Nano material, synthesis method thereof, gas sensor and preparation method and application of gas sensor

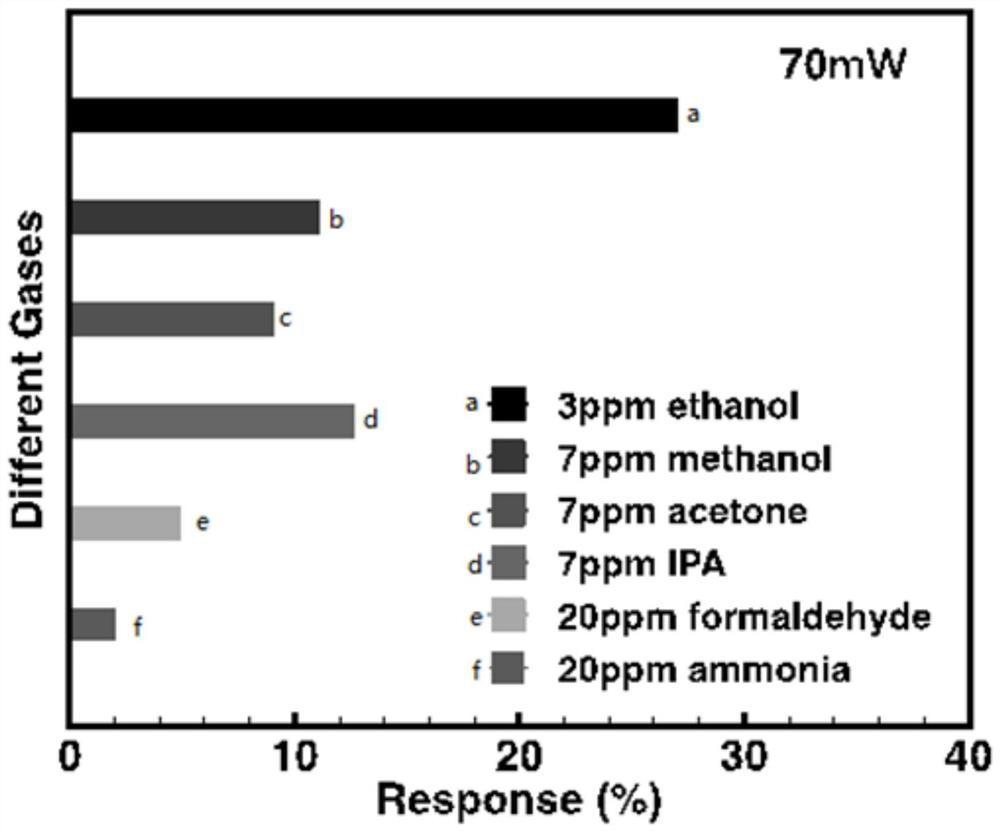

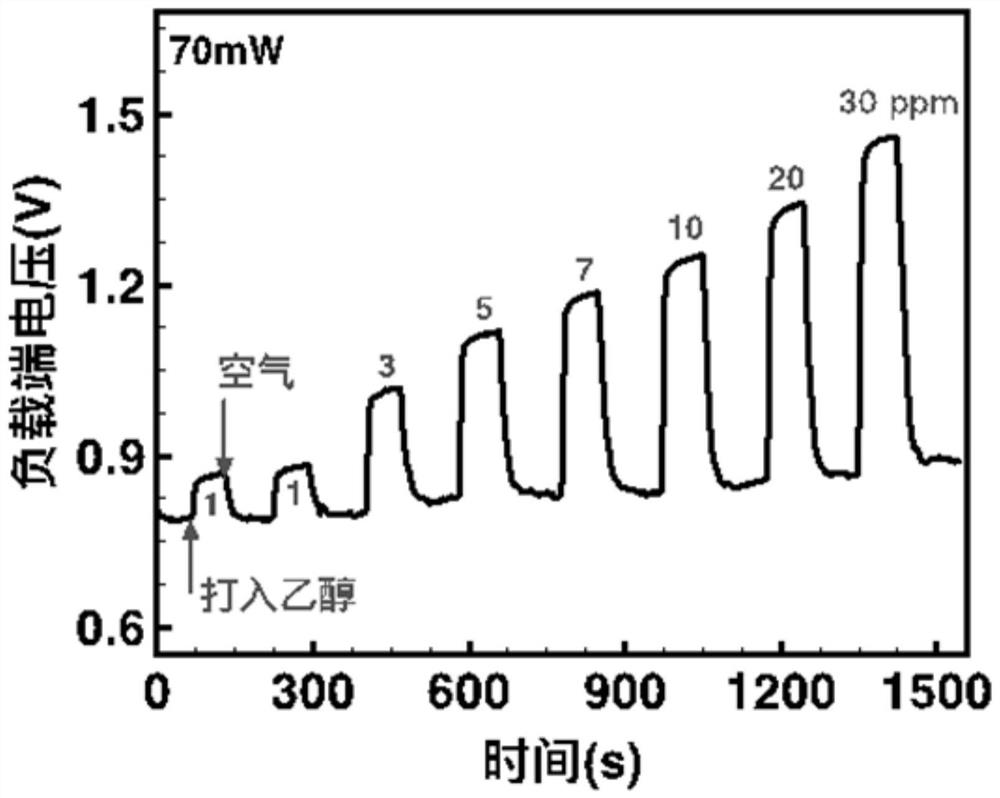

A gas sensor and nanomaterial technology, applied in the field of sensors, can solve the problems of poor selectivity and repeatability, and achieve the effects of low manufacturing cost, good gas sensitivity characteristics, good selectivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a kind of synthetic method of nanometer material, it comprises the following steps:

[0035] S1. Dissolve 0.5mmol of ferric nitrate nonahydrate, 0.4g of polyvinylpyrrolidone and 0.554g of sodium acetate (4mmol) in 30mL of a mixed solvent, and then place it in a reaction kettle at 180°C for 24 hours of hydrothermal reaction. get reactants. Wherein, the mixed solvent is formed by mixing methanol and deionized water according to a volume ratio of 1:2.

[0036] S2. Suction filtration and separation of the above-mentioned reactant to obtain a solid.

[0037] S3. Wash the above-mentioned solid matter with absolute ethanol and deionized water three times in sequence, and dry it at 80°C for 6 hours, and then place it in a muffle furnace at 450°C for calcination for 3 hours to obtain a rhombohedral structure Fe 2 o 3 nanomaterials. Wherein, the heating rate of the muffle furnace is 5° C. / min.

Embodiment 2

[0039] This embodiment provides a kind of synthetic method of nanometer material, it comprises the following steps:

