Low-cost hierarchical pore SAPO-34 molecular sieve and preparation method and application thereof

A multi-stage pore, molecular sieve technology, applied in molecular sieve and alkali exchange phosphate, separation method, molecular sieve catalyst, etc., can solve the problem of high cost, achieve excellent low temperature activity, significant social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Concrete, the preparation method of low-cost multi-stage porous SAPO-34 molecular sieve, it comprises the following steps:

[0035] A. Lithium silicon powder is washed with acid, dried and sieved to obtain powder;

[0036] B. Mix water and phosphorus source evenly to obtain phosphorus source solution;

[0037] C. Mix the powder obtained in step A with the phosphorus source solution obtained in step B, then add the templating agent under stirring, and mix evenly to obtain a mixed solution;

[0038] D. After the mixed solution obtained in step C is aged at room temperature, the temperature is raised to carry out hydrothermal crystallization to obtain a crystallization solution;

[0039] E. The crystallization solution obtained in step D is cooled, washed, filtered, dried and calcined to obtain low-cost multi-stage SAPO-34 molecular sieve.

[0040]Lithium silicon powder is a kind of industrial waste produced by the process of calcining spodumene at high temperature in th...

Embodiment 1

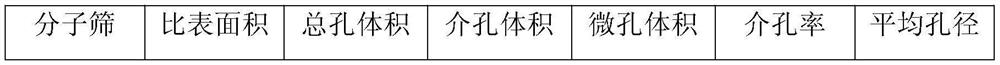

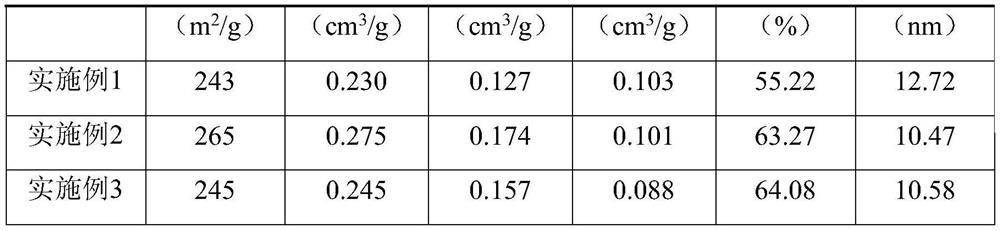

[0054] 4.16mLH 3 PO 4 Dissolve in 36mL deionized water, place on a magnetic stirrer and stir vigorously for 30min, add 3.34gAl 2 o 3 , continue to stir vigorously for 90 minutes, then slowly add 4 g of lithium silicon powder washed with 3 mol / L hydrochloric acid and dried through a 200-mesh sieve, stir for 60 minutes, then add 16.64 mL of template agent triethylamine, and stir vigorously for 90 minutes to form a uniform mixture. The mixed solution was filled into a polytetrafluoroethylene liner and sealed into a stainless steel reactor. After aging at room temperature for 12 hours, the temperature was raised to 200°C at a rate of 2°C / min and kept for 24h. After the reaction kettle is cooled, take out the mixed solution, wash it with deionized water until it is neutral, and dry it in an oven at 105°C for 12 hours to obtain the original powder of molecular sieve. ℃ in a tube furnace for 5 hours to remove the template agent, and the heating rate is 2 ℃ / min to obtain the SAPO-3...

Embodiment 2

[0056] 4.16mLH 3 PO 4 Dissolve in 36mL deionized water, place on a magnetic stirrer and stir vigorously for 30min, add 3.89gAl 2 o 3 , continue to stir vigorously for 90 minutes, then slowly add 1 g of lithium silica powder washed with 3 mol / L hydrochloric acid and dried through a 200-mesh sieve, stir for 60 minutes, then add 16.64 mL of template triethylamine, and stir vigorously for 90 minutes to form a uniform mixture. The mixed solution was filled into a polytetrafluoroethylene liner and sealed into a stainless steel reactor. After aging at room temperature for 12 hours, the temperature was raised to 200°C at a rate of 2°C / min and kept for 24h. After the reaction kettle is cooled, take out the mixed solution, wash it with deionized water until it is neutral, and dry it in an oven at 105°C for 12 hours to obtain the original powder of molecular sieve. ℃ in a tube furnace for 5 hours to remove the template agent, and the heating rate is 2 ℃ / min to obtain the SAPO-34 molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com