A swinging electromagnetic induction power generation flexible fabric and its production method and application

A flexible fabric and electromagnetic induction technology, applied in fabrics, textiles, layered products, etc., can solve problems such as poor user experience, poor softness, and difficulty in making fabrics, and achieve stable and controllable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a production method of a swing electromagnetic induction power generation flexible fabric, including a production method of a magnetic yarn fabric and a production method of a conductive coil fabric.

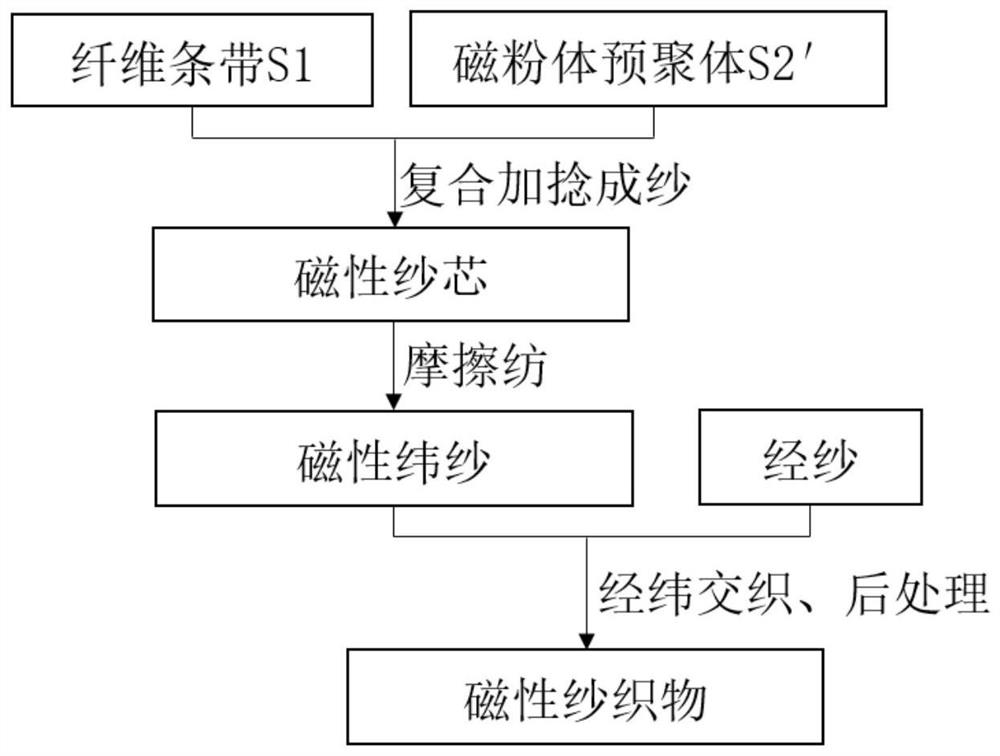

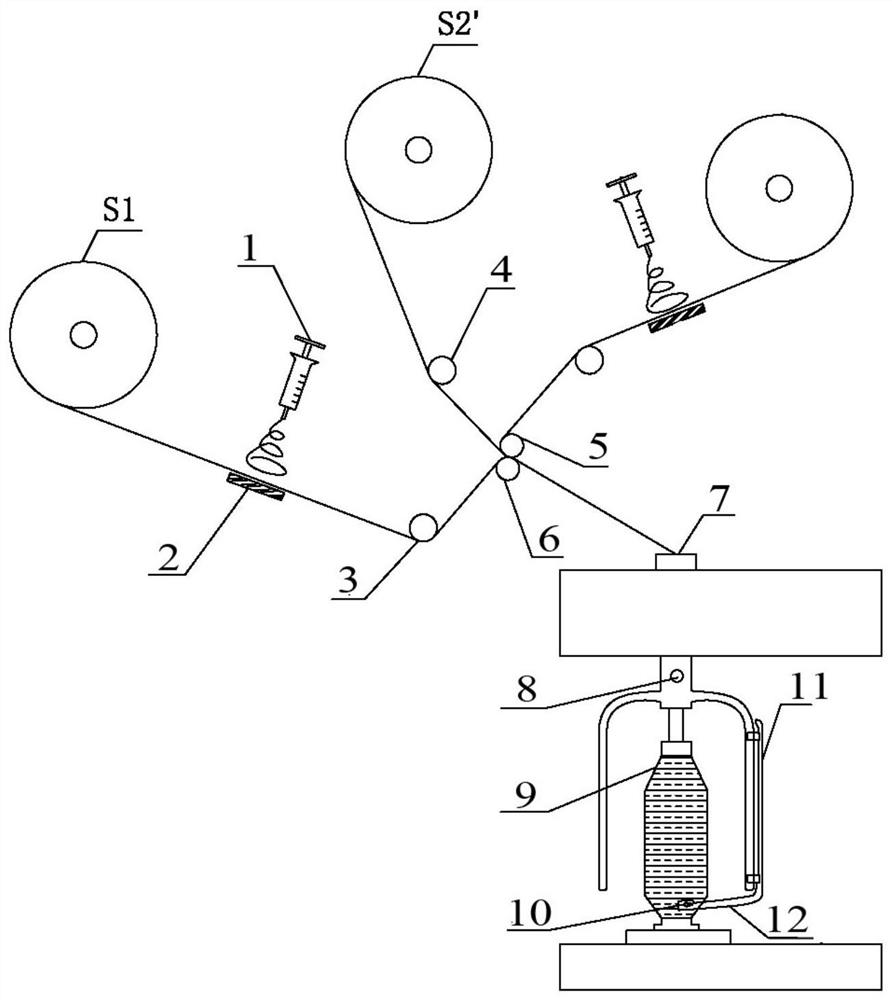

[0041] The production method of described magnetic yarn fabric is as figure 1 As shown, it specifically includes the following steps:

[0042] A1, preparation of fiber strip S1

[0043] Set the areal density to 20g / m 2 The non-woven flexible surface material roll is installed on a cutting machine, cut into fiber strips S1 with a linear density of 100g / km, and then wound on a bobbin to obtain a fiber strip S1 package.

[0044] A2. Preparation of magnetic powder prepolymer S2'

