High-efficiency ecological management salvaging device and salvaging method

A technology of ecological management and salvage device, which is applied to the cleaning of open water, grain processing, water conservancy projects, etc. It can solve the problems of increasing equipment footprint, reducing work efficiency, and jamming, so as to reduce maintenance costs and improve work efficiency , to ensure the effect of synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

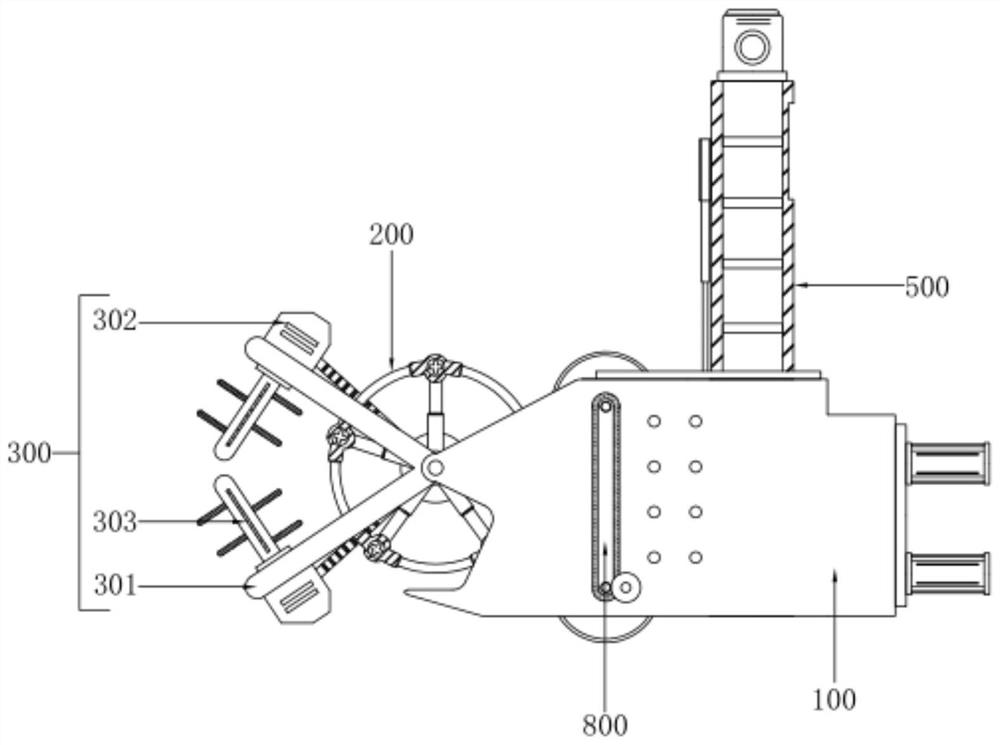

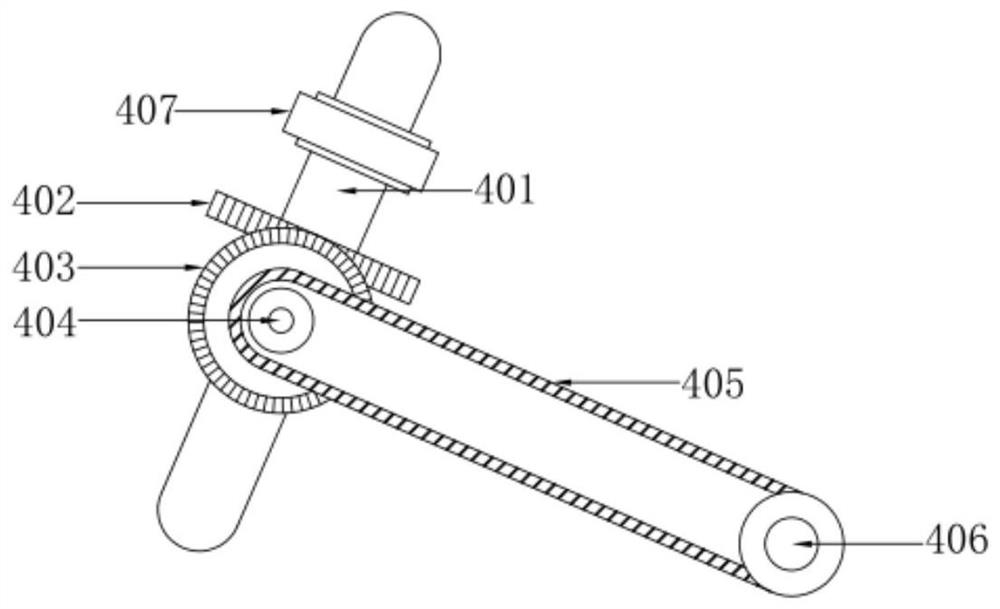

[0031] Embodiment 1: The present invention provides a kind of high-efficiency ecological management fishing device, please refer to figure 1 , including a box body 100 with an open front end and several water-permeable holes on the surface. The front end of the box body 100 is provided with an axial cutting assembly 200 mounted on a rotating shaft 101. The rotating shaft 101 is driven by a waterproof motor 102, and the waterproof motor 102 The axial cutting assembly 200 is driven to perform axial cutting operations on the sundries in the water surface. The radial cutting assembly 300 is arranged on the front side of the axial cutting assembly 200, and the sundries in the water surface are radially cut through the radial cutting assembly 300. For cutting operation, the radial cutting assembly 300 is driven and connected with the axial cutting assembly 200 through the linkage assembly 400, and the axial cutting assembly 200 and the radial cutting assembly 300 are linked through t...

Embodiment 2

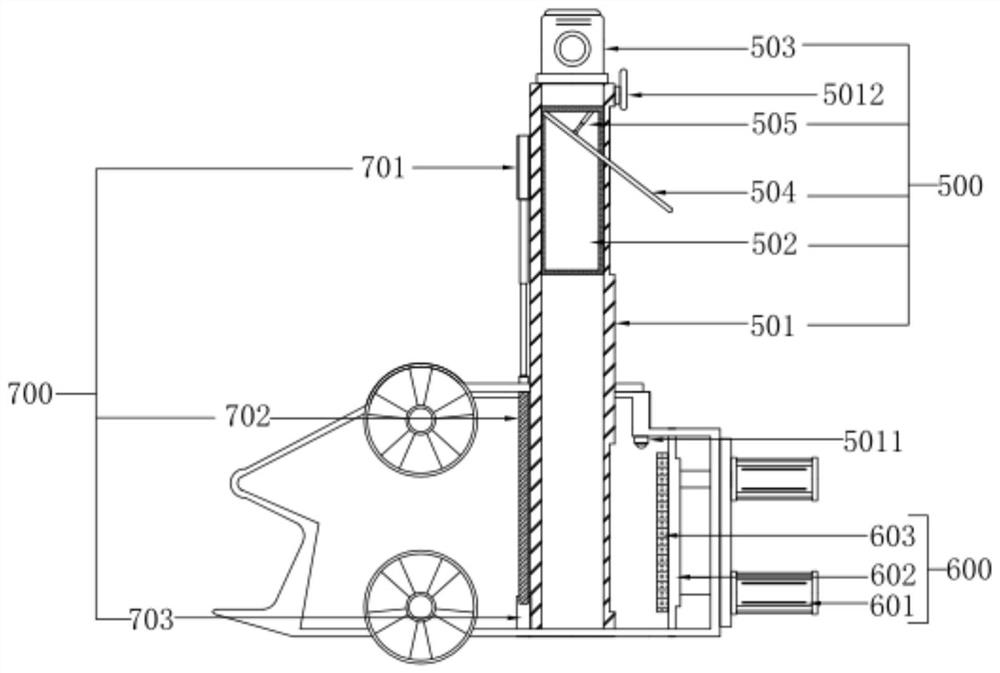

