Nano-silver dispersion liquid and preparation method thereof

A nano-silver and dispersion technology, applied in nanotechnology, sol preparation, nanotechnology, etc., can solve the problems of large nano-silver particle size, easy agglomeration, and affecting the antibacterial performance of nano-silver dispersion, and achieve simple operation and dispersion good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

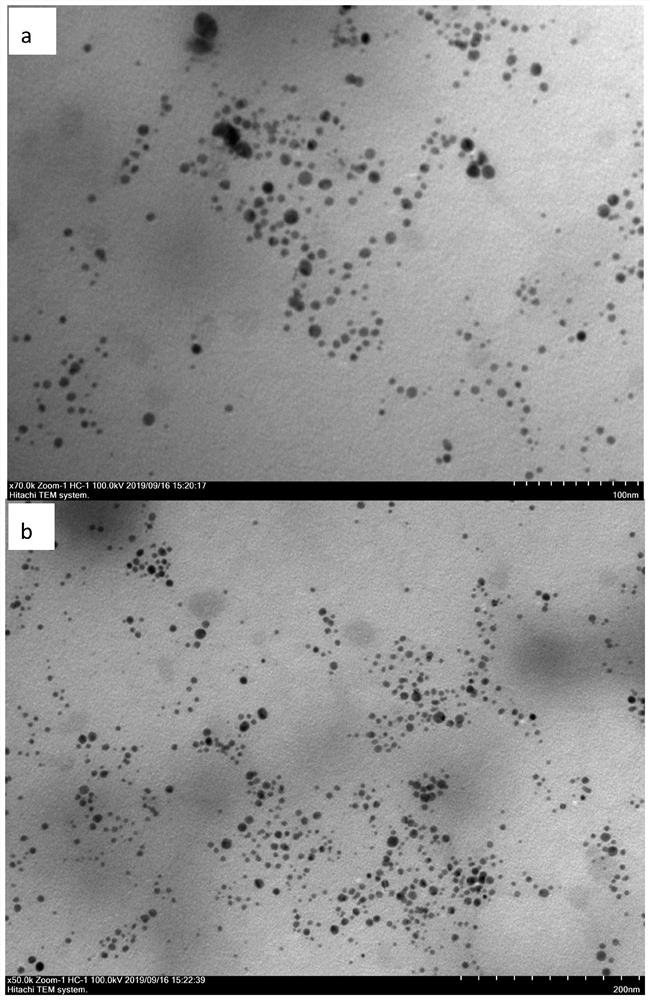

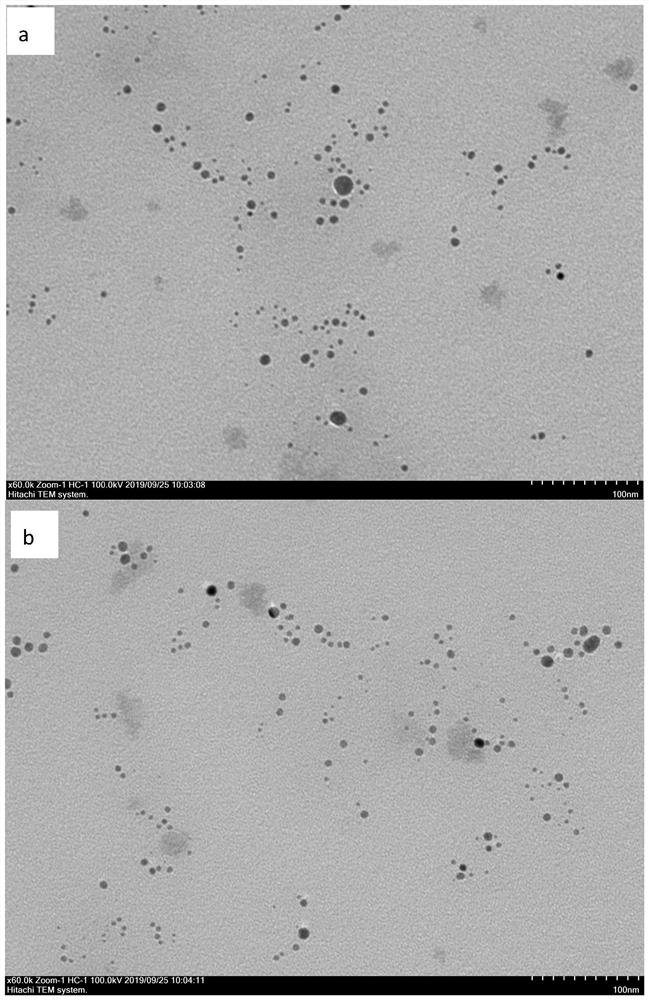

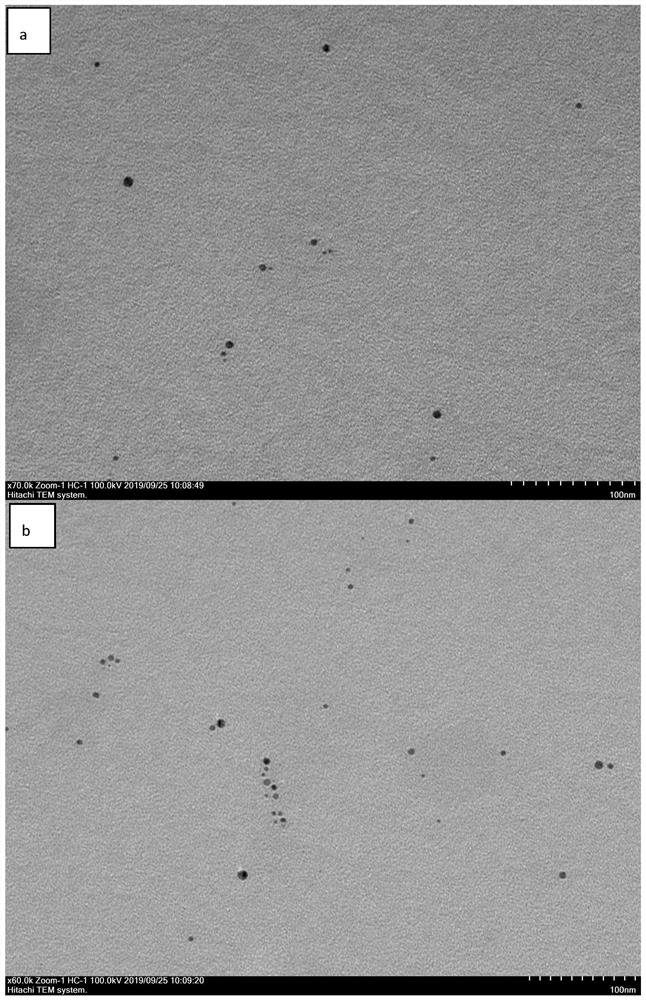

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of nano-silver dispersion liquid, comprises the following steps:

[0030] Mix γ-aminopropyltriethoxysilane, polyvinylpyrrolidone, sodium lauryl sulfate, silver nitrate and water to form a chelating action to obtain a chelated dispersion; before the mixing, γ-aminopropyltriethoxysilane Ethoxysilane is placed in the air for less than 5 minutes;

[0031] The sodium borohydride solution is added dropwise into the chelate dispersion, and an oxidation-reduction reaction occurs to obtain a nano-silver dispersion.

[0032] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0033] The invention mixes gamma-aminopropyltriethoxysilane, polyvinylpyrrolidone, sodium lauryl sulfate, silver nitrate and water for chelation to obtain a chelation dispersion.

[0034] In the present invention, after the mixing, the present invention preferably stirs ...

Embodiment 1

[0049] Put 0.3g of polyvinylpyrrolidone (PVP), 0.3g of sodium lauryl sulfate, 0.1g of silver nitrate and 0.26g of γ-aminopropyltriethoxysilane (KH-550, ready to use) in 89.034g of distilled water In a magnetic stirrer, stir at room temperature at a rate of 2000r / s for 30s for chelation to obtain a chelation dispersion;

[0050] Add 0.006g of sodium borohydride into 10g of distilled water and stir to dissolve to obtain a sodium borohydride solution;

[0051] Under the condition of stirring (2000r / s), the sodium borohydride solution is continuously added dropwise (1 drop per second) into the chelate dispersion, after the dropwise addition is completed, the nano-silver dispersion (dark brown without precipitation) is obtained, Wherein, the mass fraction of nano-silver is 0.06%.

Embodiment 2

[0053] The only difference with Example 1 is that the sodium borohydride solution is added dropwise in the chelating dispersion liquid every 5s, and after the dropwise addition is completed, the nano-silver dispersion (dark brown without precipitation) is obtained, wherein the mass of the nano-silver The score is 0.06%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com