Preparation method and application of composite zinc isooctanoate

A technology of zinc isooctanoate and sulfuric acid, which is applied in the direction of carboxylate preparation, carboxylate preparation, organic compound preparation, etc., to achieve the effect of good use effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

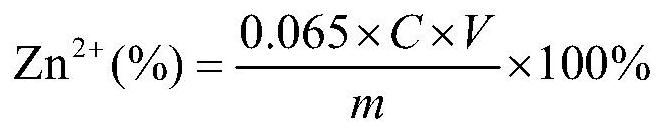

Image

Examples

preparation example Construction

[0025] In an embodiment, the preparation method of the complex zinc isooctanoate comprises the following steps:

[0026] (1) Get mass concentration and be that the sulfuric acid 200-300ml of 32-40% is put in the reactor, add zinc oxide 17.4-19.3g, succinic anhydride 28.4-34.2g, be 300-500r / min to stir with rotating speed, in Heat to a temperature of 70-78°C with a microwave power of 200-300W, then keep the temperature at 70-78°C, increase the microwave power of 400-600W and react for 1-1.5h to prepare a mixed solution A;

[0027] (2) Add 36.2-38g of isooctanoic acid to the mixed solution A prepared in step (1), heat it to a temperature of 128-135°C at a microwave power of 300-400W, then keep the temperature at 128-135°C, and microwave power React at 300-400W for 2-3h to prepare mixed solution B;

[0028] (3) The mixed solution B that step (2) is made is transferred to carry out decompression reaction and reclaim succinic acid in the decompression reactor, then reclaim sulfuri...

Embodiment 1

[0030] A preparation method of compound zinc isooctanoate, comprising the following steps:

[0031] (1) Take 300ml of sulfuric acid with a mass concentration of 33.4% and put it in a reaction kettle, add 17.8g of zinc oxide and 29.3g of succinic anhydride, stir at a speed of 300r / min, and heat to a temperature of 72 ℃, then keep the temperature at 72 ℃, increase the microwave power to 400W and react for 1.5h to prepare the mixed solution A;

[0032] (2) in the mixed solution A that step (1) makes, add the 36.4g isooctanoic acid that mass concentration is 99.5%, be that 130 ℃ are heated to temperature under microwave power under 300W, then keep temperature and be 130 ℃, microwave power is Reaction at 300W for 3h to prepare mixed solution B;

[0033] (3) the mixed solution B that step (2) is made is transferred to carry out decompression reaction and reclaim succinic acid in the decompression reactor, then reclaim sulfuric acid, make compound zinc isooctanoate, viscosity 14000m...

Embodiment 2

[0035] A preparation method of compound zinc isooctanoate, comprising the following steps:

[0036] (1) Put 260ml of sulfuric acid with a mass concentration of 36.8% in a reaction kettle, add 18.6g of zinc oxide and 31.7g of succinic anhydride, stir at a speed of 400r / min, and heat to a temperature of 75 °C, then keep the temperature at 75 °C, increase the microwave power to 500W and react for 1.3h to prepare the mixed solution A;

[0037] (2) Adding 37g of isooctanoic acid with a mass concentration of 99.5% to the mixed solution A prepared in step (1), heating to a temperature of 132° C. at a microwave power of 400 W, then keeping the temperature at 132° C., and a microwave power of 400 W Down reaction 2.2h, make mixed solution B;

[0038] (3) the mixed solution B that step (2) is made is transferred to carry out decompression reaction and reclaim succinic acid in the decompression reactor, then reclaim sulfuric acid, make compound zinc isooctanoate, viscosity 11600mPa s, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com