Starch-modified polycarboxylic acid macromonomer and preparation method thereof

A starch modification and polycarboxylic acid technology, which is applied in the field of polycarboxylic acid macromonomers, can solve the problems of low comprehensive cost performance of polycarboxylic acid macromonomers, and achieves favorable construction operation, strong adaptability and good adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

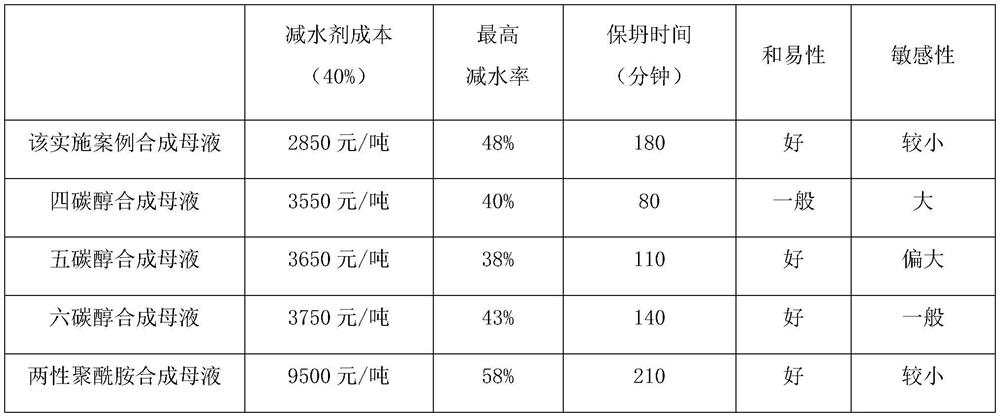

Embodiment 1

[0028]Add 30 parts of propylene glycol and 0.2 parts of catalyst succinic acid to 100 parts of corn starch, stir under normal pressure, raise the temperature to 90°C, continue stirring for 2 hours, increase the temperature to 100°C, add 4 parts of methallyl alcohol polyoxyethylene in batches Ether (addition number of ethylene oxide is 8), vacuumize to -0.085Mpa, add 3 parts of methallyl alcohol polyoxyethylene ether (addition number of ethylene oxide is 16) after 1 hour, the temperature is raised to 110°C, after another 1.5 hours, add 6 parts of isopentenol polyoxyethylene ether (addition number of ethylene oxide is 30), increase the temperature to 125°C, really increase to -0.098Mpa, maintain for 2 hours, and recover at the same time propylene glycol. Return the pressure in the kettle to normal pressure, add 1 part of monochloroacetic acid, carry out the esterification reaction for 2.5 hours, the temperature is controlled at 125 ° C, and the by-product water is evaporated dur...

Embodiment 2

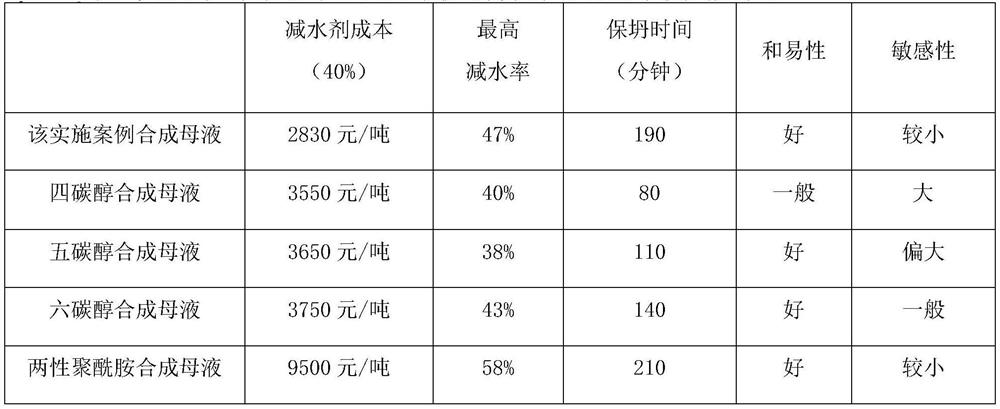

[0033] Add 25 parts of propylene glycol and 0.5 parts of catalyst succinic acid to 100 parts of corn starch, stir under normal pressure, raise the temperature to 90°C, continue stirring for 2 hours, raise the temperature to 95°C, add 6 parts of methallyl alcohol polyoxyethylene in batches Ether (addition number of ethylene oxide is 8), vacuumize to -0.085Mpa, add 4 parts of methallyl alcohol polyoxyethylene ether (addition number of ethylene oxide is 16) after 1 hour, the temperature is raised to 110°C, after another 1.5 hours, add 6 parts of isopentenol polyoxyethylene ether (addition number of ethylene oxide is 30), increase the temperature to 125°C, really increase to -0.098Mpa, maintain for 2 hours, and recover at the same time propylene glycol. Return the pressure in the still to normal pressure, add 2 parts of monochloroacetic acid, carry out the esterification reaction for 2.5 hours, the temperature is controlled at 125 ° C, and the by-product water is evaporated during...

Embodiment 3

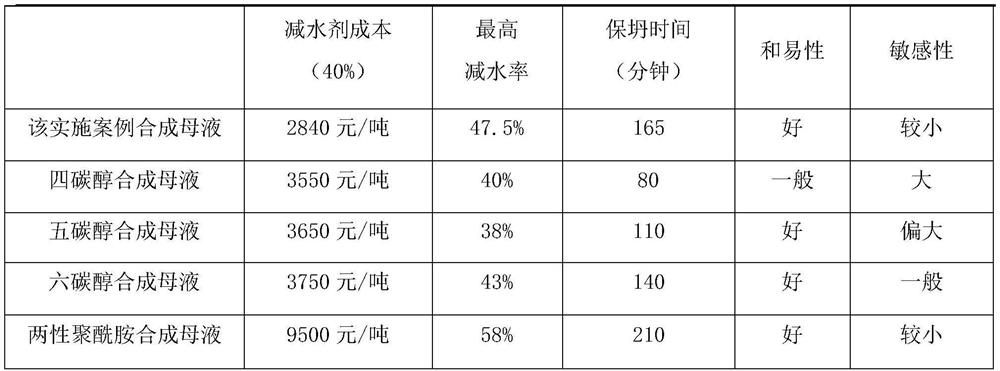

[0038] Add 30 parts of propylene glycol and 0.5 parts of catalyst succinic acid to 100 parts of corn starch, stir under normal pressure, raise the temperature to 90°C, continue stirring for 2 hours, increase the temperature to 100°C, add 4 parts of methallyl alcohol polyoxyethylene in batches Ether (addition number of ethylene oxide is 8), vacuumize to -0.085Mpa, add 6 parts of methallyl alcohol polyoxyethylene ether (addition number of ethylene oxide is 16) after 1 hour, the temperature is raised to 110°C, after another 1.5 hours, add 3 parts of isopentenol polyoxyethylene ether (the addition number of ethylene oxide is 30), increase the temperature to 120°C, and really increase it to -0.098Mpa, keep it for 2 hours, and recover at the same time propylene glycol. Return the pressure in the still to normal pressure, add 2 parts of monochloroacetic acid, carry out the esterification reaction for 2.5 hours, the temperature is controlled at 125 ° C, and the by-product water is eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com