Phosphorus-nitrogen composite flame retardant, and preparation method and application thereof

A composite flame retardant technology, applied in the field of fine chemicals, can solve problems such as poor water resistance, flammability of aluminum hypophosphite, poor compatibility, etc., achieve good hydrophobic properties, improve flame retardant performance, and ensure physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

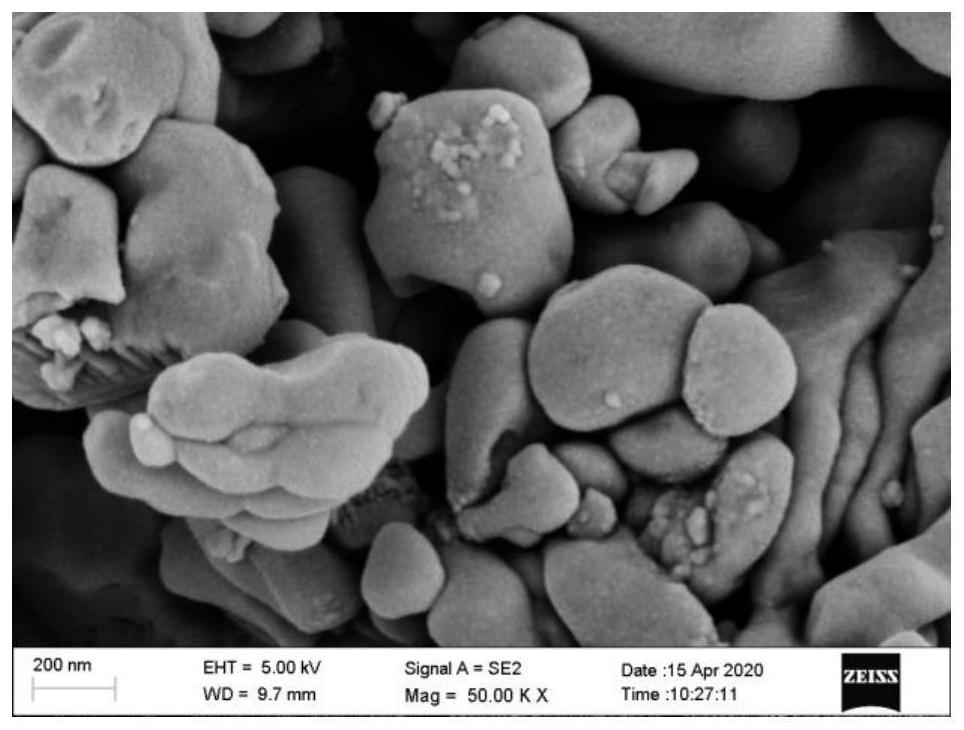

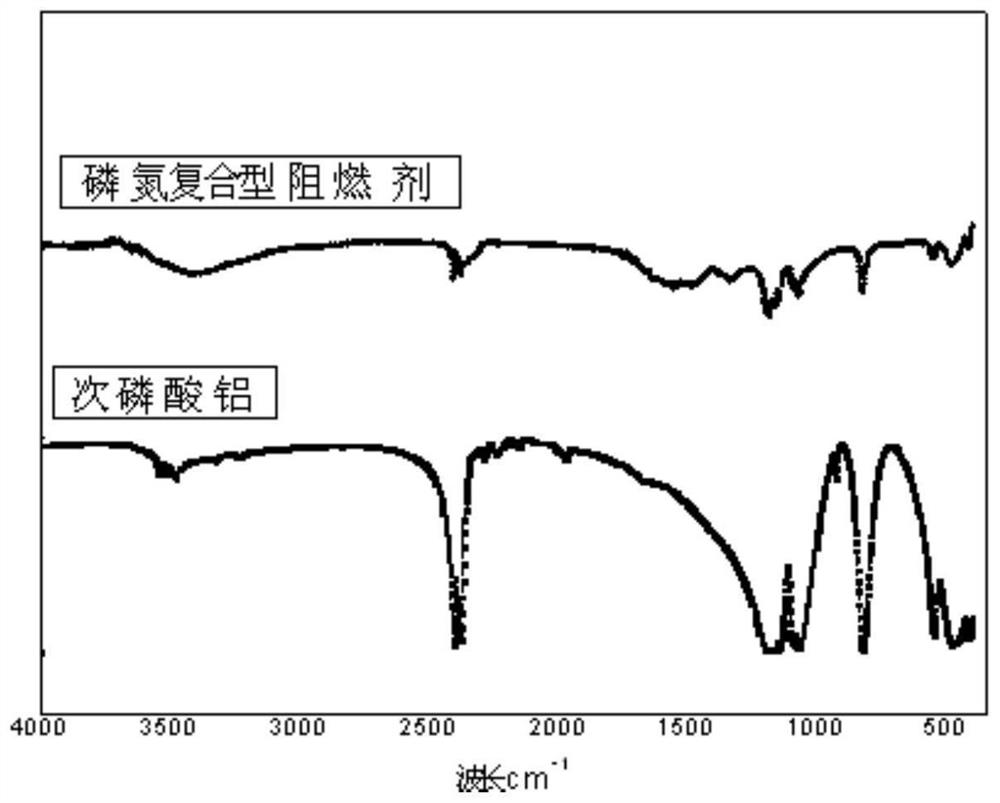

[0029] Preparation of Example 1 Phosphorus Nitrogen Composite Flame Retardant A

[0030] (1) Add 8 parts of water to the reaction kettle 1, start stirring, and raise the temperature to 95°C, then add 2 parts of hexamethylolmelamine to the reaction kettle, and add 0.8% hexamethylolmelamine mass fraction at the same time The anti-reverse agent melamine, continuous stirring to completely dissolve the hexamethylol melamine.

