1260 DEG C biosoluble environment-friendly refractory fiber and preparation process thereof

A refractory fiber and preparation technology, which is applied in the field of refractory fiber materials, can solve the problems of poor high temperature resistance to atmosphere, short service life, easy crystallization and pulverization, etc., and achieve the effects of protecting the environment, improving high temperature performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

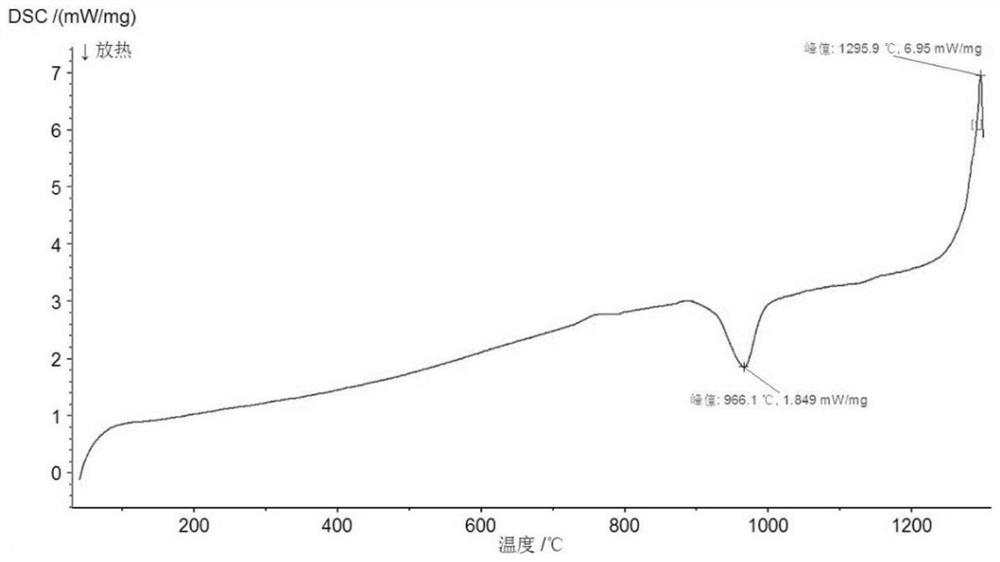

Embodiment 1

[0060] According to the recipe: SiO 2 67.9%, CaO 15.12%, MgO 9.75%, ZrO 2 5.57%, weigh 65.5kg of quartz sand, 16.8kg of lime, 10kg of magnesia and 7.7kg of zircon sand as raw materials, and follow the above-mentioned mixing-cloth-melting-spinning into fiber-collecting cotton-post-treatment Preparation process The product of Example 1 of the present invention was prepared.

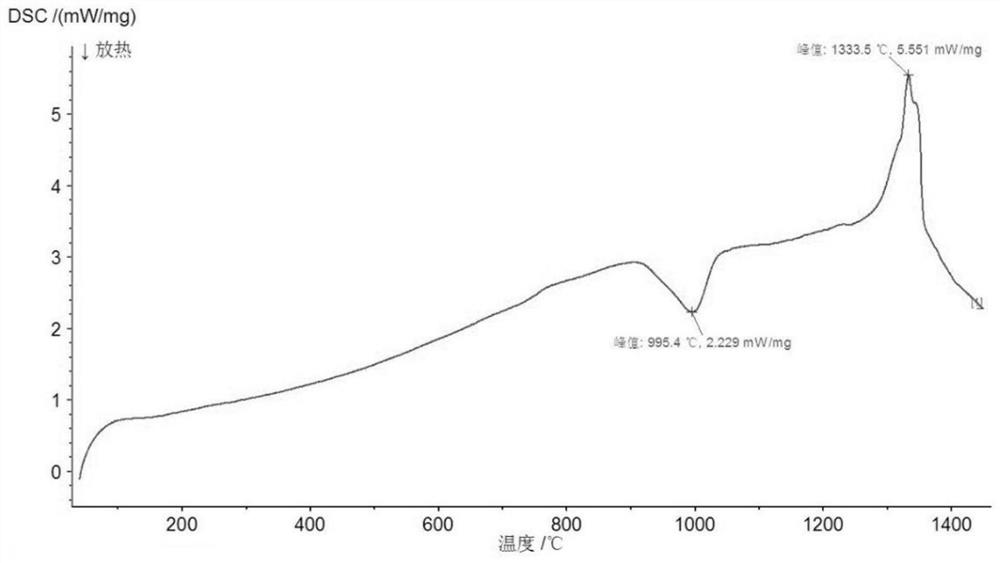

[0061] Embodiments 2 to 5 respectively adopt different raw material formulas—formulations 2 to 5, in terms of weight percentages, and the specific formulas are shown in Table 2:

[0062] Table II

[0063]

[0064] According to the formula in Table 2, the raw materials were weighed respectively, and the products of Examples 2 to 5 of the present invention were prepared according to the same preparation process as in Example 1, as shown in Table 3:

[0065] Table three

[0066]

[0067] Taking the common C2 aluminum silicate ceramic fiber with a temperature grade of 1260°C as comparative example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com