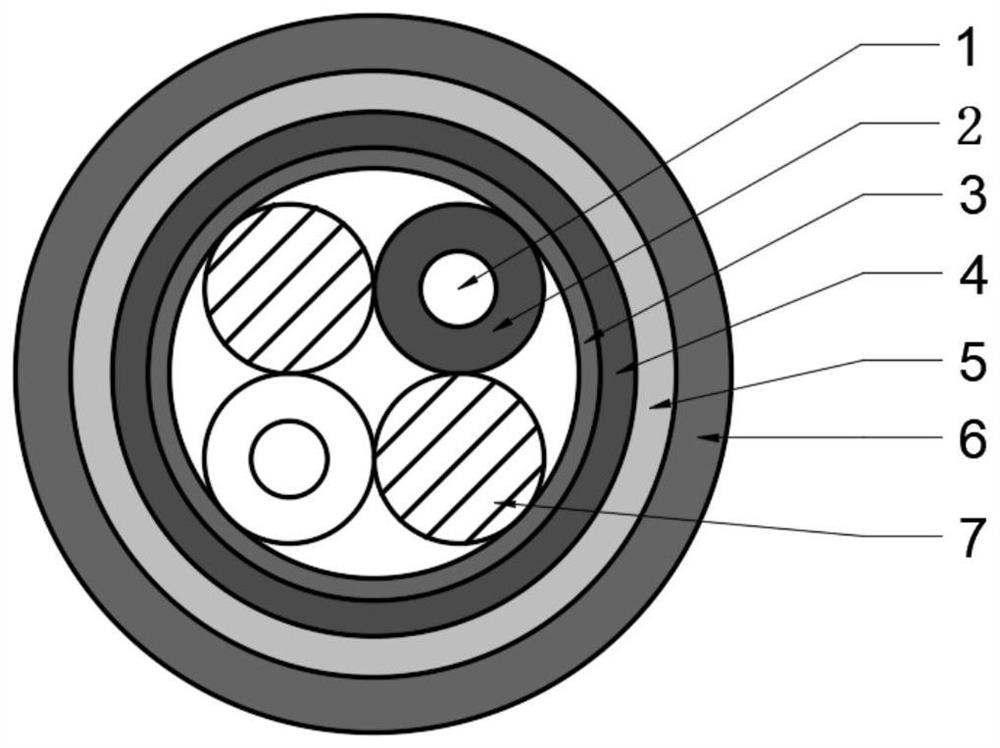

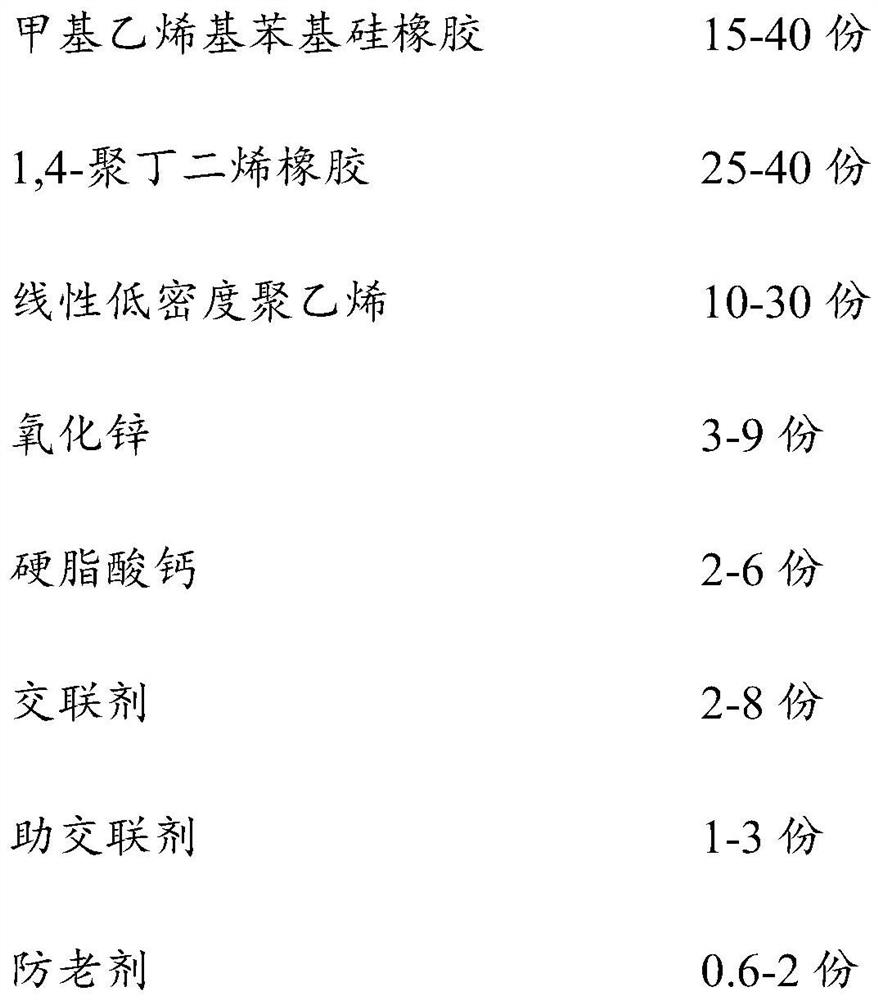

[0039] see figure 1 , this embodiment provides a cold-resistant data transmission cable, including a cable core composed of a stranded copper conductor 1 and a filling rope 7, a cold-resistant tape layer 3 wrapped on the outside of the cable core in turn, a cold-resistant inner sheath layer 4, copper Silk braiding layer 5 and cold-resistant outer sheath 6; wherein, the surface of the stranded copper conductor 1 is provided with an insulating layer 2, the cold-resistant tape layer 3 is a PE film, and the raw materials of the cold-resistant inner sheath layer 4 and the cold-resistant outer sheath 6 include: The following components in parts:

[0040]

[0041]

[0042] Wherein, the phenyl content in the methyl vinyl phenyl silicone rubber is 5-10%.