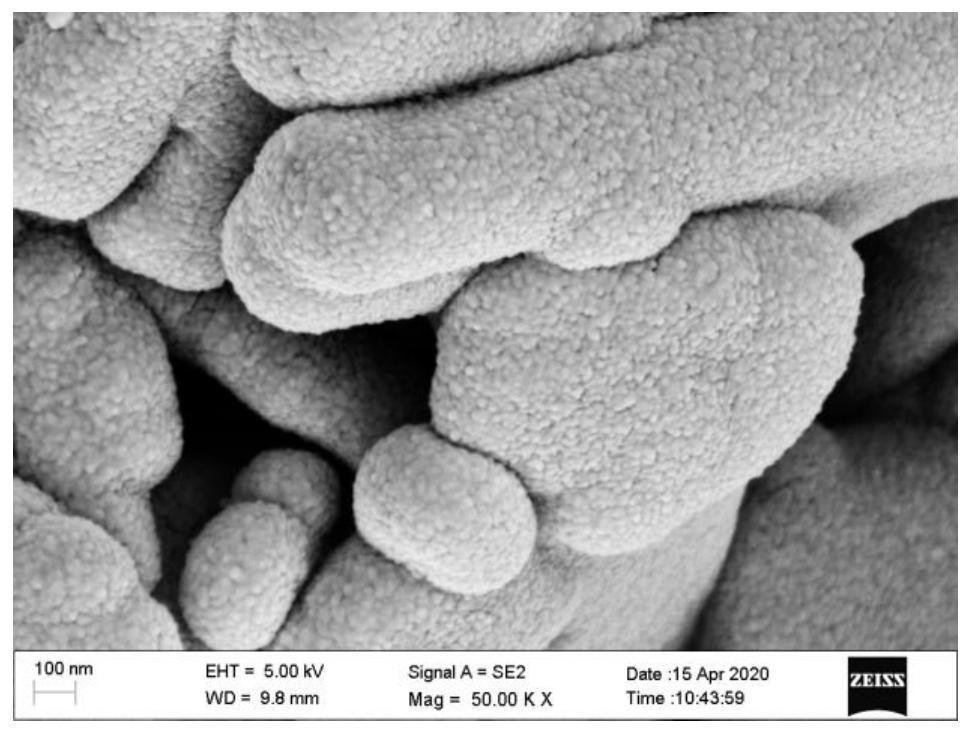

[0031] (2) Add 8 parts of water into the reaction kettle 2, start stirring and add 3 parts of aluminum hypophosphite, and continue stirring to obtain aluminum hypophosphite slurry.

[0032] (3) Add the aluminum hypophosphite slurry obtained in (2) into the reaction kettle 1, keep stirring, and add 0.08 parts of acetic acid dropwise to adjust the pH of the reaction solution to 4, continue the reaction at 95°C for 8 hours, and then Filtration, washing, and drying to obtain a phosphorus-nitrogen composite flame retardant. The obtained product A has an average ...

Embodiment 2

[0036] Preparation of Example 2 Phosphorus Nitrogen Composite Flame Retardant B

[0037] (1) Add 7 parts of water to the reaction kettle 1, start stirring, and raise the temperature to 85°C, then add 1.8 parts of hexamethylolmelamine to the reaction kettle, and add 0.8% hexamethylolmelamine mass fraction at the same time The anti-reverse agent melamine, continuous stirring to completely dissolve the hexamethylol melamine.

[0038] (2) Add 7 parts of water into the reaction kettle 2, start stirring and add 4.2 parts of aluminum hypophosphite, and continue stirring to obtain aluminum hypophosphite slurry.

[0039] (3) Add the aluminum hypophosphite slurry obtained in (2) into the reaction kettle 1, keep stirring, and dropwise add 0.06 parts of acetic acid to adjust the pH of the reaction solution to 3.5, and continue to react at 85°C for 7.5 hours. Suction filtration, washing, and drying to obtain a phosphorus-nitrogen composite flame retardant. The obtained product B has an a...

Embodiment 3

[0040] Preparation of Example 3 Phosphorus Nitrogen Composite Flame Retardant C

[0041] (1) Add 6 parts of water to the reaction kettle 1, start stirring, and raise the temperature to 105°C, then add 1.5 parts of hexamethylolmelamine to the reaction kettle, and add 0.8% hexamethylolmelamine mass fraction at the same time The anti-reverse agent melamine, continuous stirring to completely dissolve the hexamethylol melamine.

[0042] (2) Add 9 parts of water into the reaction kettle 2, start stirring and add 4.5 parts of aluminum hypophosphite, and continue stirring to obtain aluminum hypophosphite slurry.

[0043] (3) Add the aluminum hypophosphite slurry obtained in (2) into the reaction kettle 1, keep stirring, and dropwise add 0.1 part of acetic acid to adjust the pH of the reaction solution to 4.5, continue the reaction at 105°C for 6 hours, and then pump Filtration, washing, and drying to obtain a phosphorus-nitrogen composite flame retardant. The average particle diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com