Pantoprazole sodium freeze-drying preparation, preparation method thereof, and injection preparation prepared from pantoprazole sodium freeze-drying preparation

A technology for pantoprazole sodium and freeze-dried preparations, which is applied in the field of pharmaceutical preparations, can solve the problems of long freeze-drying time and instability of pantoprazole sodium freeze-dried preparations, and achieve stable product quality, clarity and color stability , Improving the effect of molding and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

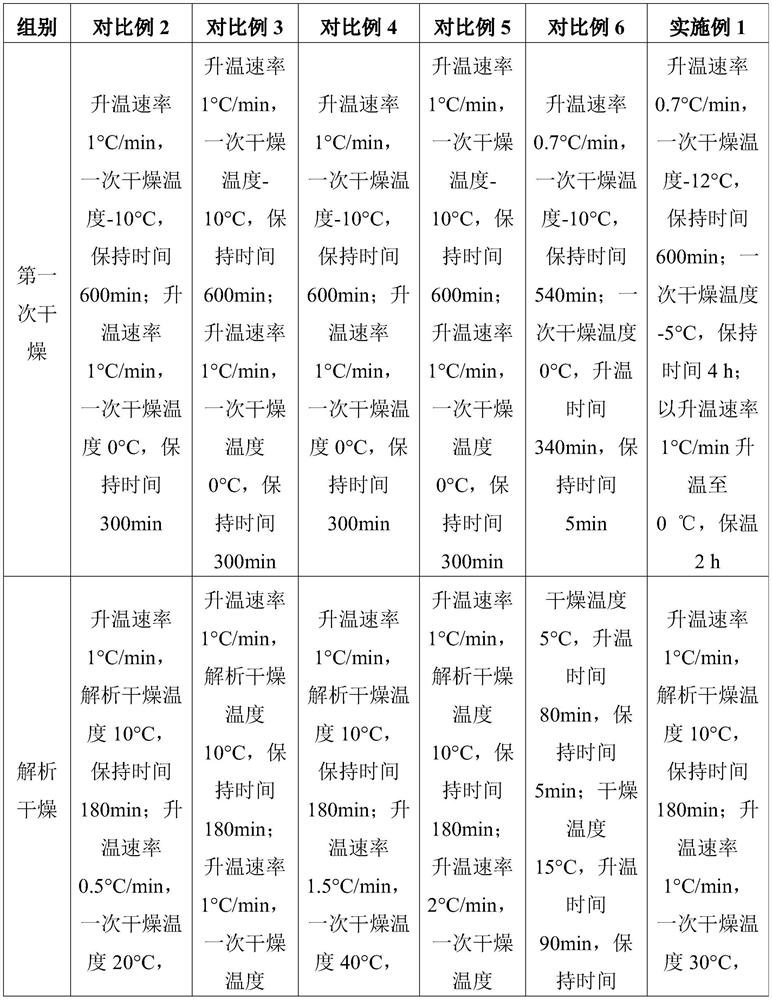

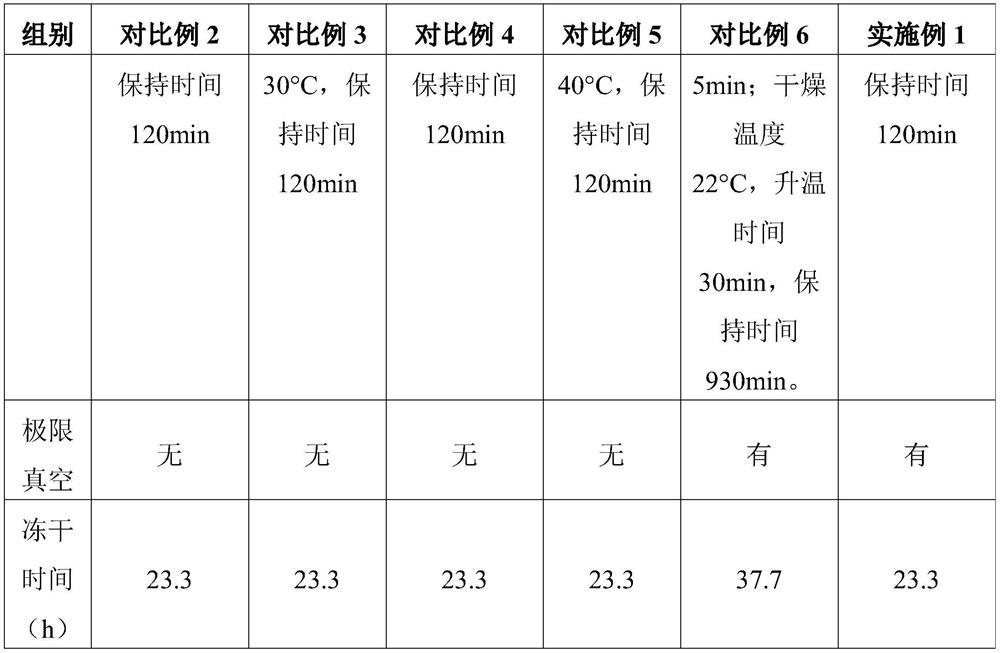

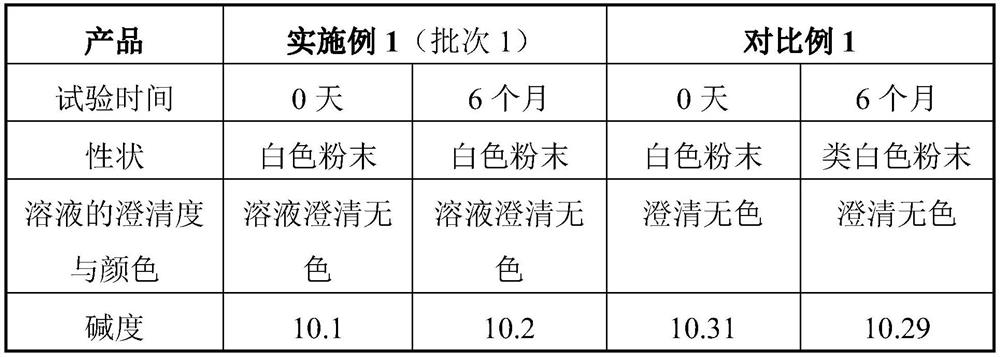

[0031] The preparation of embodiment 1 injection pantoprazole sodium freeze-dried preparation

[0032] In Example 1, batches 1, 2 and 3 are different batches of products prepared by the method in Example 1.

[0033] The prescription of this product is as follows Table 1:

[0034] Table 1 Product prescription

[0035] Raw materials unit dose Pantoprazole Sodium Sesquihydrate 45.1mg Edetate Disodium (for injection) 1mg sodium hydroxide 0.24mg Water for Injection Add to 2ml

[0036] Take the water for injection below 30°C, inject nitrogen gas, add water for injection according to the amount of 95% of the water for injection in the prescription amount, cool the water for injection below 30°C, fill with nitrogen gas, and weigh edetate disodium according to the prescription amount Put it into the liquid mixing tank, and circulate and stir for at least 5 minutes until it is completely dissolved; add a part of sodium hydroxide solution, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com