[0043] The preparation process of the above-mentioned cold-resistant inner sheath layer and cold-resistant outer sheath raw materials is as follows:

[0044] Use a silane coupling agent to couple silica and magnesium hydroxide,...

Embodiment 2

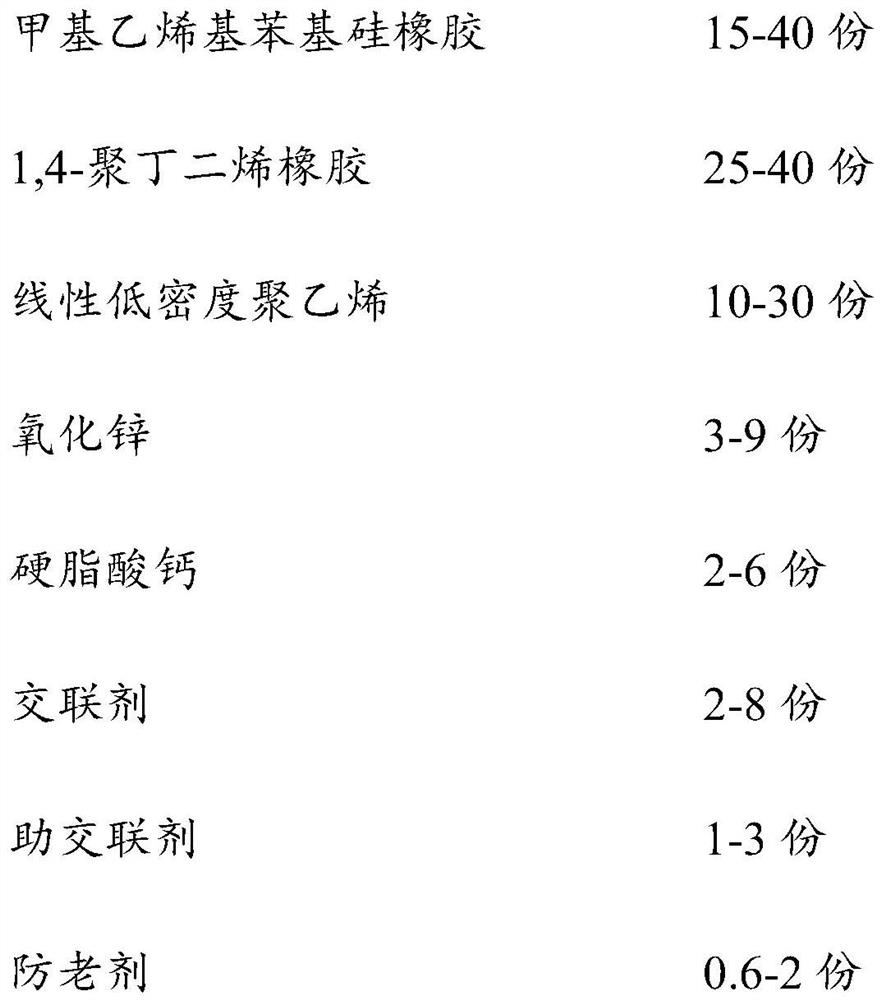

[0046] This embodiment provides a cold-resistant data transmission cable, which includes a cable core composed of a stranded copper conductor and a filling rope, a cold-resistant tape layer wrapped on the outside of the cable core, a cold-resistant inner sheath, a copper wire braid, and a cold-resistant Outer sheath; wherein, the surface of the stranded copper conductor is provided with an insulating layer, the cold-resistant tape layer is a PP film, and the raw materials for the cold-resistant inner sheath layer and the cold-resistant outer sheath include the following components by weight:

[0047]

[0048] Wherein, the phenyl content in the methyl vinyl phenyl silicone rubber is 5-10%.

[0049] The preparation process of the above-mentioned cold-resistant inner sheath layer and cold-resistant outer sheath raw materials is as follows:

[0050] Use a silane coupling agent to couple silica and magnesium hydroxide, then add the coupled silica and magnesium hydroxide together...

Embodiment 3

[0052] This embodiment provides a cold-resistant data transmission cable, which includes a cable core composed of a stranded copper conductor and a filling rope, a cold-resistant tape layer wrapped on the outside of the cable core, a cold-resistant inner sheath, a copper wire braid, and a cold-resistant Outer sheath; wherein, the surface of the stranded copper conductor is provided with an insulating layer, the cold-resistant tape layer is a PU film, and the raw materials for the cold-resistant inner sheath layer and the cold-resistant outer sheath include the following components by weight:

[0053]

[0054] Wherein, the phenyl content in the methyl vinyl phenyl silicone rubber is 5-10%.

[0055] The preparation process of the above-mentioned cold-resistant inner sheath layer and cold-resistant outer sheath raw materials is as follows:

[0056] Use a silane coupling agent to couple silica and magnesium hydroxide, then add the coupled silica and magnesium hydroxide together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com