[0040] S1. Dissolve 0.5mmol of ferric nitrate nonahydrate, 0.2g of polyvinylpyrrolidone and 0.554g of sodium acetate (4mmol) in 30mL of mixed solvent, and then place it in a reaction kettle at 180°C for 30h of hydrothermal reaction. get reactants. Wherein, the mixed solvent is formed by mixing methanol and deionized water according to a volume ratio of 1:2.

[0041] S2. Suction filtration and separation of the above-mentioned reactant to obtain a solid.

[0042] S3. Wash the above-mentioned solid matter with absolute ethanol and deionized water three times in sequence, and dry it at 80°C for 6 hours, and then place it in a muffle furnace at 450°C for calcination for 3 hours to obtain a rhombohedral structure Fe 2 o 3 nanomaterials. Wherein, the heating rate of the muffle furnace is 5° C. / min.

Embodiment 3

[0044] This embodiment provides a kind of synthetic method of nanometer material, it comprises the following steps:

[0045] S1. Dissolve 0.5mmol of ferric nitrate nonahydrate, 0.4g of polyvinylpyrrolidone and 0.554g of sodium acetate (4mmol) in 30mL of mixed solvent, and then place it in a reaction kettle at 180°C for 30h of hydrothermal reaction. get reactants. Wherein, the mixed solvent is formed by mixing methanol and deionized water according to a volume ratio of 1:2.

[0046] S2. Suction filtration and separation of the above-mentioned reactant to obtain a solid.

[0047] S3. Wash the above-mentioned solid matter with absolute ethanol and deionized water three times in sequence, and dry it at 80°C for 6 hours, and then place it in a muffle furnace at 500°C for calcination for 3 hours to obtain a rhombohedral structure Fe 2 o 3 nanomaterials. Wherein, the heating rate of the muffle furnace is 5° C. / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com