[0045] The magnetic powder is demagnetized, and the surface density is 20g / m 2 Adhesive tape S2 rolls are installed at the rear end of the padding machine, after peeling off the anti-sticking strip on the surface of the adhesive tape S2, the remaining adhesive tape is im...

Embodiment 2~3

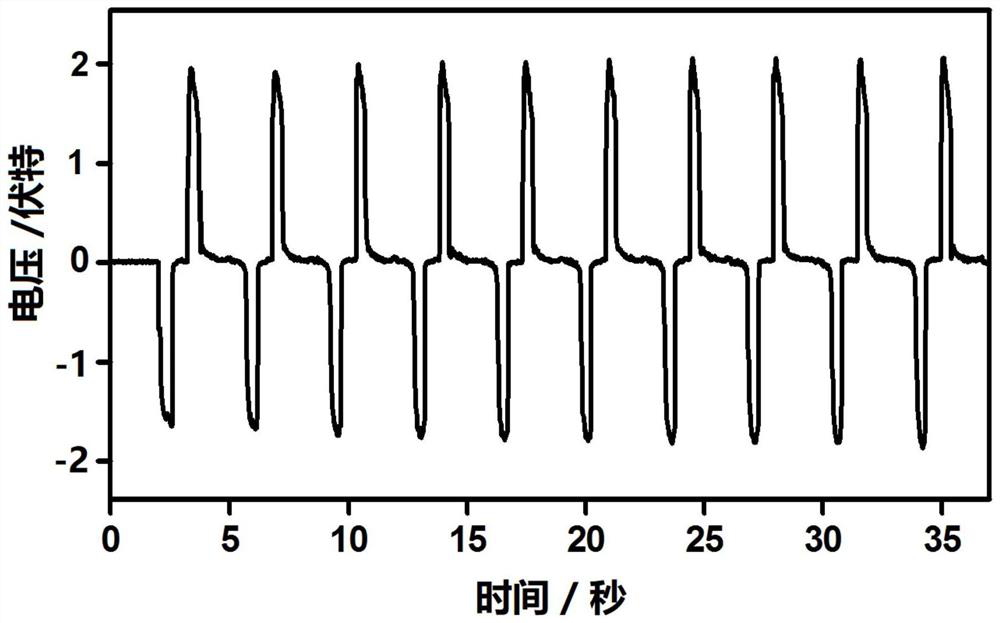

[0065] Embodiments 2 to 3 respectively provide an application of a swinging electromagnetic induction generating flexible fabric. Among them, in Example 2, the swinging electromagnetic induction type power generation flexible fabric produced in Example 1 is applied to the power generation top, and its structural diagram is as follows Figure 4 shown; embodiment 3 then applies the swing electromagnetic induction type power generation flexible fabric produced in embodiment 1 to power generation pants, and its structural schematic diagram is as follows Figure 5 shown.

[0066] Depend on Figure 4 It can be seen that in Example 2, when the oscillating electromagnetic induction type power generation flexible fabric produced in Example 1 is applied to the power generation upper garment, the magnetic yarn fabric is sewn on the side of the garment body of the upper garment, and the conductive coil fabric is sewn on the garment body On the inner side of the sleeve with opposite side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com