Monoammonium phosphate suspension fertilizer containing medium trace elements, and preparation method thereof

A technology of medium and trace elements and monoammonium phosphate, which is applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., and can solve the problem of high cost of raw material compounding, solid-liquid separation of suspended fertilizer, crystal growth and agglomeration, etc. problem, achieve the effect of avoiding caking and layering problems, stimulating plant physiological metabolism, and being resistant to storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the monoammonium phosphate suspension fertilizer containing medium and trace elements of the present invention comprises the steps:

[0033] a. Chelating reaction: mix concentrated phosphoric acid with chelating agent and suspending agent, heat up to 50-120°C and stir for 30-60 minutes to obtain a chelated solution; wherein, the concentrated phosphoric acid contains medium and trace elements;

[0034] b. Ammonification reaction: Ammonia gas is introduced into the solution after chelation until the pH value is 4.0-5.5, and the reaction is performed at a constant temperature of 80-120°C for 20-60 minutes to obtain a high-temperature monoammonium phosphate feed solution containing medium and trace elements;

[0035] c. Cooling molding: the high-temperature monoammonium phosphate feed liquid containing medium and trace elements is cooled to obtain the monoammonium phosphate suspension fertilizer containing medium and trace elements.

[0036] The pr...

Embodiment 1

[0058] The following method is used to prepare the monoammonium phosphate suspension fertilizer containing medium and trace elements and high solid content:

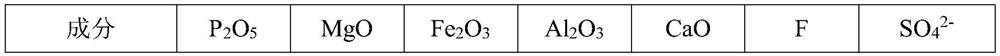

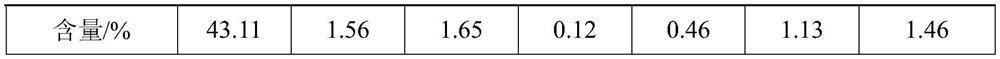

[0059]a. Chelating reaction: the concentrated wet-process phosphoric acid raw material, whose composition is shown in Table 1-1, is heated up to 80°C, and citric acid is added to it according to the content of trace elements in the concentrated wet-process phosphoric acid, and the addition amount is 2.0 times the theoretical amount, then add carboxymethyl cellulose to the solution, the amount added is 0.03% of the concentrated phosphoric acid, and stir at 80°C for 30 minutes;

[0060] b. Ammonification reaction: Ammonia gas is passed into the solution mixed uniformly in step a until the pH value is 4.5, and the reaction is held at a constant temperature of 100°C for 40 minutes, and a high-concentration monoammonium phosphate solution containing trace element nutrients in a chelated state is obtained at a high temperature ...

Embodiment 2

[0068] The following method is used to prepare the monoammonium phosphate suspension fertilizer containing medium and trace elements and high solid content:

[0069] a. Chelating reaction: the concentrated wet-process phosphoric acid raw material, whose composition is shown in Table 2-1, is heated up to 100°C, and EDTA is added to it according to the content of trace elements in the concentrated wet-process phosphoric acid, and the addition amount is theoretical 1.0 times of the dosage, then add carboxymethyl cellulose to the solution after chelation, the addition amount is 0.03% of the concentrated phosphoric acid, stir at 80°C for 30min;

[0070] b. Ammonification reaction: Introduce ammonia gas into the solution mixed uniformly in step a until the pH value is 4.6, stay at a constant temperature at 100°C for 40 minutes, and obtain a high-concentration monoammonium phosphate solution containing trace element nutrients in a chelated state at a high temperature ;

[0071] c. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com