[0035] Embodiment 2: what this embodiment is different from above-mentioned embodiment is: please refer to figure 1 and figure 2 , the material lifting assembly 500 includes a guide frame 501 vertically fixedly plugged into the box body 100, the bottom of the guide frame 501 extends to the bottom of the inner cavity of the box body 100, an opening is opened on the top surface of the box body 100, and a lifting mechanism is provided on the top of the guide frame 501 503, the lifting mechanism 503 includes a lifting motor, a lifting roller and a steel wire rope connected to the material storage frame 502, and the inner cavity of the guide frame 501 is provided with a material storage frame 502, and the material storage frame 502 is adapted to the shape of the inner cavity of the guide frame 501 and Slidingly connected, its lifting is controlled by the lifting mechanism 503. The vertical surface of the material storage frame 502 is a rotating baffle 504, which is rotatably conne...

Embodiment 3

[0037] Embodiment 3: what this embodiment is different from above-mentioned embodiment is: please refer to figure 2 , one side of the guide frame 501 is provided with a stopper assembly 700, the stopper assembly 700 includes a stopper 702 vertically movably inserted on the box body 100, the top surface of the box body 100 is provided with a plate opening, and the bottom end of the stopper 702 is It is movably plugged on the base 703, and the top of the baffle plate 702 is fixedly connected with the output end of the cylinder rod 701 arranged on the side wall of the guide frame 501. When the debris inside floats into the guide frame 501 side, the control material baffle plate 702 rises, and when the debris is pressed and lifted, the control material baffle plate 702 descends to stop the continuation of the debris.

[0038] see figure 2 , an underwater probe 5011 is provided near the guide frame 501 in the inner cavity of the top surface of the box body 100, and the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com